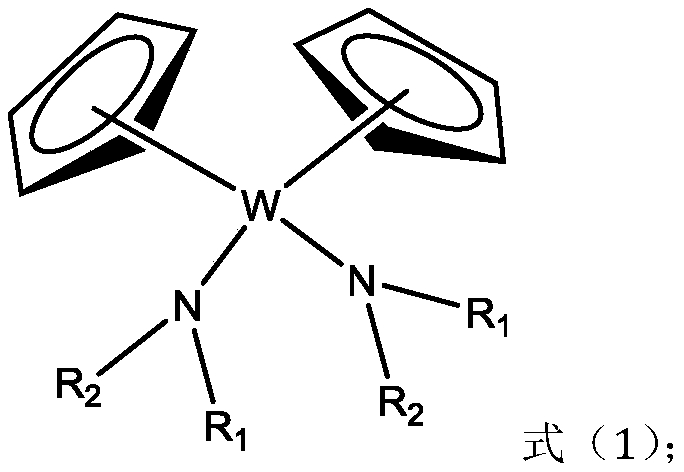

Tungsten complex and preparation method and application thereof

A technology of complexes and adducts, applied in chemical instruments and methods, bulk chemical production, organic chemistry, etc., can solve the problems of high cost, limited application, and many uncontrollable parameters, and achieve high saturated vapor pressure and no Potential safety hazards, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment relates to a preparation method of a tungsten complex, carried out in a reaction vessel protected by a high-purity argon atmosphere, comprising the following steps:

[0027] Step 1: Add 15 grams of tungsten hexachloride and 50 milliliters of dichloromethane to a 250 milliliter Schlenk bottle in sequence, and slowly add 34 milliliters of cyclopentene dropwise while stirring, keep the temperature of the system at 45°C, and reflux for 30 minutes Afterwards, vacuum suction filtration, add 20 milliliters of ethylene glycol dimethyl ether to the filtrate, continue to react for 30 minutes, vacuum suction filtration, the filter residue is washed three times with 10 milliliters of methyl tert-butyl ether and vacuum-dried to obtain tungsten tetrachloride 13 grams of glycol dimethyl ether adduct, yield 85%;

[0028] Step 2: Add 14 g of cyclopentadienyllithium, 600 ml of methyl tert-butyl ether and 40 g of tungsten tetrachloride ethylene glycol dimethyl ether prepar...

Embodiment 2

[0032] This embodiment relates to a preparation method of a tungsten complex, carried out in a reaction vessel protected by a high-purity argon atmosphere, comprising the following steps:

[0033] Step 1: Add 120 grams of tungsten hexachloride and 400 milliliters of dichloromethane to a 2-liter Schlenk bottle; slowly add 300 milliliters of cyclopentene dropwise while stirring to keep the temperature of the system at 50 ° C, and reflux for 2 hours , return to room temperature, vacuum filter, add 160 milliliters of ethylene glycol dimethyl ether to the filtrate, continue to react for 2 hours, vacuum filter, filter residue is vacuum-dried after washing three times with 100 milliliters of methyl tert-butyl ether, obtain tetrachloro 110 grams of tungsten chloride ethylene glycol dimethyl ether adduct, yield 90%;

[0034] Step 2: Add 14 g of cyclopentadienyllithium, 600 ml of methyl tert-butyl ether and 40 g of tungsten tetrachloride ethylene glycol dimethyl ether prepared by the me...

Embodiment 3

[0037] Different from Example 1, this example only replaces 22 grams of lithium dimethylamide in step 3 of Example 1 with 34 grams of lithium diethylamide, and finally obtains the product bis(diethylamino) The yield of bis(cyclopentadienyl)tungsten is 86%, and the saturated vapor pressure at 69°C is 1.2mmHg. The product was detected by nuclear magnetic resonance, and the results were as follows, 1 HNMR (CDCl 3 ): 4.15, 3.60, 1.12ppm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap