A Method for Adjusting Beam Divergence Angle of Vertical Cavity Surface Emitting Semiconductor Laser

A technology of vertical cavity surface emission and beam divergence angle, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of current density affecting the reliability of VCSELs, light-emitting area limiting the maximum output power of VCSELs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

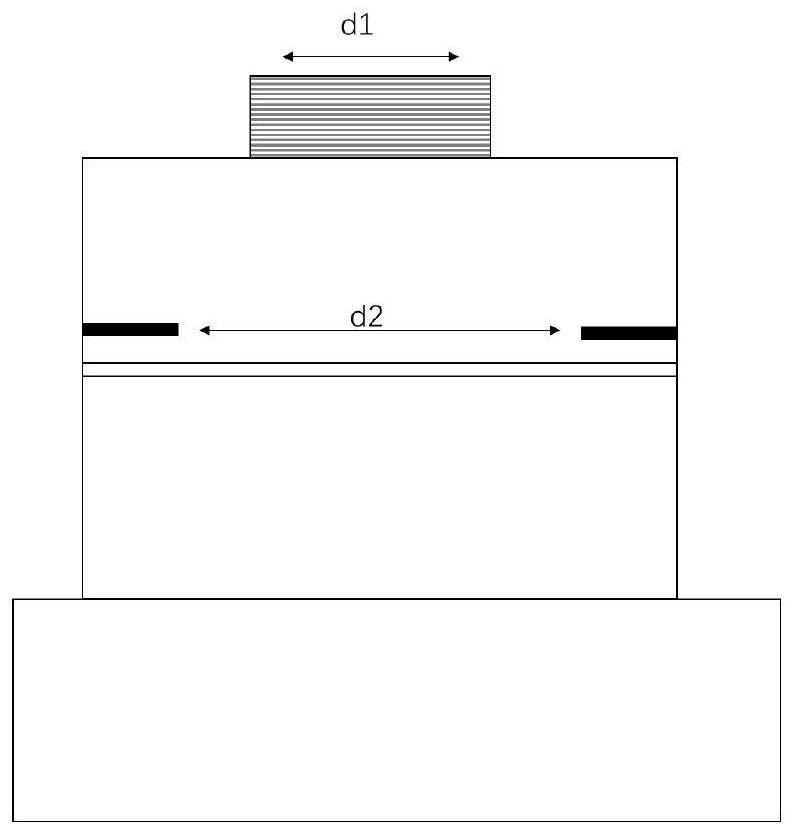

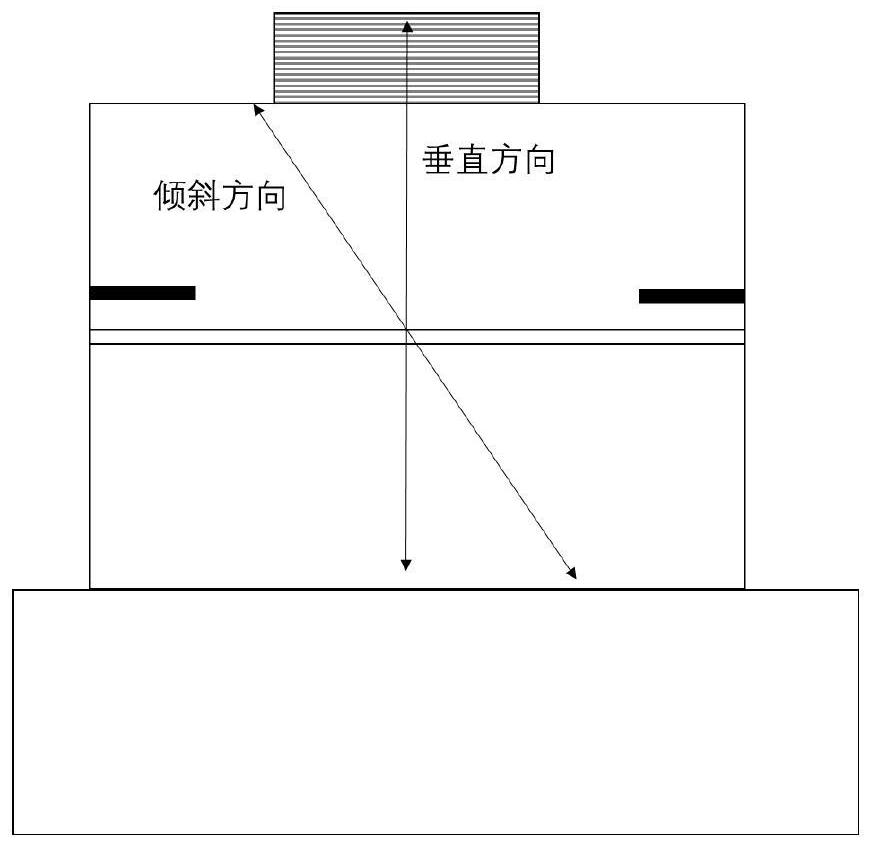

[0016] A method for adjusting the beam divergence angle of a vertical cavity surface-emitting semiconductor laser, using epitaxial technology to sequentially grow an N-type semiconductor reflective layer, an active layer, and a P-type semiconductor reflective layer on a semiconductor substrate; the N-type semiconductor reflective layer and the P The type semiconductor reflection layer is a plurality of pairs of distributed Bragg mirror layers composed of two semiconductor materials with different refractive indices;

[0017] The P-type semiconductor DBR has a reduced logarithm;

[0018] A certain logarithm of the dielectric DBR layer is fabricated on the P-type semicond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com