Compliance control system for puncture surgical robot

A surgical robot and compliant control technology, applied in surgical manipulators, surgical robots, puncture needles, etc., can solve problems that cannot meet the requirements of difficult operations, and achieve the effects of reducing algorithm complexity, strong practicability, and improving real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0026] The problem to be solved by the present invention is to provide a compliance control system for a puncture surgery robot with high working precision, stable working and high efficiency.

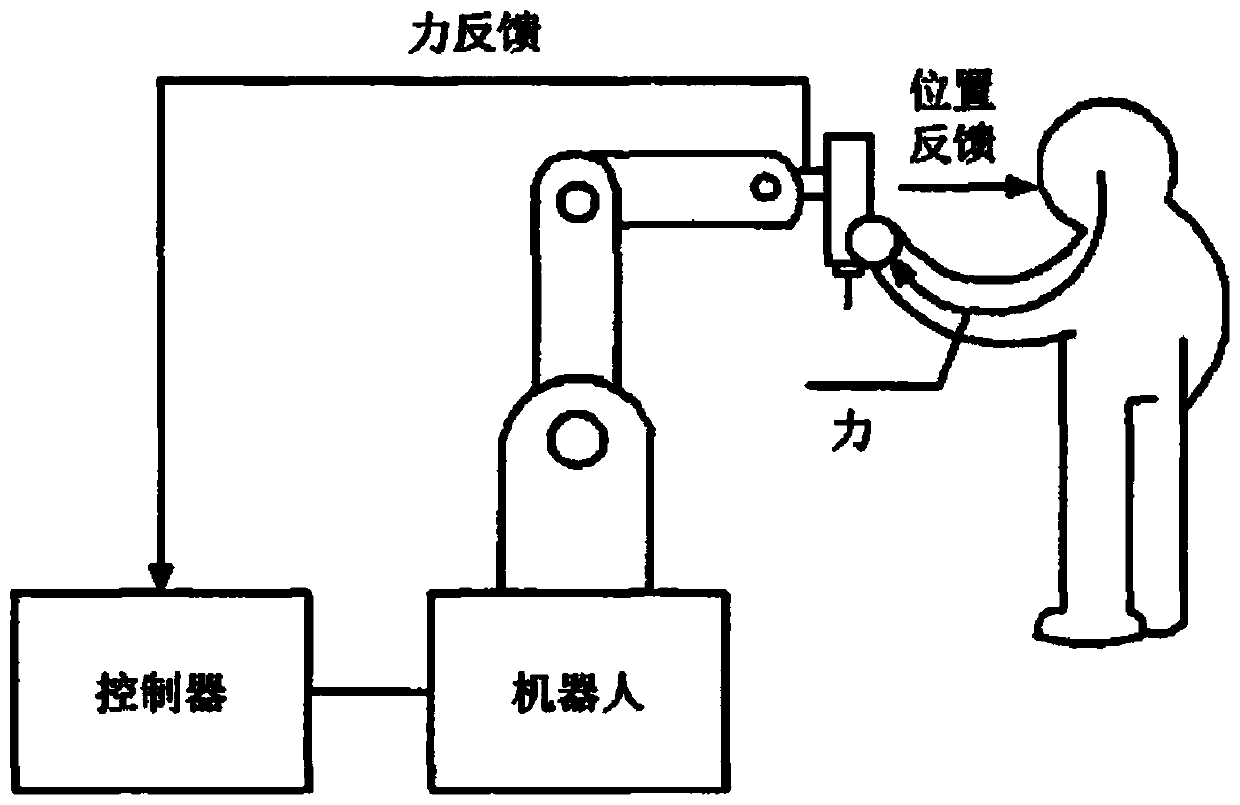

[0027] Such as figure 1 As shown, in order to solve the above problems, the present invention provides a puncture surgery robot compliance control system device, including:

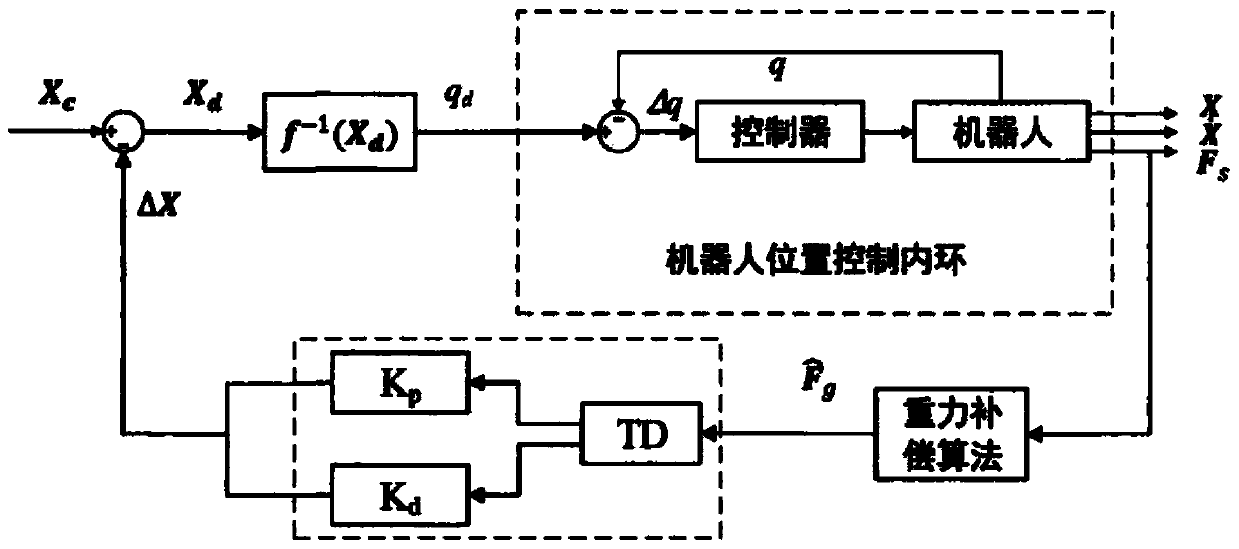

[0028] Differential controller-based PD control module for suppressing measurement noise and tracking the original signal;

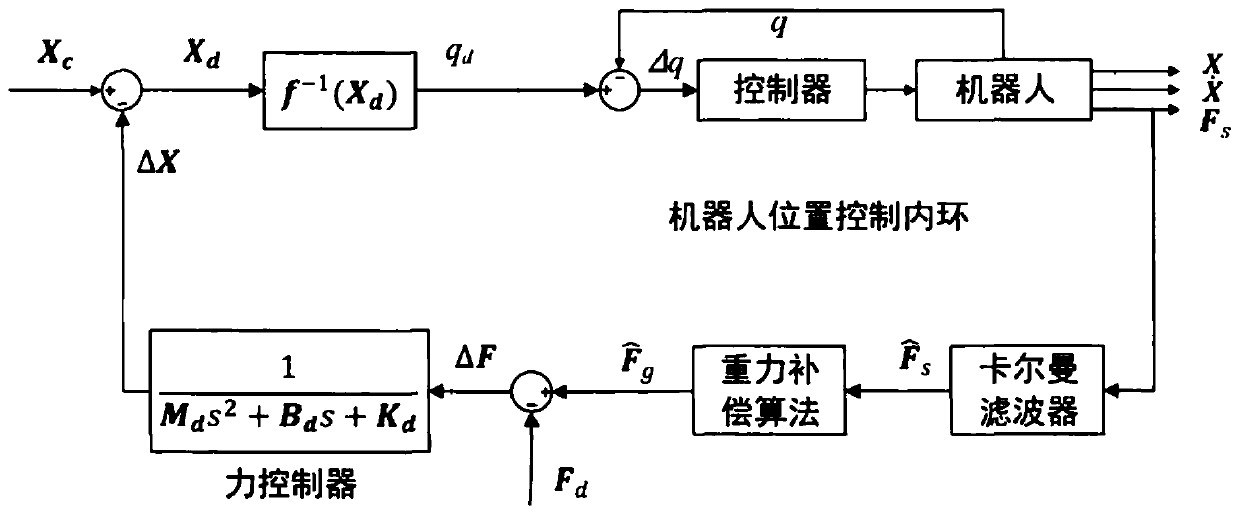

[0029] Impedance control position model building module, used to establish a dynamic motion model of the robot control cycle;

[0030] The force feedback control module follows the operator to achieve zero-force following control, that is, the resultant external force on the joints of the manipulator is 0.

[0031] The beneficial effect of the present invention is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com