Thin-film device

A thin-film device and component technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of reduced transparency, increased film manufacturing cost, low resistance, etc., and achieve high light transmittance , Improve stability, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

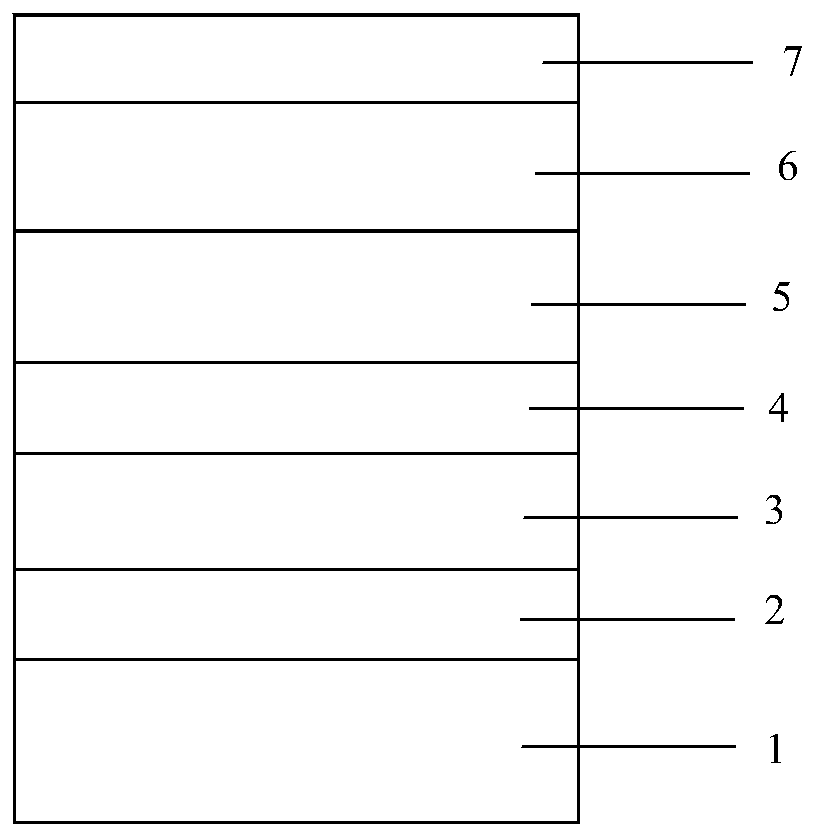

[0049] On the glass substrate 2.0C (substrate 1) is sequentially plated Si with a thickness of 38nm 3 N 4 Film layer; ZnO with a thickness of 8nm 2 Film layer is as dielectric film layer 2; Thickness is the silver film layer 3 of 12nm; Thickness is the GaMg interface film layer 4 of 0.05nm, wherein the content of Ga is 66at%; Thickness is the NiCr film layer (sacrifice film layer 5) of 2nm; ZnSnO with a thickness of 23nm 2 layer (top dielectric layer 6); Si with a thickness of 15nm 3 N 4 The film layer is used as the protective film layer 8 to obtain a heat-treatable coated glass, that is, a thin-film device, with a structure such as figure 1 shown.

[0050] Optical performance test:

[0051] Before heat treatment, the visible light transmittance of a single piece of coated glass is 83.1%; after heat treatment at 580°C for 10 minutes, the visible light transmittance of a single piece of coated glass is 84.3%, and the square resistance is 4.1Ω / □; then washing, assembling,...

Embodiment 2

[0055] On the glass substrate 2.0C (substrate 1), sequentially plate Si with a thickness of 35nm 3 N 4 Film layer; ZnO with a thickness of 10nm 2 Film layer is as dielectric film layer 2; Thickness is the silver film layer 3 of 12nm; Thickness is the GaMg interface film layer 4 of 0.5nm, wherein the content of Ga is 45at%; Thickness is the NiCr film layer (sacrifice film layer 5) of 2nm; ZnSnO with a thickness of 25nm 2 layer (top dielectric layer 6); Si with a thickness of 13nm 3 N 4 The film layer is used as the protective film layer 8 to obtain a heat-treatable coated glass, that is, a thin-film device, with a structure such as figure 1 shown.

