Emergency industrial steam supply system for realizing shutdown of large coal-fired generator set without boiler stopping

A technology of non-stop boiler and generator set, which is applied to steam superheating, steam generation, steam generation devices, etc., and can solve problems such as heat supply stop, steam supply stop, and heat supply not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

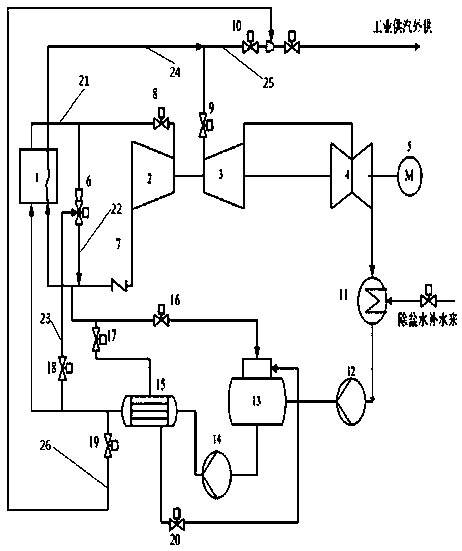

[0014] Such as figure 1 As shown, the embodiment of the present invention provides an emergency industrial steam supply system that realizes shutdown of large-scale coal-fired generating units without stopping the furnace, including a boiler 1, a high-pressure cylinder 2, a medium-pressure cylinder 3, a low-pressure cylinder 4, a generator 5, a high-pressure Cylinder steam inlet valve group 8, high discharge check valve 7, medium pressure cylinder steam inlet valve group 9, condenser 11, condensate pump 12, deaerator 13, electric feed water pump 14, No. 2 high pressure heater 15 and several A valve group 16, 17, 20, the above structure is the existing structure, and a bypass steam supply system is added on the basis of the existing structure, specifically: a high-pressure bypass is added at the main steam outlet pipe 21 of the boiler 1 Pipe 22, the steam outlet end of the high-pressure bypass pipe 22 merges with the exhaust steam of the high-pressure cylinder 2, and is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com