Light guide film, production method thereof and light guide device

A technology of light guide film and production process, which is applied in the direction of light guide, optics, optical components, etc., which can solve the problems of unfavorable long-term use and easy detachment, and achieve the effect of strong damage resistance, strong stretch resistance, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

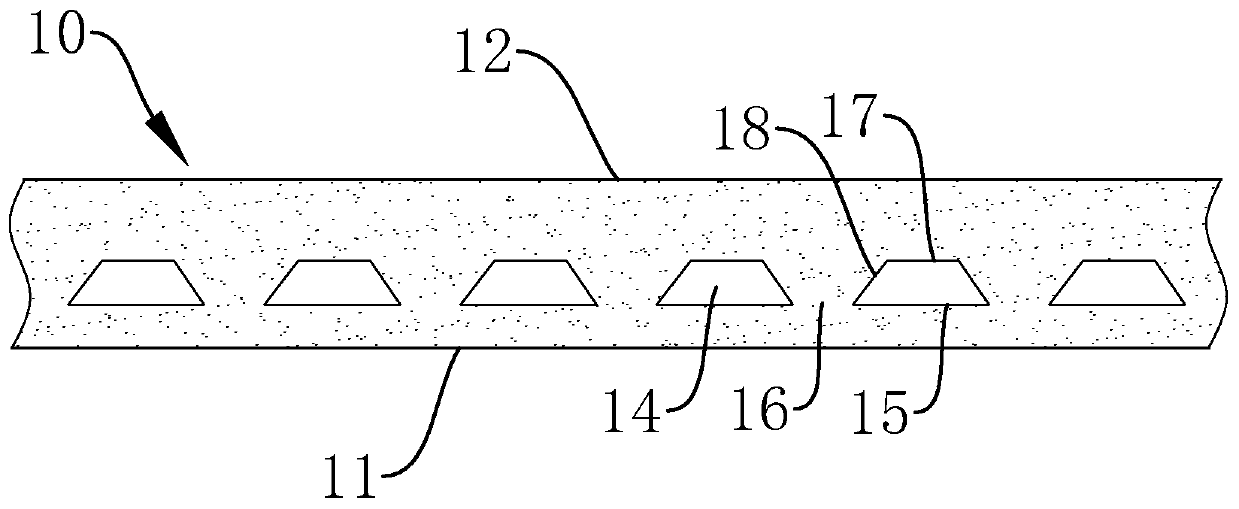

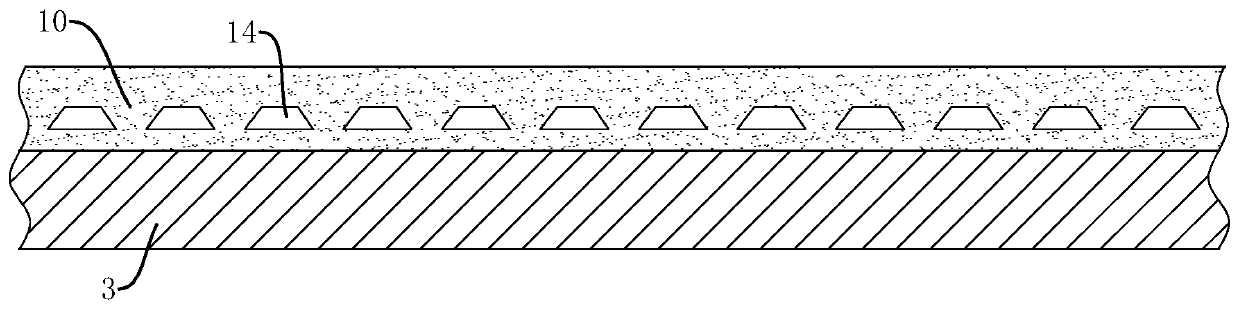

[0053] see figure 1 , a light guiding film 10, the upper surface of the light guiding film 10 is a light exit surface 12, and the lower surface is a light incident surface 11; the lower surface of the light guiding film 10 is smoothly arranged, and is used for fixed connection with the substrate 3 ( see figure 2 ); said light guiding film 10 is provided with several hollow ultramicrostructures 14, the side of said hollow ultramicrostructures 14 close to the lower surface of light guiding film 10 is a conducting and reflecting surface 15, every two adjacent ultramicrostructures The gaps between structures 14 are light exit gaps 16 .

[0054] In this embodiment, the lower surface of the light guide film 10 is set to be smooth, so that when it is fixed with the substrate 3, the entire surface can be bonded, the contact area can be maximized, and the fixing effect can be optimal, and the two are not easy to separate.

[0055] In this embodiment, the hollow ultramicrostructure 1...

Embodiment 2

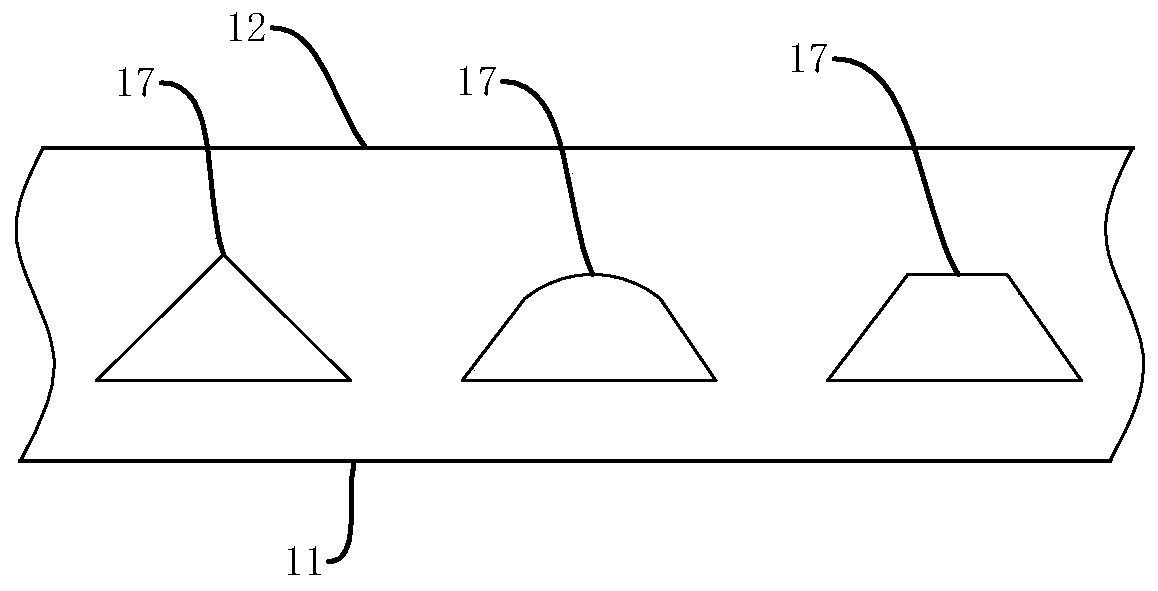

[0070] The difference between this embodiment and Embodiment 1 is that in this embodiment, the light-emitting reflection surface 18 is an arc-shaped surface.

[0071] Such as Figure 8 Shown is the light emitting line in Embodiment 1 when the light emitting reflective surface 18 is a slope. When the light hits the inclined surface, it is reflected and directed to the light emitting surface 12. Since the angles of the light directed to the inclined surface are different, the angles of the light emitted to the light emitting surface 12 after reflection are also different, and the intensity of the emitted light will be different.

[0072] In this example, if Figure 9 As shown, the light-emitting reflective surface 18 is set as an arc-shaped surface. When the light-emitting reflective surface is a curved surface, the angle between the tangent surface at any point on the curved surface and the light-incident surface is 45°-85°. By designing the angle of the arc surface, after th...

Embodiment 3

[0075] This embodiment provides a production process for a hollow ultra-microstructured light-guiding film, which is used to produce the light-guiding film of Example 1, and its production steps are as follows:

[0076] 1) Select the raw material, the raw material of the light guide film is optical grade transparent silica gel;

[0077] 2) Select a mold that is consistent with the shape of the light guide film (with an ultra-structure core mold);

[0078] 3) Inject the silicone raw material into the mold and shape it through the silicone molding process.

[0079] The integrally formed light guide film has a simpler process, and the hollow ultra-microstructure is set inside the light guide film. While guiding light, it is not easy to damage itself and has stronger tensile resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com