Concrete curing chamber with good curing effect

A curing room and concrete technology, which is applied in the field of concrete curing room, can solve the problems of water vapor and water droplets infiltration, insufficient temperature transfer, and inability to fully and evenly cover concrete specimens, etc., and achieves good curing humidity conditions, good curing temperature conditions, Guaranteed maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] This example:

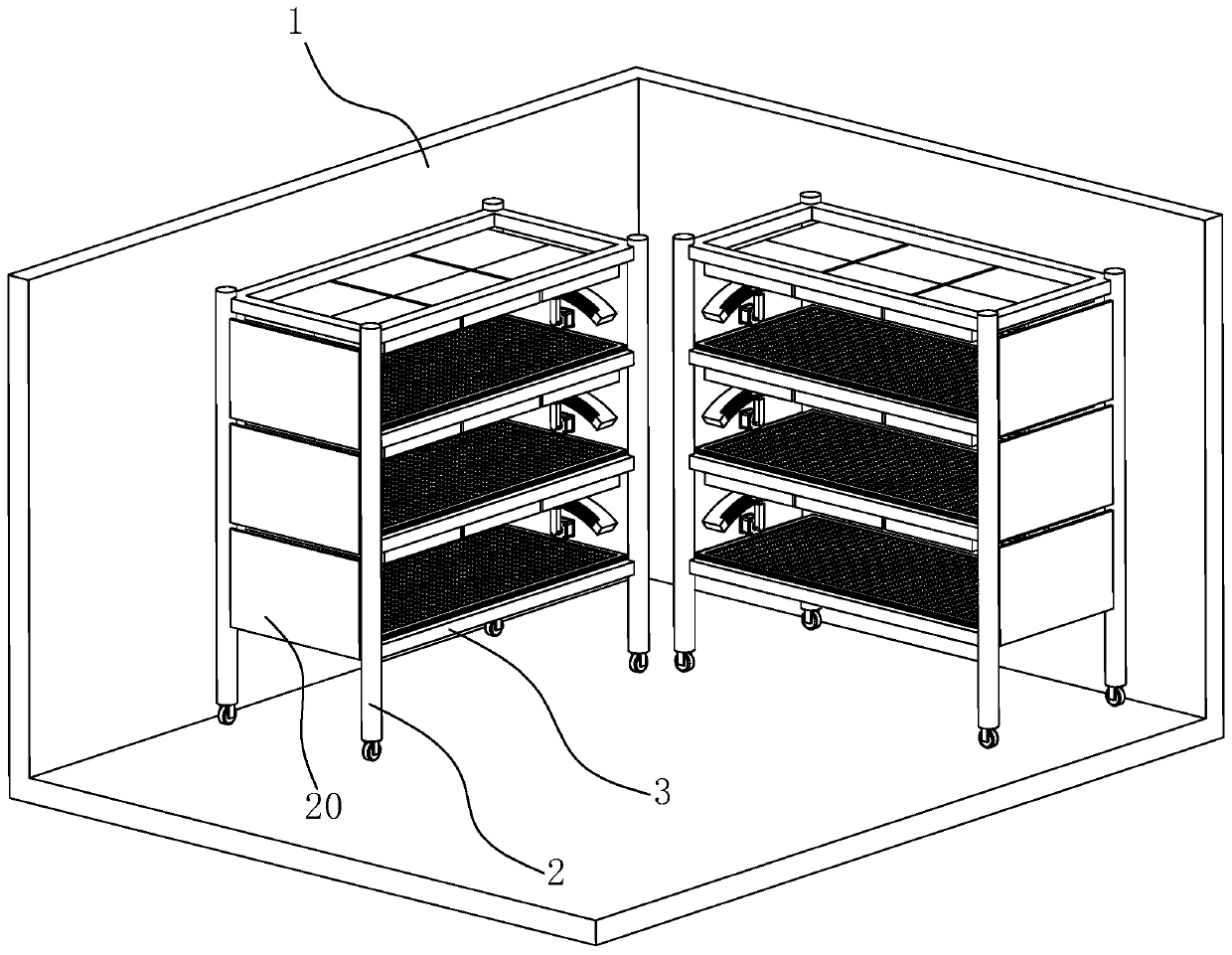

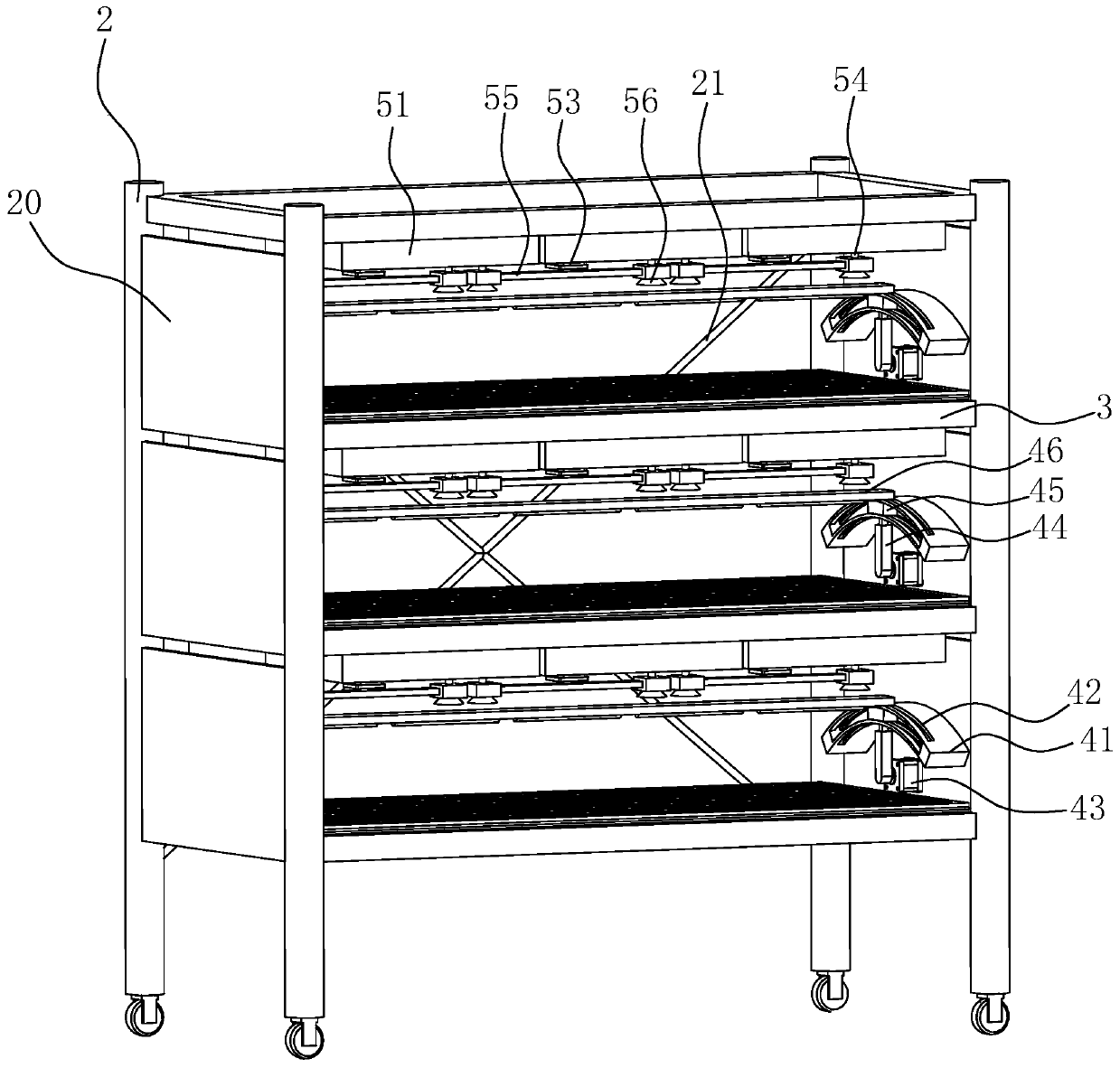

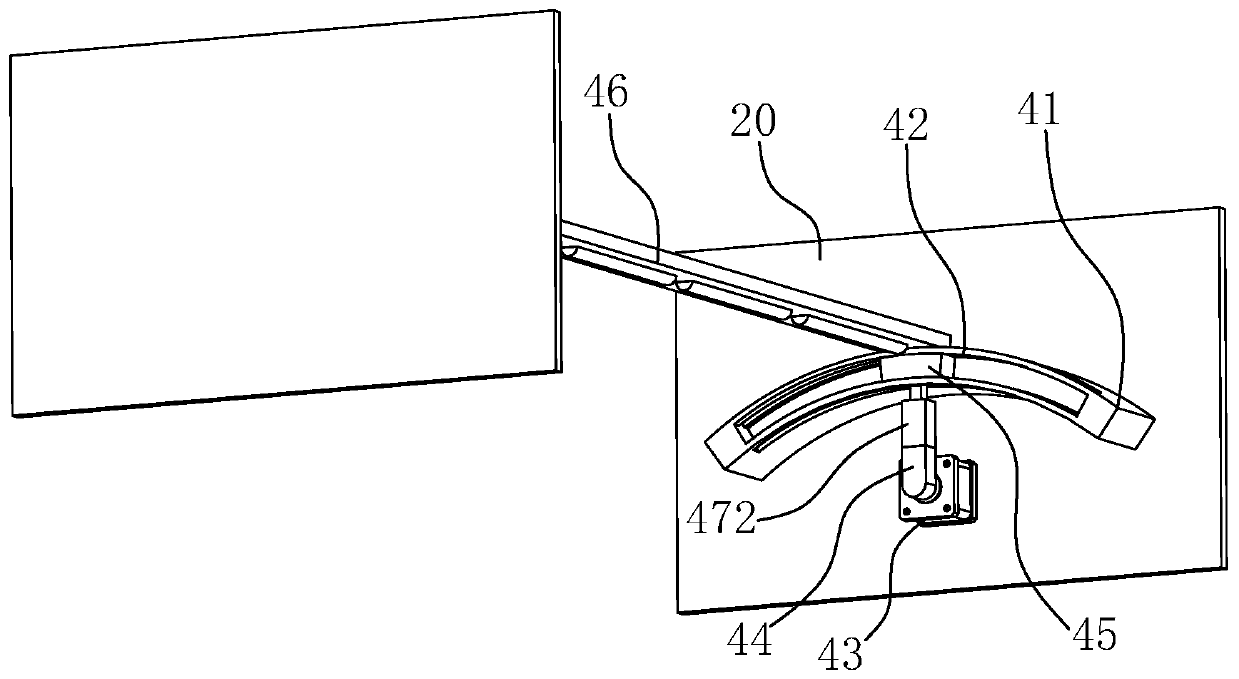

[0041] A concrete curing room with better curing effect, such as figure 1 , figure 2 As shown, it includes a placement rack 2, a placement layer 3, an air-conditioning cooling system, a temperature control component and a humidity control component.

[0042] The air-conditioning cooling system is installed in the curing room 1. The air-conditioning cooling system is an inverter air-conditioning system. The curing room 1 is provided with an air exhaust port, and the air exhaust port is arranged around the ceiling and the skirting line of the ground in the curing room 1. The air exhaust port is connected to the air outlet of the frequency conversion air conditioning system, and the temperature in the curing room 1 can be regulated through the frequency conversion air conditioning system, so that the ambient temperature in the curing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com