Multi-mode dustproof heat dissipation case

A multi-mode, dust-proof technology, applied in the computer field, can solve the problems of dust-proof and heat dissipation of the chassis, and achieve dust-proof and heat-dissipation firmness, cleanliness, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

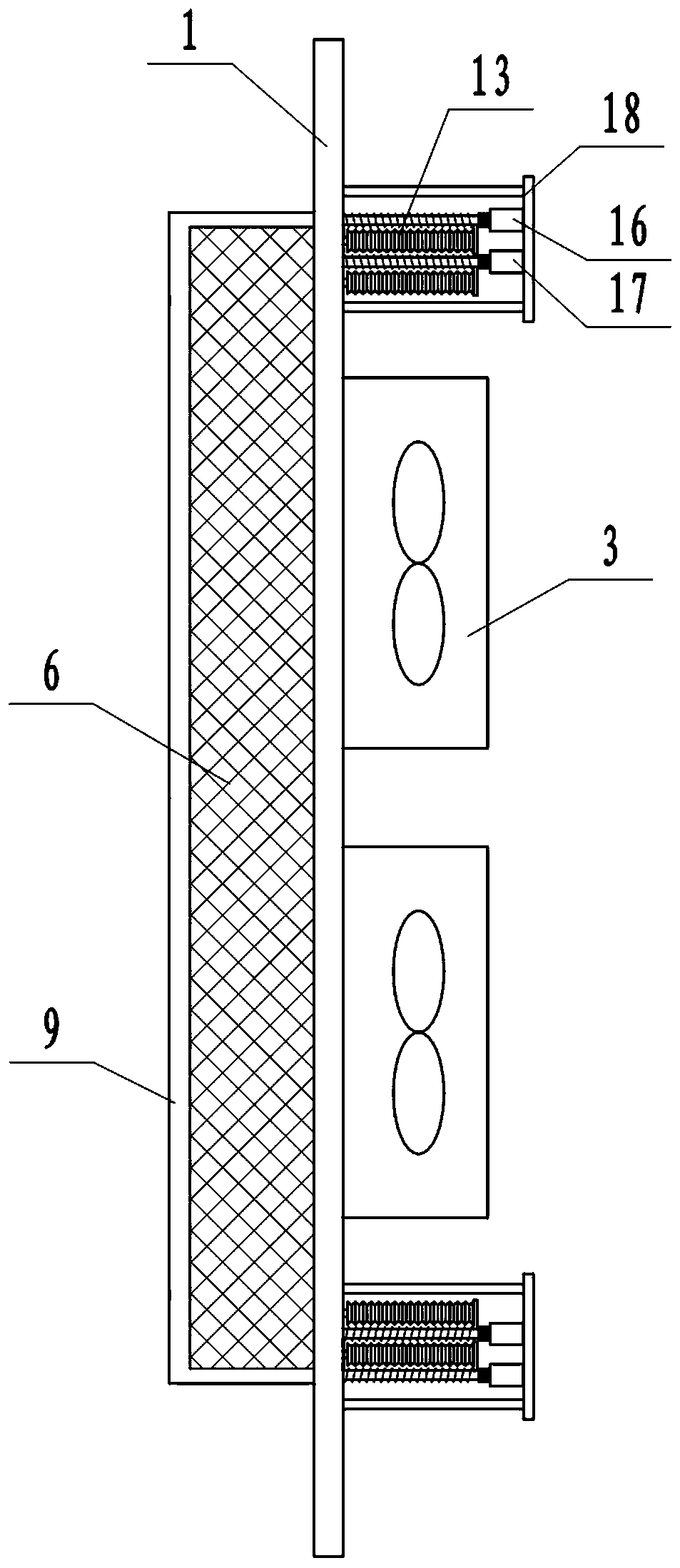

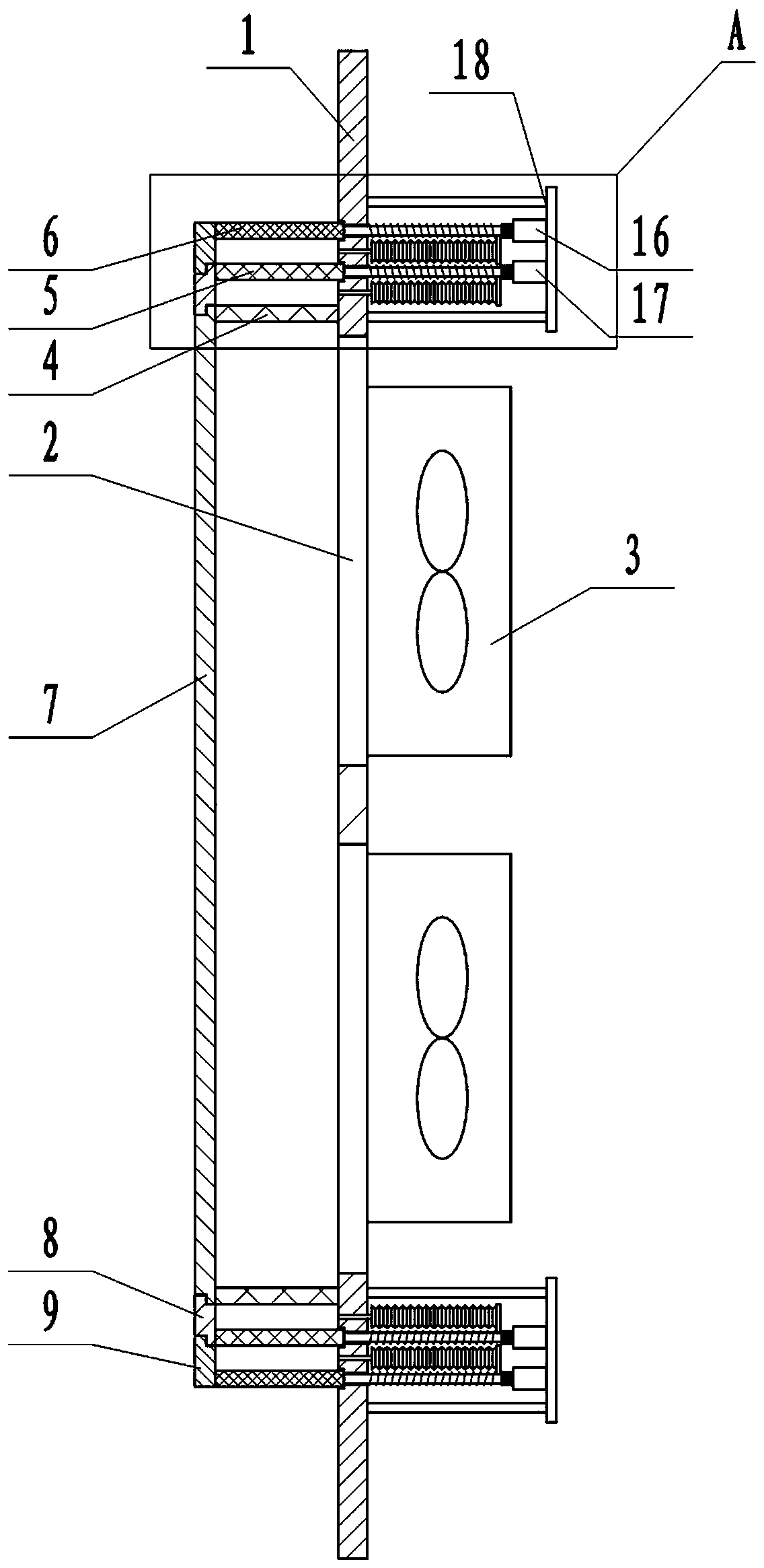

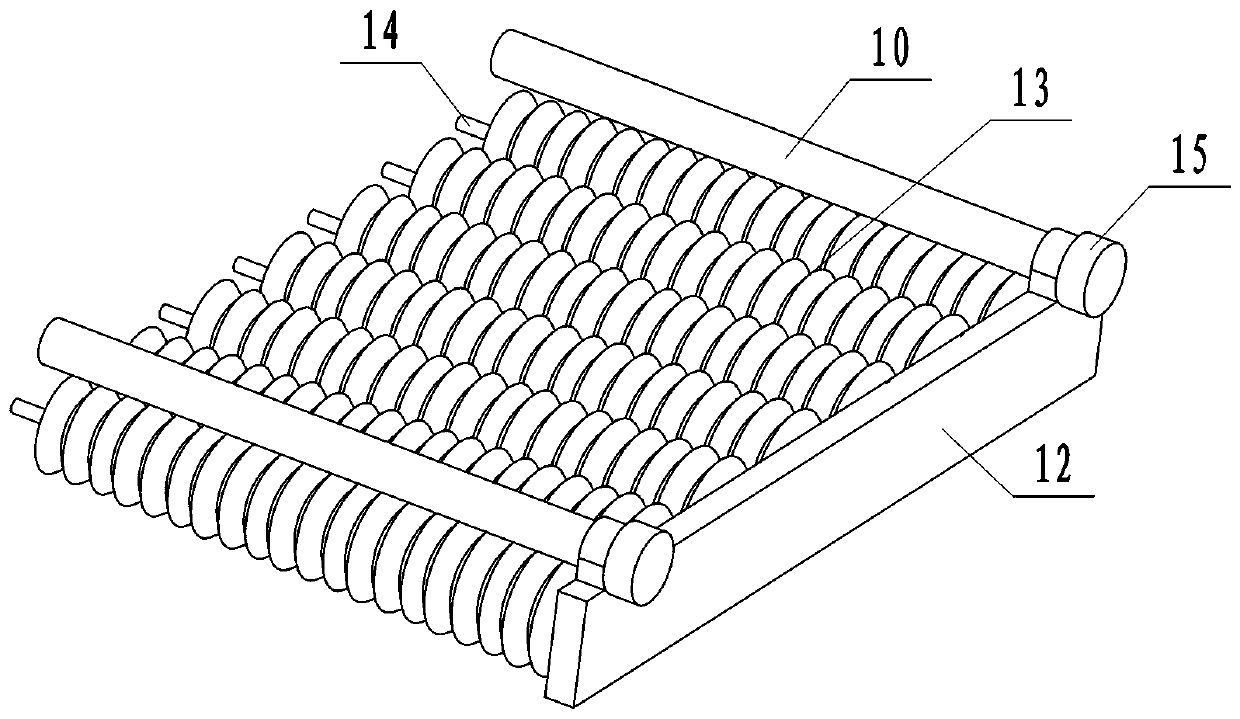

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Depend on Figure 1 to Figure 7 Given, the present invention comprises a box plate 1, and two through holes 2 are provided on the box plate 1, and a fan 3 is installed in the through holes 2; Net 4, the outside of the first filter screen 4 is equipped with the second filter screen 5 that can move left and right, and the outside of the second filter screen 5 is equipped with the third filter screen 6 that can move left and right; the first filter screen 4, the second filter screen The number of meshes of the net 5 and the third filter screen 6 increases successively; the three filter screens are composed of four faces, the front, the rear, the top, and the bottom; The left side is fixed with a second baffle 8 that can be tenoned with the first baffle 7; the left side of the third filter screen 6 is fixed with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com