Medicine tablet forming equipment

A technology for forming equipment and tablets, which is applied in the direction of material forming presses, devices for making drugs into special physical or ingestible forms, and solid separation, which can solve problems such as low work efficiency and inability to separate dust, and achieve improvement The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

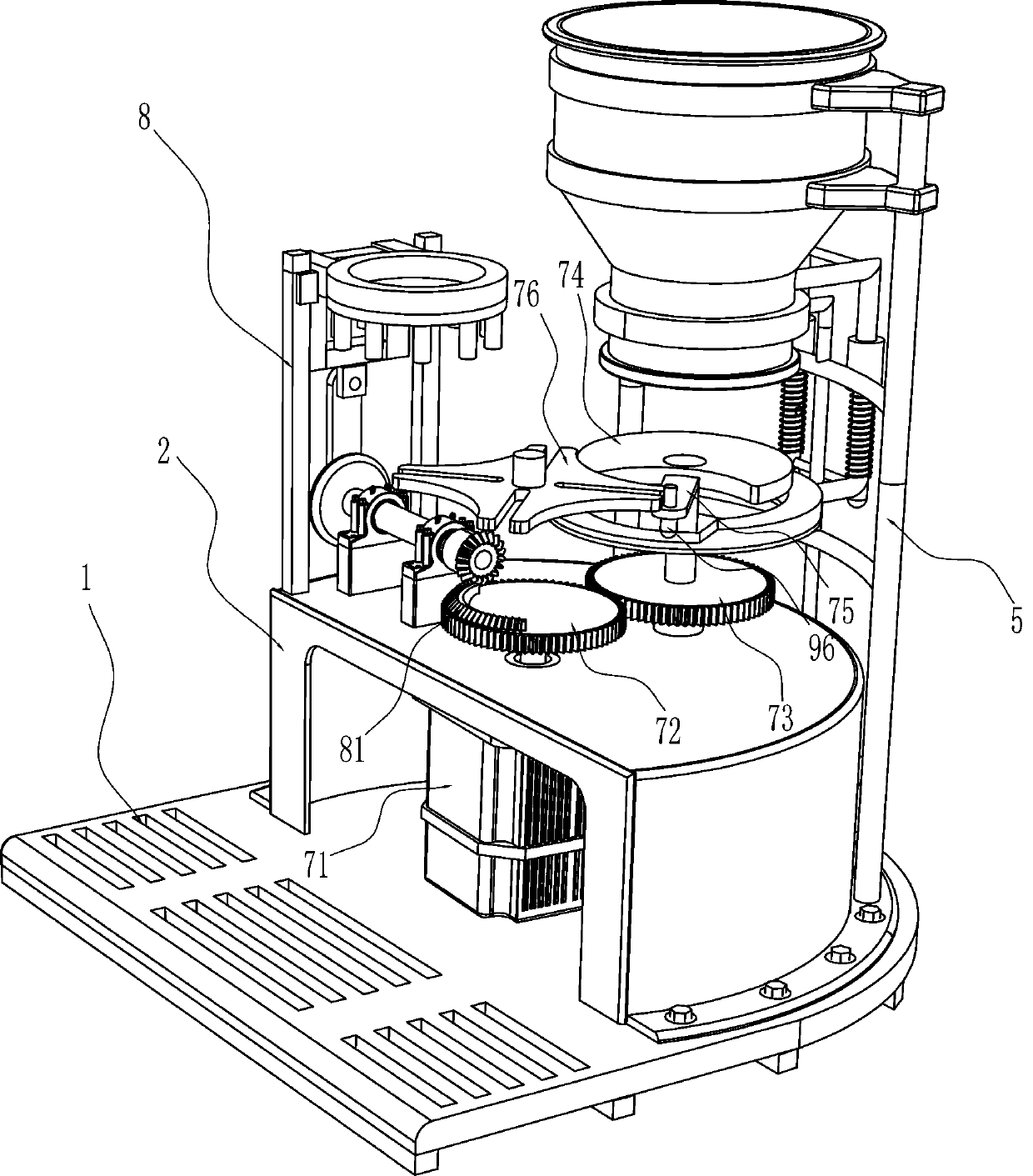

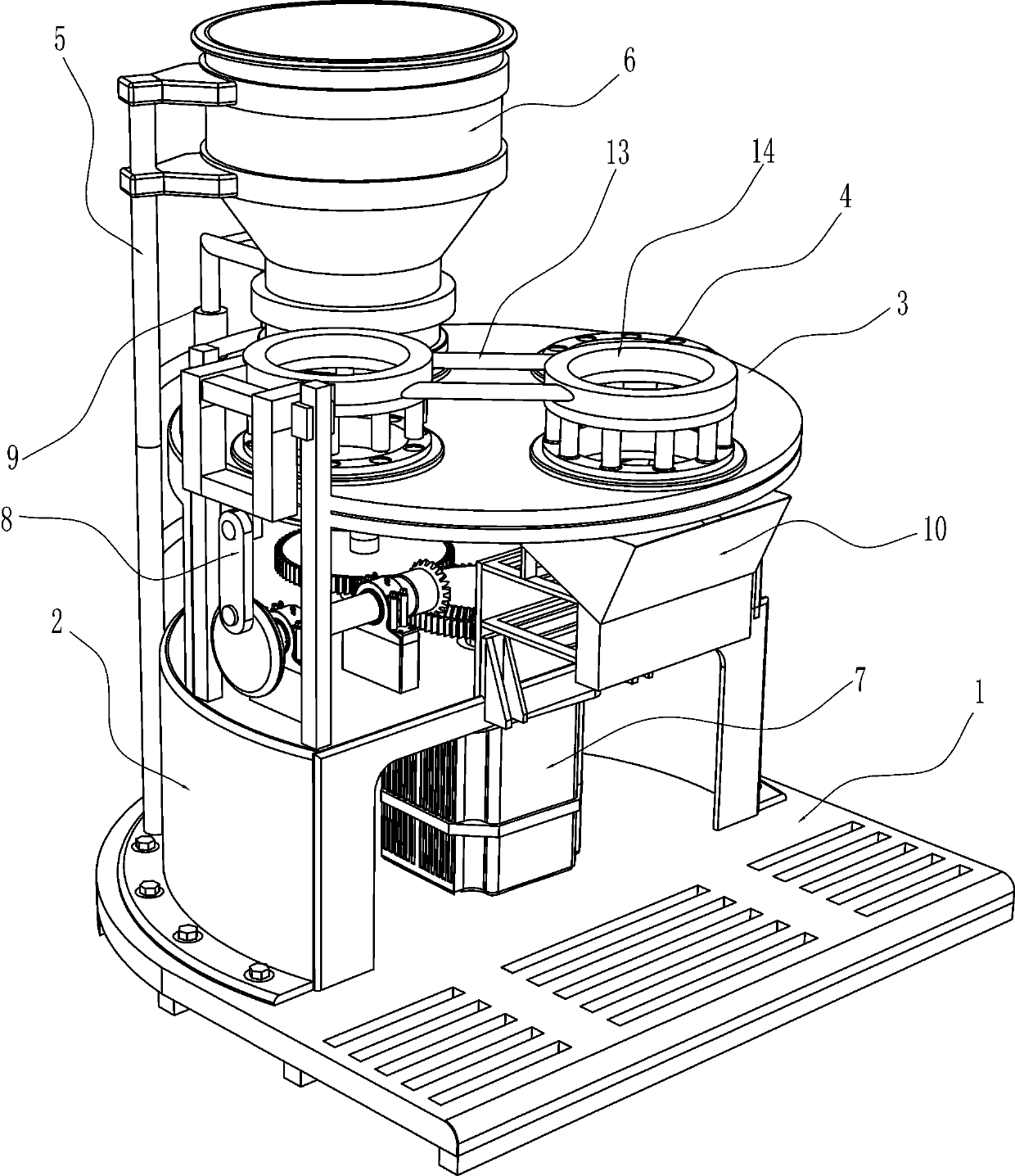

[0026] A tablet tablet forming equipment such as Figure 1-8 As shown, it includes a base 1, a mounting frame 2 and a turntable 3, the top of the base 1 is provided with a mounting frame 2, and the top of the mounting frame 2 is rotatably connected to a turntable 3, and the turntable 3 is horizontally arranged, and also includes a forming plate 4, a first Connecting frame 5, blanking assembly 6, driving assembly 7, briquetting assembly 8 and blanking hopper 10, four forming discs 4 are installed at uniform intervals along the circumferential direction on the turntable 3, and the forming discs 4 are connected to the turntable 3 by bolts. connection, the base 1 is connected with the first connecting frame 5, the first connecting frame 5 is located on the side of the mounting frame 2, the upper part of the first connecting frame 5 is provided with a blanking assembly 6, and the driving assembly is provided between the base 1 and the mounting frame 2 7. There is a briquetting asse...

Embodiment 2

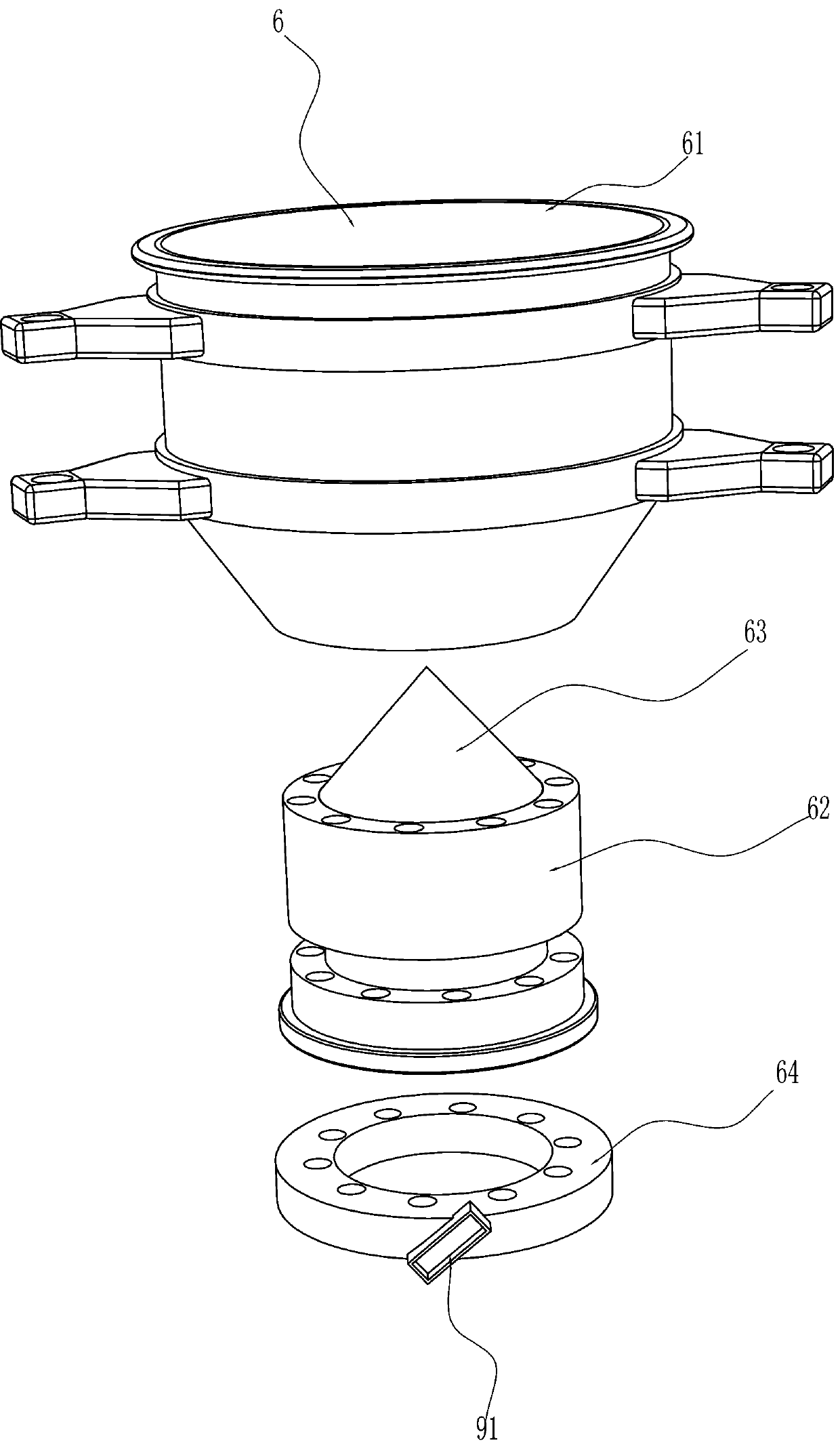

[0032] On the basis of Example 1, as Figure 4 and Figure 8 As shown, a transmission assembly 9 is also included, and the transmission assembly 9 includes a guide block 91, a guide sleeve 92, a bracket 93, a guide rod 94, a return spring 95, a contact rod 96 and a convex plate 97, and the set plate 64 is connected with a guide block 91, the guide block 91 is inclined at an angle of 45 degrees, the first connecting frame 5 is connected with a guide sleeve 92, the guide sleeve 92 is connected with the first connecting frame 5 by welding, and the guide sleeve 92 is slidingly connected with Support 93, support 93 is connected with distribution plate 62, is connected with back-moving spring 95 between guide sleeve 92 and support 93, and back-moving spring 95 is enclosed within on the support 93, and support 93 bottoms are connected with convex plate 97, and the shape of convex plate 97 is Ring-shaped and horizontally arranged, the first connecting frame 5 is connected with a guid...

Embodiment 3

[0035] On the basis of Example 2, such as Figure 9 As shown, it also includes a screen 11 and a discharge pipe 12, the bottom of the discharge hopper 10 is connected with a screen 11 and a discharge pipe 12, the screen 11 is connected to the discharge hopper 10 in a detachable manner, and the discharge pipe 12 passes through The mode of welding connection is connected with the discharge hopper 10, and the discharge pipe 12 is positioned at the rear side of the screen cloth 11.

[0036] After the tablet falls into the hopper 10 , the tablet continues to fall through the slope inside the hopper 10 , the powder in the tablet is sieved out by the screen 11 , and the tablet continues to slide down and falls out through the hopper 12 .

[0037] Such as Figure 10 As shown, it also includes a second connection frame 13 and an extrusion disc 14, the second connection frame 13 is connected on the pressure plate 87, the extrusion disc 14 is connected on the second connection frame 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com