[0056] Optical performance test:

[0057] Before heat treatment, the visible light transmittance of a single piece of coated glass is 82.8%; after heat treatment at 580°C for 10 minutes, the visible light transmittance of a single piece of coated glass is 84.1%, and the square resistance is 4.3Ω / □; then washing, assembling, et...

Embodiment 3

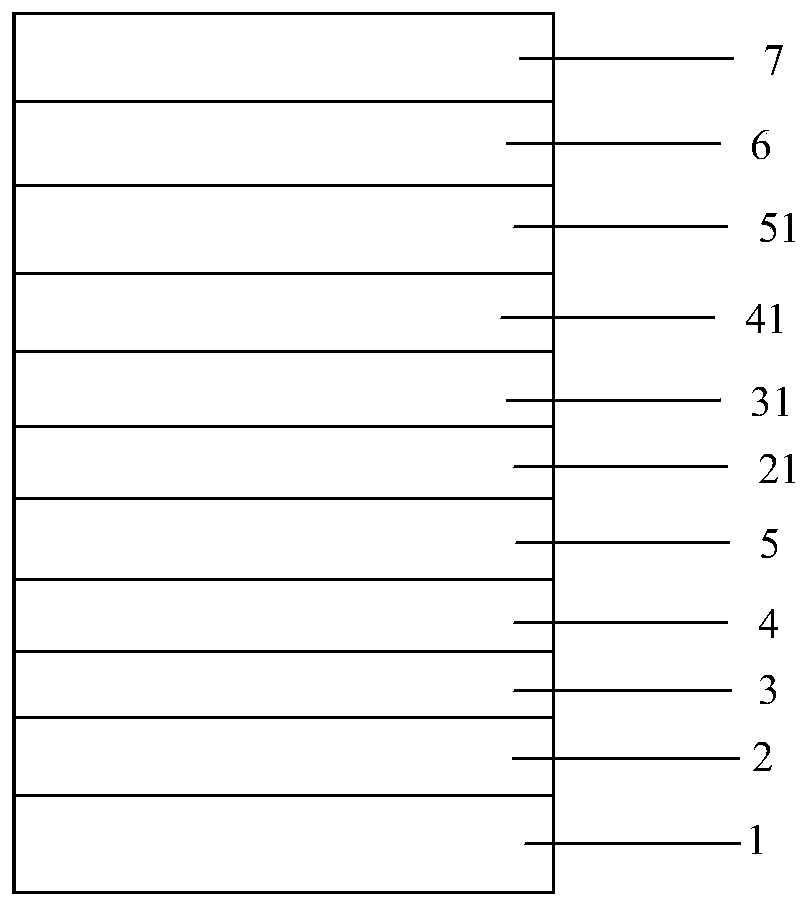

[0061] On the glass substrate 2.0C (substrate), sequentially plate Si with a thickness of 30nm 3 N 4 Film layer; ZnO with a thickness of 9nm 2 The film layer is used as a dielectric film layer; a GaMg interface film layer with a thickness of 1nm, wherein the Ga content is 66at%; a silver film layer with a thickness of 12nm; a NiCr film layer (sacrifice film layer) with a thickness of 2nm; a ZnSnO film layer with a thickness of 28nm 2 layer (top dielectric layer); Si with a thickness of 10nm 3 N 4 The film layer is used as a protective film layer to obtain heat-treatable coated glass, that is, a thin-film device.

[0062] Optical performance test:

[0063] Before heat treatment, the visible light transmittance of a single piece of coated glass is 82.1%; after heat treatment at 580°C for 10 minutes, the visible light transmittance of a single piece of coated glass is 83.3%, and the square resistance is 4.0Ω / □; then washing, assembling, etc. The visible light transmittance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap