Concentration device capable of realizing automatic rotary defoaming and application thereof

A concentrating device, automatic rotation technology, applied in the direction of feeding device, chemical/physical/physical-chemical process, chemical instrument and method, etc., can solve problems affecting the normal operation of concentrating device, decomposition of effective components of compounds, collector ring water intake, etc. problems, to achieve the effect of increasing the unit capacity of the equipment, increasing the molecular motion, and increasing the molecular collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

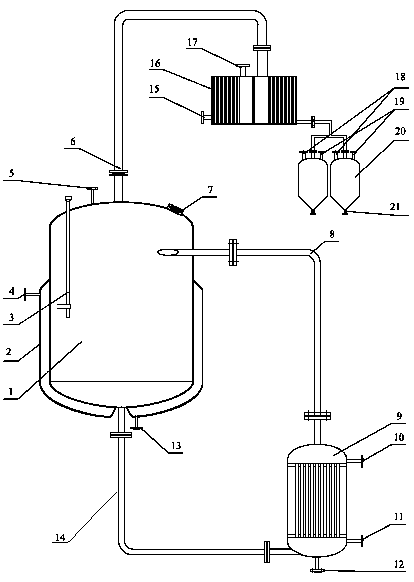

[0021] Such as figure 1 As shown, the automatic rotary defoaming and concentrating device of the present invention includes a reactor 1 and a heater 9; the top of the reactor 1 is connected to the top of the heater 9 through a material conduit A8, and the bottom of the reactor 1 is passed through a material The conduit B14 communicates with the bottom of the heater 9 to form a circulating heating system; the shell of the reaction kettle 1 is provided with a jacket 2, the upper end of the jacket 2 is provided with a steam inlet A4, and the upper end of the heater 9 is provided with a steam inlet B10, The bottom of the reactor 1 is provided with a coolant outlet A, and the bottom of the heater 9 is provided with a coolant outlet B13; the top of the reactor 1 is also provided with a material inlet 5, a thermometer 3 and a sight glass 7; The bottom of the heater 9 is provided with a discharge port A12; the top of the heater 9 is level with the bottom of the reaction kettle 1 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com