Cleaning device and cleaning method

A cleaning device and electrostatic precipitator technology, which is applied to cleaning methods and utensils, electrostatic cleaning, chemical instruments and methods, etc., can solve the problems of inability to clean particles, low cleaning efficiency, waste of resources, etc., and improve the convenience of operation. , The effect of high cleaning efficiency and short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

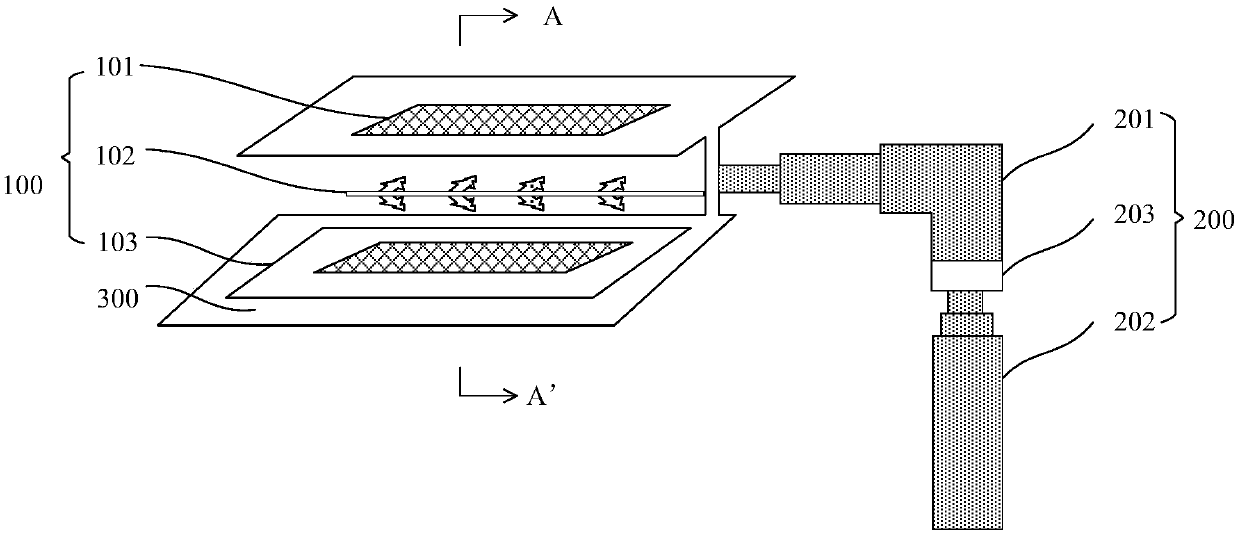

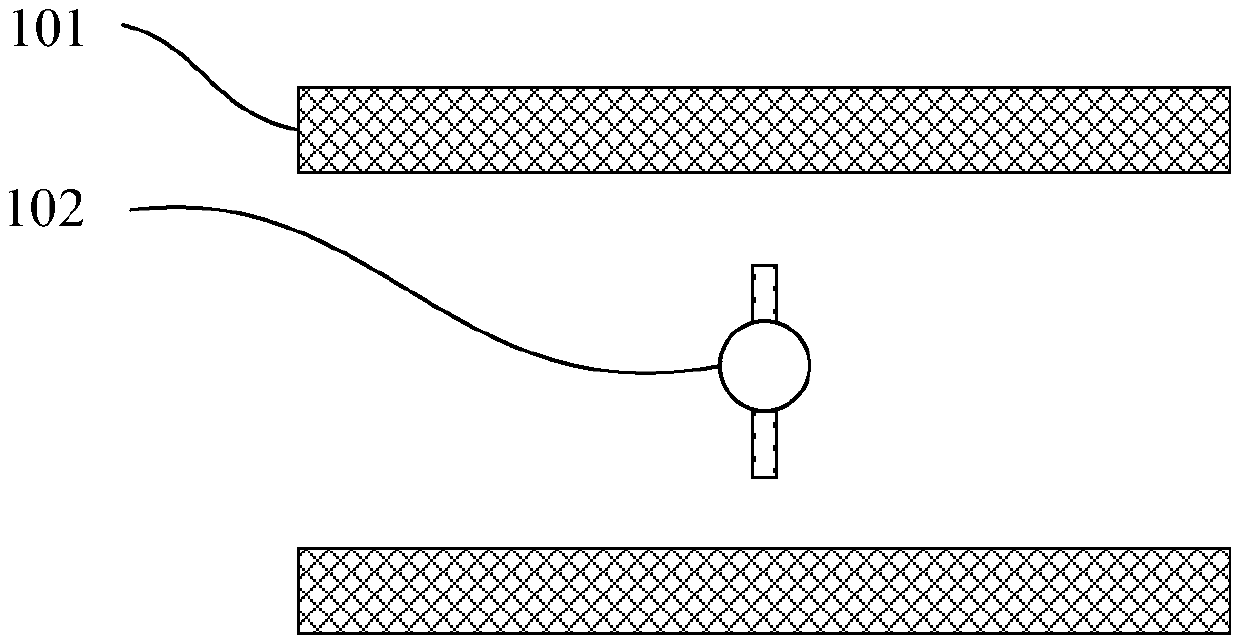

[0042] Such as Figure 1 ~ Figure 2 , the present embodiment provides a cleaning device, the cleaning device includes: an electrostatic precipitator 100 and a driving part 200; the electrostatic precipitator 100 includes a dust collecting electrode 101 and a corona electrode 102; Telescopic units 201, 202 and a rotating unit 203; the telescopic unit 201 is connected with the electrostatic precipitator 100, and the displacement of the electrostatic precipitator 100 is controlled by the telescopic units 201, 202; the rotating unit 203 and The telescopic units 201 and 202 are connected and located between the telescopic units 201 and 202 , and the direction of the telescopic unit 201 is controlled by the rotating unit 203 .

[0043] In this embodiment, the position of the electrostatic precipitator 100 is adjusted through the driving part 200 in the cleaning device, and the convenience of operation is improved; the electrostatic precipitator is used for electrostatic dust removal...

Embodiment 2

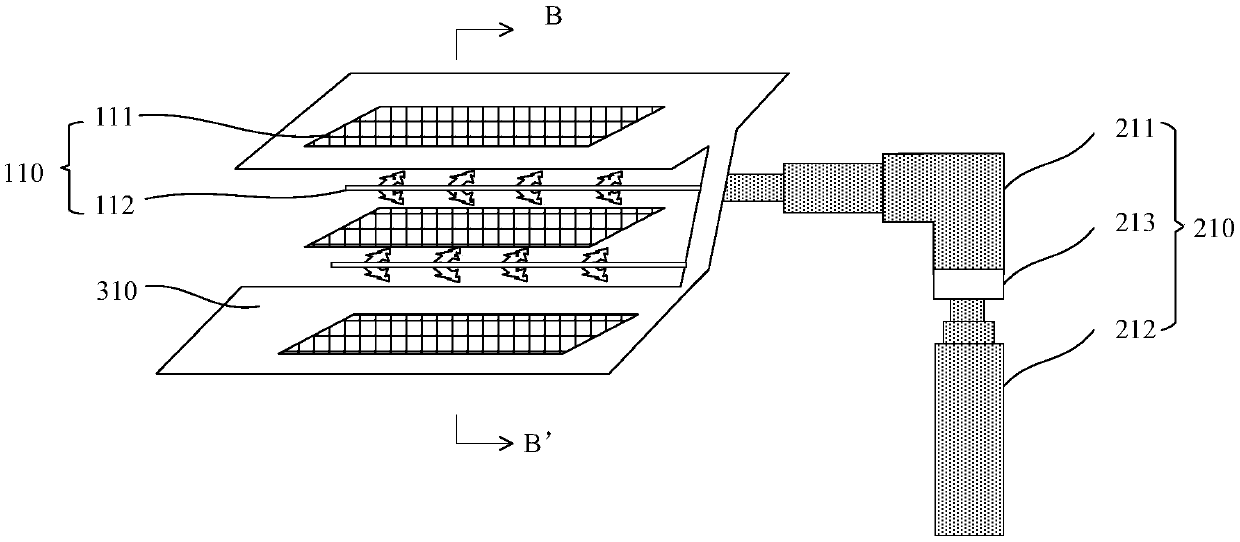

