Cleaning device for bar-like material conveying pipeline

A technology for conveying pipelines and cleaning devices, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve the problems of low degree of automation, time-consuming fault pipeline search, low production efficiency, etc., and achieve the goal of simplifying the system structure and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further detail below through specific embodiments.

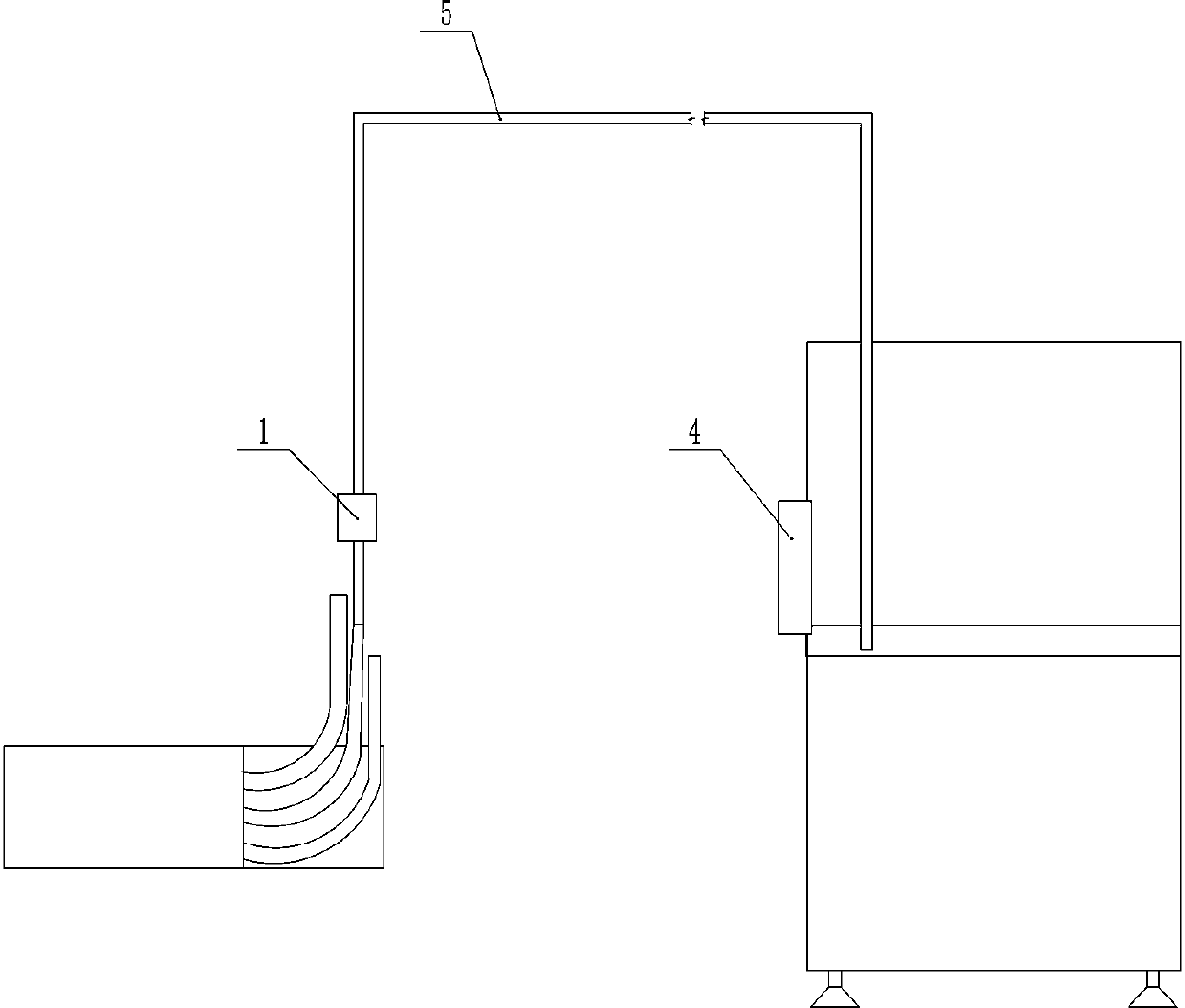

[0023] Such as Figure 1-Figure 4 As shown, a cleaning device for a rod-shaped material conveying pipeline includes a blowback valve 1, a solenoid valve 2, a high-pressure air source, a delay valve 3 and a control device 4, and the blowback valve 1 is installed at the tail end of the conveying pipeline 5 , the control device 4 is installed at the front end of the conveying pipeline 5, and the blockage of the conveying pipeline 5 is judged manually or automatically detected by the pneumatic conveying device according to changes in air pressure.

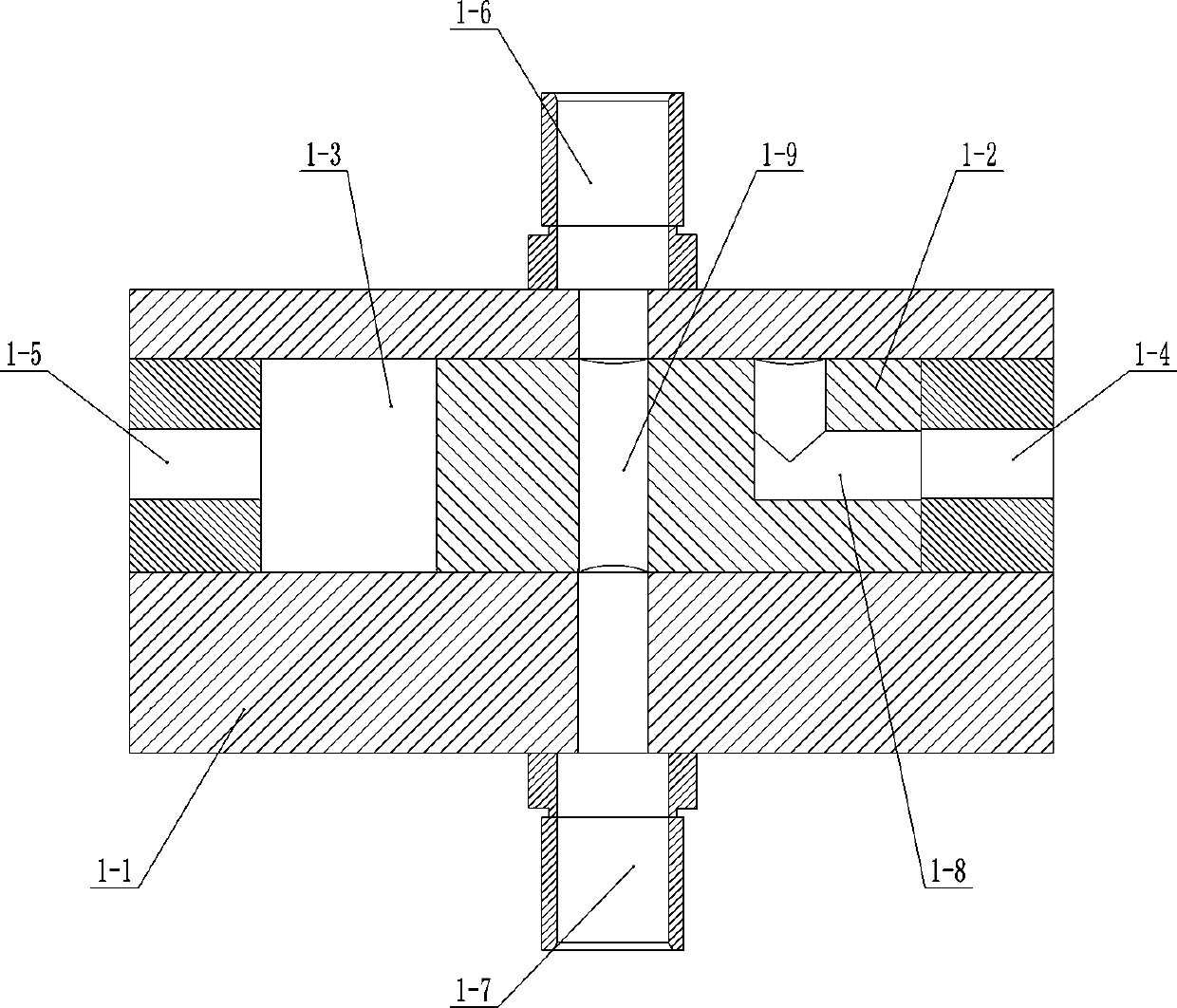

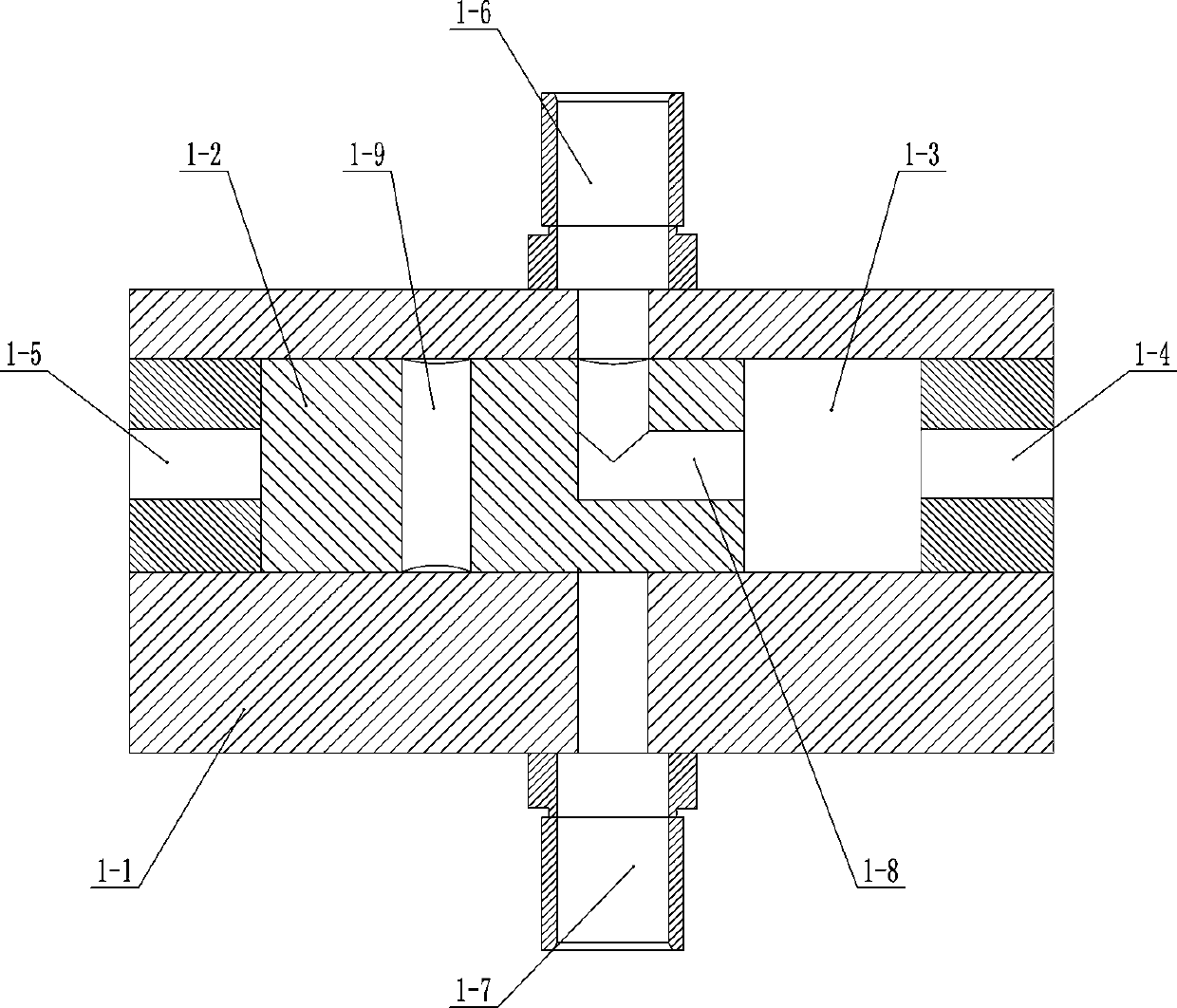

[0024] The blowback valve, electromagnetic valve and delay valve are all pneumatic valves, the blowback valve 1 includes a valve body 1-1 and a valve core 1-2, and a valve cavity 1-3 is arranged in the valve body 1-1, so The spool 1-2 is horizontally slidably installed in the valve cavity 1-3, the spool 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com