Shape memory alloy eccentric locking device and mounting method thereof

A memory alloy and eccentric locking technology, which is applied in the field of nut locking, can solve problems such as difficult to meet the anti-loosening requirements, inability to disassemble, poor seismic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

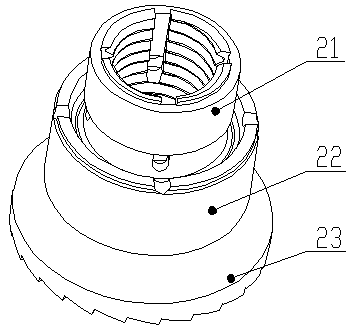

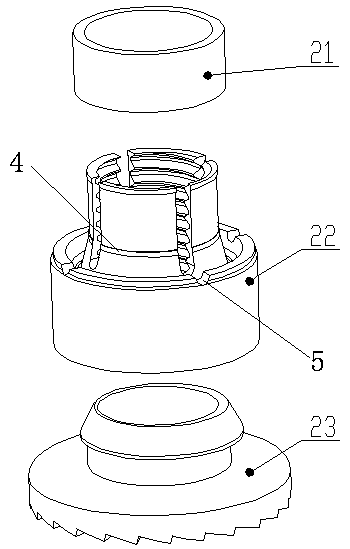

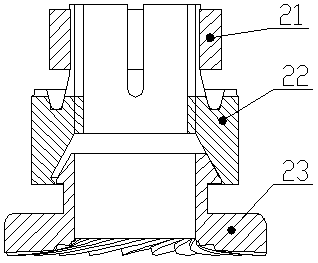

[0023] Such as Figure 1-Figure 4 As shown, a shape memory alloy eccentric locking device includes a bolt 1, a connecting piece 31 and a connected piece 32. The bolt 1 passes through the through holes of the connected piece 32 and the connecting piece 31 in sequence and is connected to the locking mechanism. The tightening mechanism includes a memory alloy fastening ring 21, a slotted nut 22 and a locking washer 23, the locking washer 23 is set on the bolt 1, the bottom of the locking washer 23 is in contact with the surface of the connector 31, and the upper part of the locking washer 23 is a cone Shaped eccentric connector, conical eccentric connector and the bottom of the slotted nut 22 are installed together, the upper part of the slotted nut 22 is annularly distributed with a number of internal thread petals, the internal thread petals are matched with a memory alloy fastening ring 21, and the inner side of the bottom of the slotted nut 22 It is a tapered structure, and t...

Embodiment 2

[0026] Such as Figure 1-Figure 4 As shown, a shape memory alloy eccentric locking device includes a bolt 1, a connecting piece 31 and a connected piece 32. The bolt 1 passes through the through holes of the connected piece 32 and the connecting piece 31 in sequence and is connected to the locking mechanism. The tightening mechanism includes a memory alloy fastening ring 21, a slotted nut 22 and a locking washer 23, the locking washer 23 is set on the bolt 1, the bottom of the locking washer 23 is in contact with the surface of the connecting piece 31, and the upper part of the locking washer 23 is a cone Shaped eccentric connector, conical eccentric connector and the bottom of the slotted nut 22 are installed together, the upper part of the slotted nut 22 is annularly distributed with a number of internal thread petals, the internal thread petals are matched with a memory alloy fastening ring 21, and the inner side of the bottom of the slotted nut 22 It is a tapered structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com