[0062] Such as Figure 3 ~ Figure 4 This embodiment provides a cleaning device, which has a different structural appearance from that of Embodiment 1, so that those skilled in the art can further understand the cleaning device in the present invention. The cleaning device includes: an electrostatic precipitator 110 and a driving part 210; the electrostatic precipitator 110 includes a dust collecting pole 111 and a corona pole 112; the driving part 210 includes two telescopic units 211, 212 and a rotating unit 213 The telescopic unit 211 is connected to the electrostatic precipitator 110, and the displacement of the electrostatic precipitator 110 is controlled by the telescopic unit 211, 212; the rotating unit 213 is connected to the telescopic unit 211, 212, Located between the telescopic units 211 and 212 , the direction of the telescopic unit 211 is controlled by the rotation unit 213 .

[0063] In this embodiment, the position of the electrostatic precipitator 110 is adjus...

Embodiment 3

[0073] Such as Figure 5 , the present invention also provides a cleaning method, comprising the following steps:

[0074] S1: providing the above-mentioned cleaning device, and placing the electrostatic precipitator in the cleaning device in an idle position;

[0075] S2: adjust the position of the electrostatic precipitator through the driving part in the cleaning device, so that the electrostatic precipitator is in a working position;

[0076] S3: cleaning by the electrostatic precipitator;

[0077] S4: Restore the electrostatic precipitator to the idle position through the driving component.

[0078] The present invention adjusts the position of the electrostatic precipitator through the driving parts in the cleaning device to improve the convenience of operation; through the electrostatic precipitator, the electrostatic precipitator is used; the cleaning time is short, the cleaning efficiency is high, the cleaning effect is good, and the cleaning process does not introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com