Mechanical pipe jacking construction process

A construction technique and pipe jacking technology, which is applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc., can solve problems such as large dependence on operators, high professional requirements of operators, and impact on construction quality, etc., to achieve Avoid the effect of jacking difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

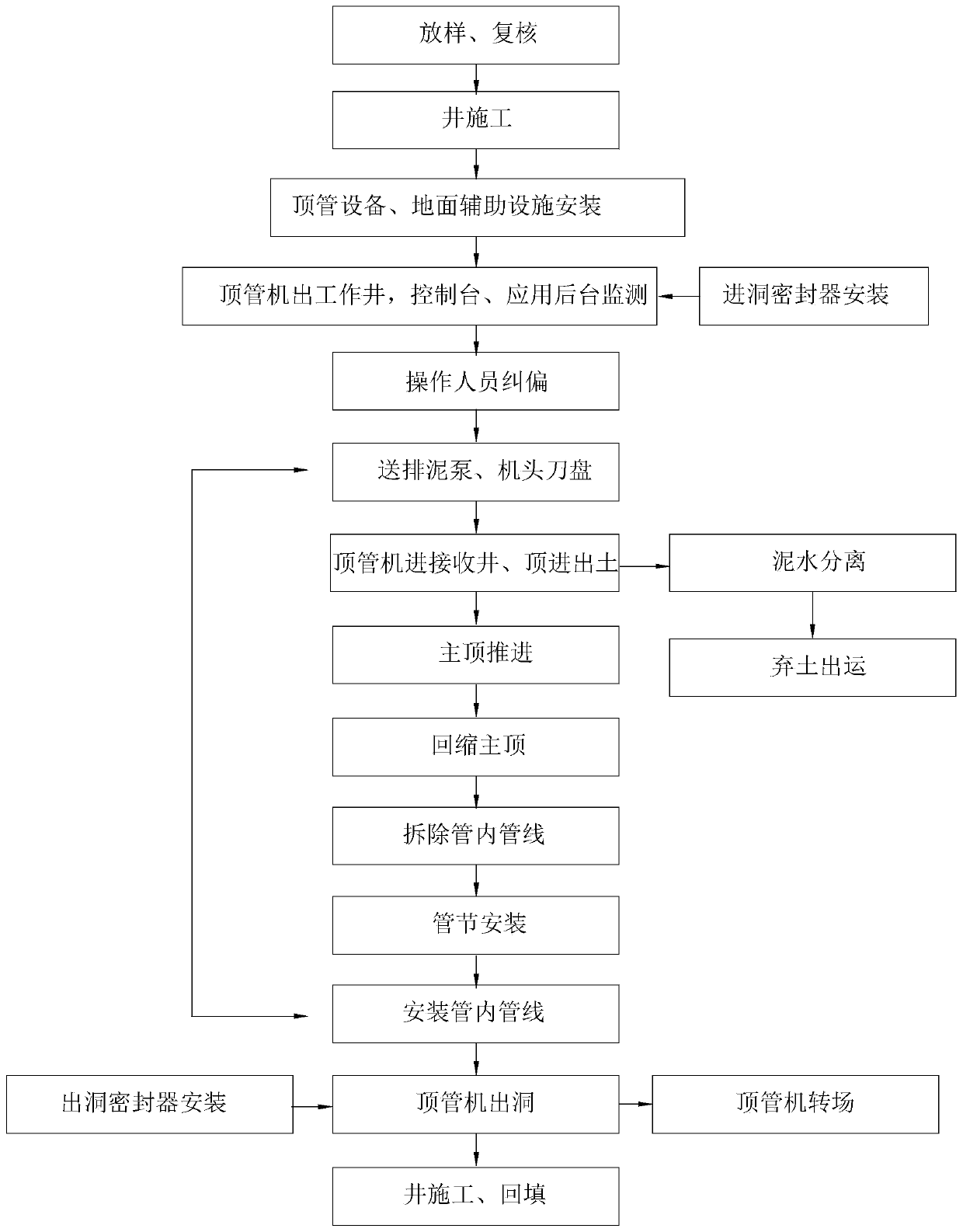

[0048] refer to figure 1 , is the mechanical pipe jacking construction technique disclosed by the present invention, comprising the following steps:

[0049] Stakeout review: measure the lead point at the construction location, stake out, and perform position review to determine the well location.

[0050] Well construction: setting up light well points, excavating foundation pits with backhoes, constructing sand cushions and plain concrete cushions, making caissons in sections, sinking in stages, draining and digging, and sealing the bottom of caissons and floor pouring to complete the excavation of the working well and the receiving well.

[0051] Immediately after the foundation pit is formed, backfill and tamp it with coarse sand layer by layer, supplemented by watering, and compact it with a plate vibrator or frog ram to ensure the bearing capacity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com