Arc-shaped black gate light-resistant curtain for laser television and manufacturing method

A technology of laser TV and production method, which is applied to color TV, color TV parts, optics, etc., can solve the problems of complex black grid anti-light curtain production process, high difficulty, low efficiency, etc., and achieve good display effect and low cost. Low, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

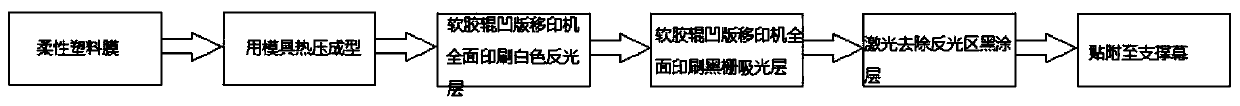

[0040] combine figure 2 and image 3 Shown, a kind of manufacturing method of arc-shaped black grating anti-light curtain for laser TV, comprises the following steps:

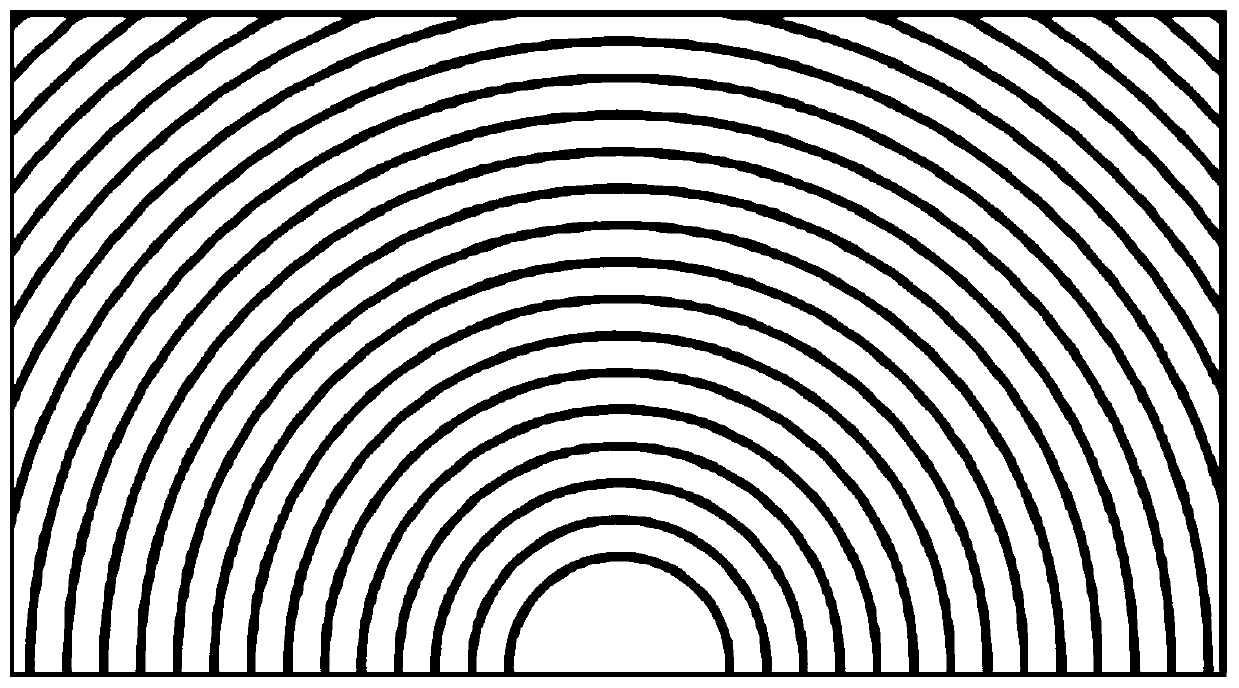

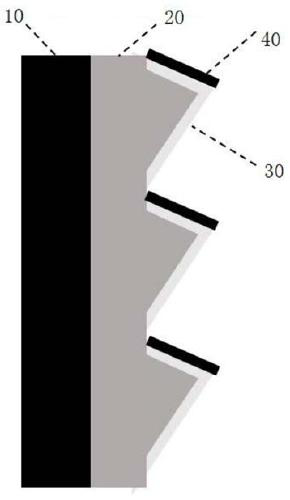

[0041] S1. Using UV resin or thermoplastic material as the substrate layer, using mold hot pressing to form a prism structure array with curved surface distribution;

[0042] S2. Use gravure printing equipment to print a white reflective layer on both the light-absorbing surface and the reflective surface of the prism structure;

[0043] S3. Use gravure pad printing equipment to print black light-absorbing coating on both the light-absorbing and reflective surfaces of the prism structure;

[0044] S4, using a laser to remove the black light-absorbing coating on the reflective surface;

[0045] S5. Attach the printed curtain to the supporting curtain.

[0046] Preferably, the substrate layer in step S1 is a plastic film or PET.

[0047] In the above technical solution, the black light-absorbing coating or ...

Embodiment 2

[0050] A method for manufacturing an arc-shaped black grid anti-light curtain for laser television, comprising the following steps:

[0051] S1. White plastic film is used as the base material layer, and molded by hot pressing to form a prism structure array with curved surface distribution;

[0052] S2. Use gravure pad printing equipment to print black light-absorbing coating on both the light-absorbing and reflective surfaces of the prism structure;

[0053] S3, using a laser to remove the black light-absorbing coating on the reflective surface;

[0054] S4. Attach the printed curtain to the supporting curtain.

[0055] In the above technical solution, the substrate layer in step S1 is a white plastic film. Compared with Example 1, there is no need to print a white reflective layer on the prism structure, and the white color of the white plastic film itself can achieve a reflective effect instead of white Reflective layer.

[0056] The gravure pad printing equipment used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com