Cold-rolling mathematical model-based power consumption prediction method for combined pickling-cold rolling unit

A combined unit and power consumption technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of power consumption prediction, only consider the power consumption of rolling mills, and the model does not carry out self-learning, so as to save production costs , reduce the intermediate error, and ensure the effect of calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0061] The invention provides a method for predicting electric energy consumption of a combined acid-rolling unit based on a cold-rolling mathematical model.

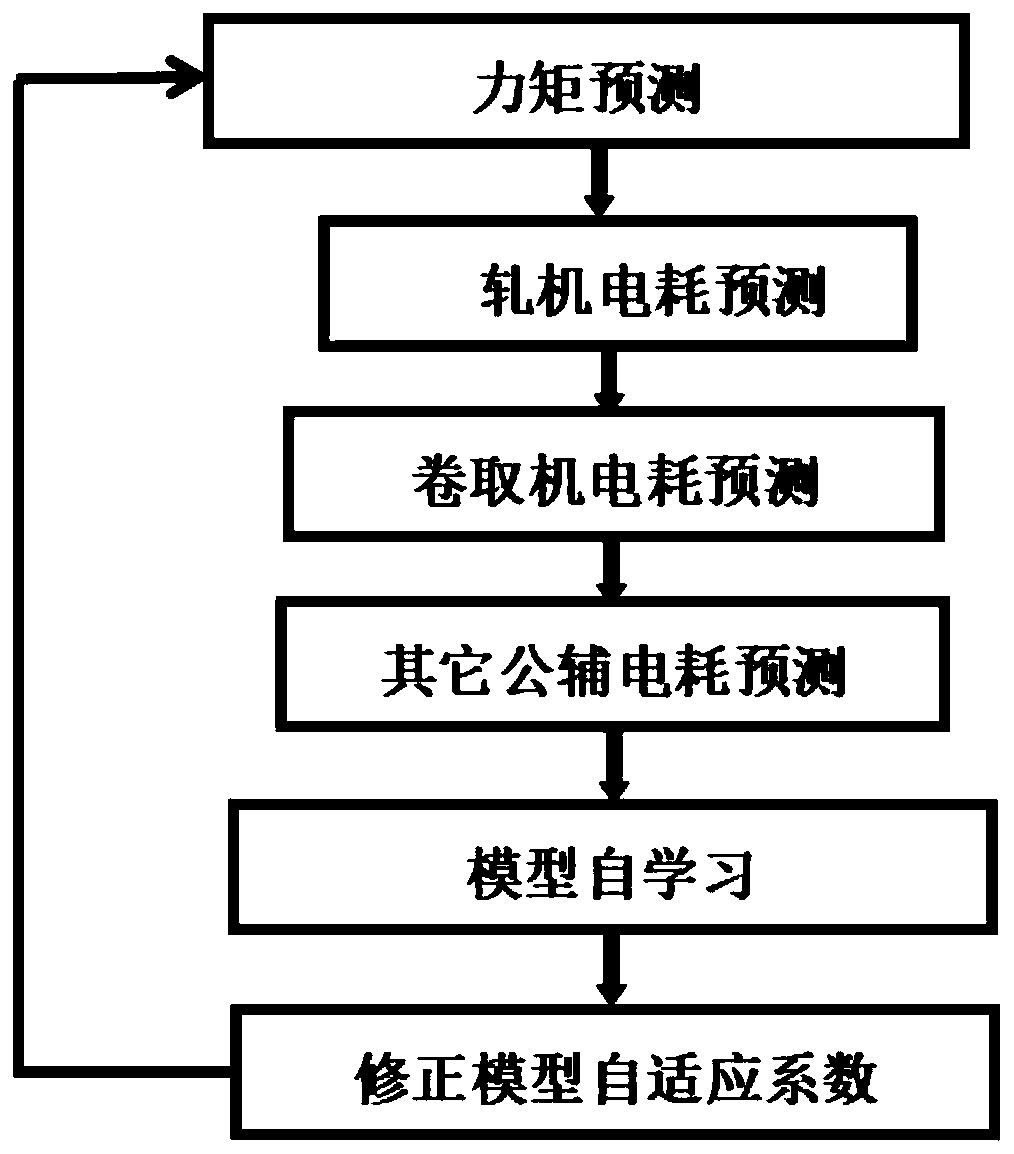

[0062] Such as figure 1 As shown, the method includes the following steps:

[0063] (1) Moment prediction: After the rolling plan is issued, calculate the rolling moment, tension moment, and loss moment of each stand according to the raw material specifications and finished product specification parameters of the strip;

[0064] (2) Prediction of rolling mill power consumption: calculate the required power consumption of each stand according to the rolling torque, tension torque and loss torque calculated in step (1);

[0065] (3) Prediction of power consumption of the coiler: calculate the powe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap