Control valve of high-pressure automatic steam pot

A high-pressure gas and control valve technology, applied in pressure cookers, safety valves, balance valves, etc., can solve the problems of inability to adjust and adjust at will, and achieve the effects of compact structure, reliable use and strong selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

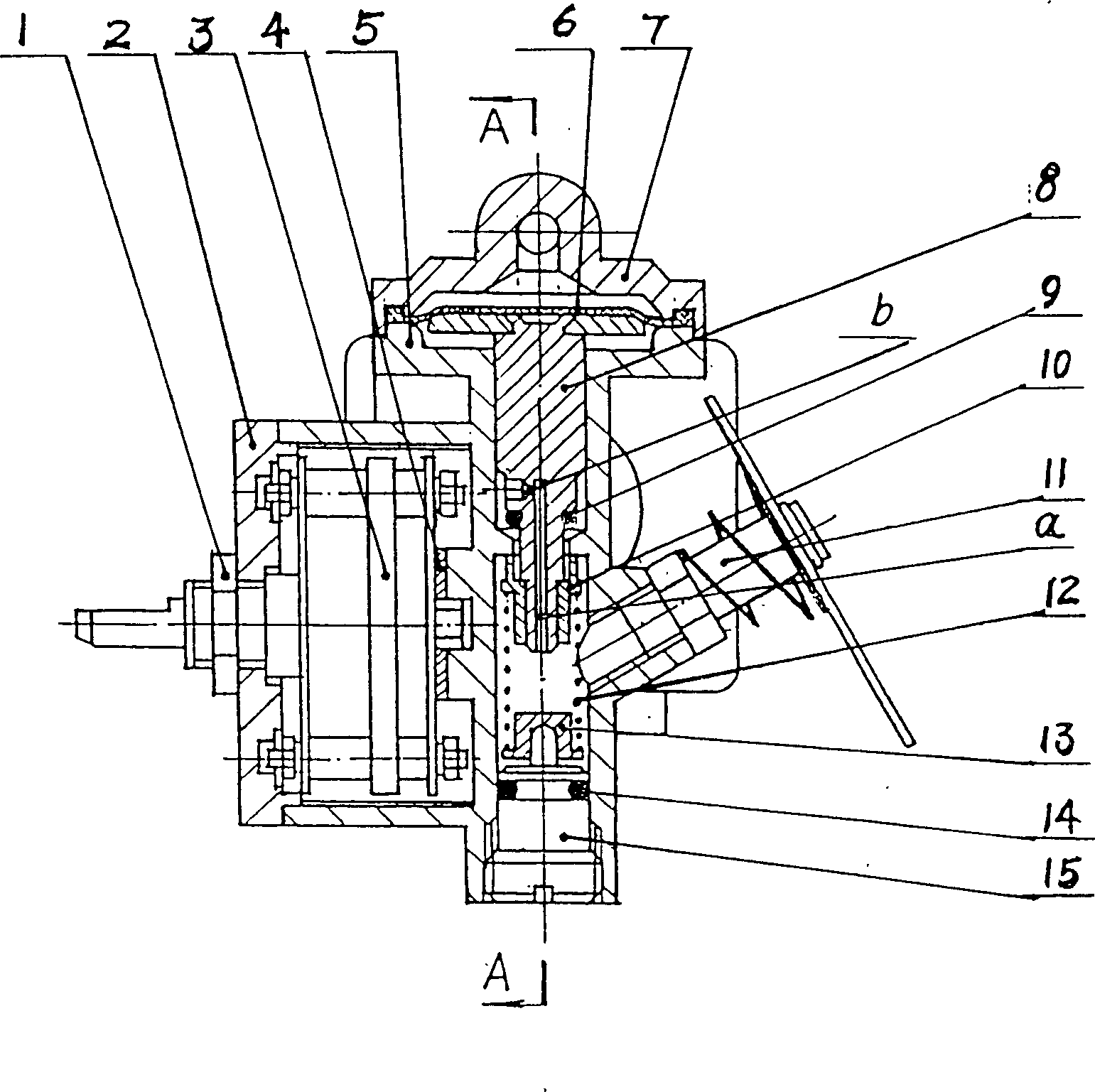

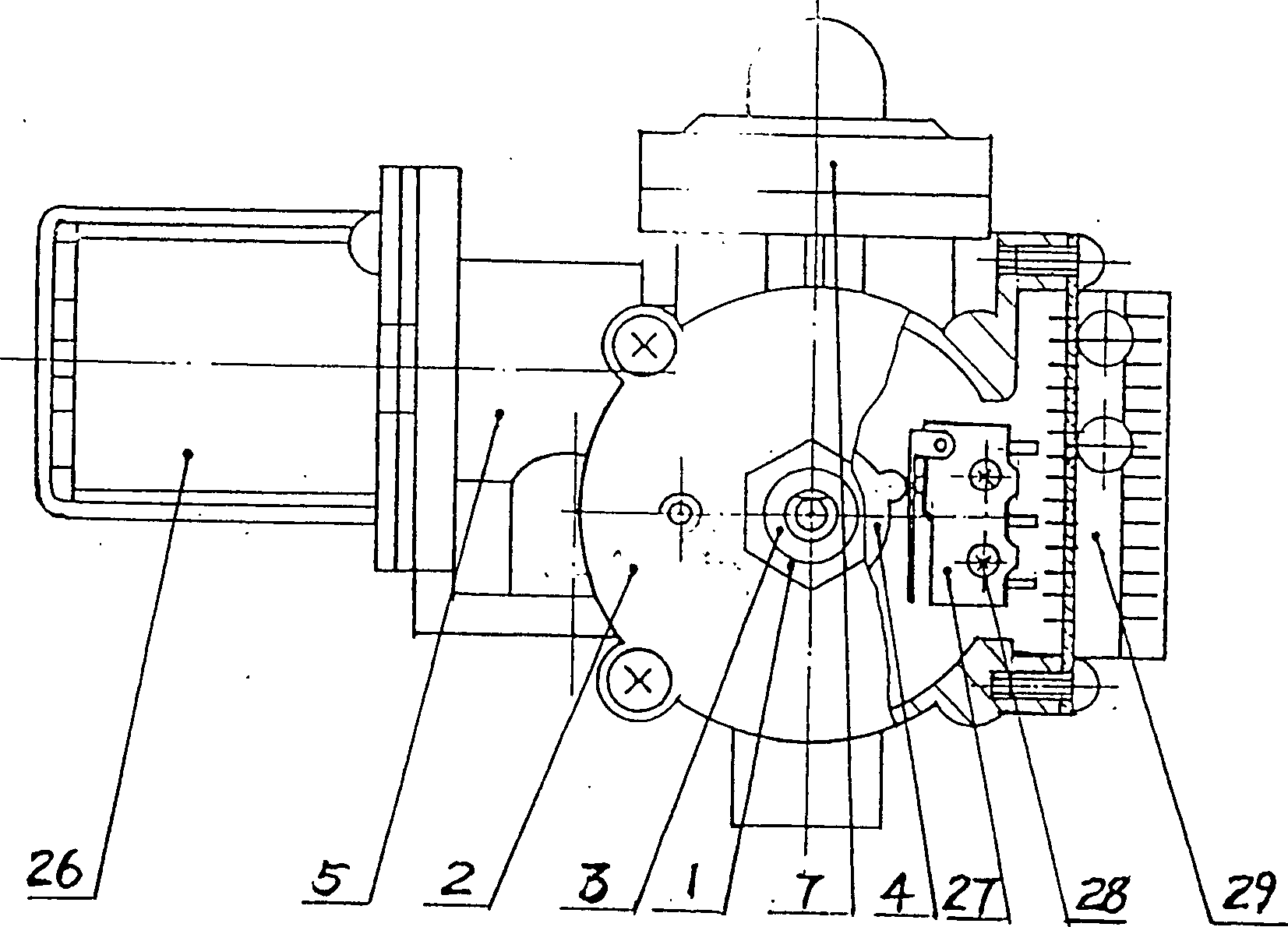

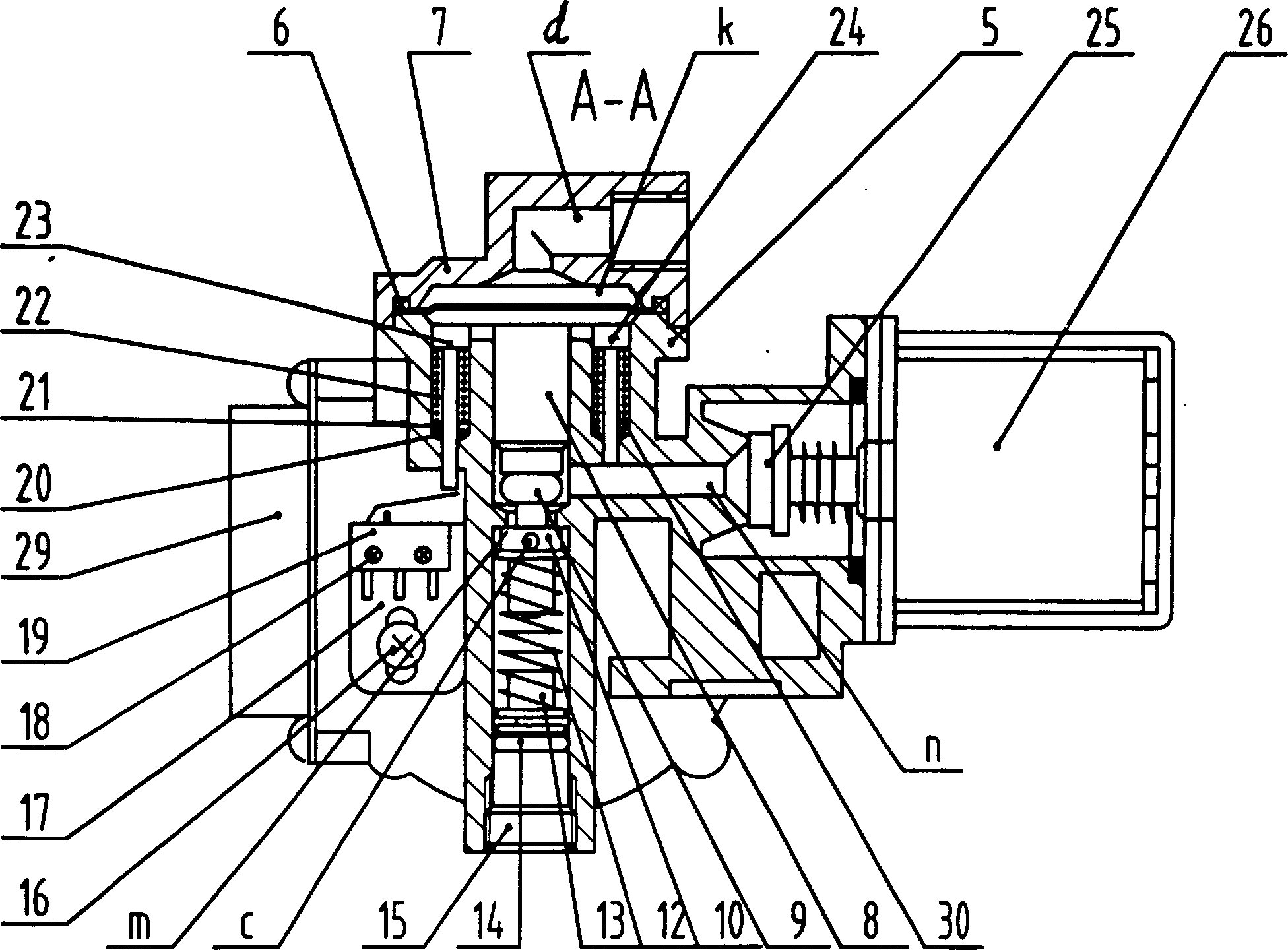

[0012] The structure of the control valve will be further described in detail in conjunction with the accompanying drawings:

[0013] The structure of the control valve can be roughly divided into a gas control part, a steam control part and an electronic control part. The gas control part is mainly composed of a solenoid valve 26, an O-ring 25, a valve body 5, a valve stem 8, an O-ring 9 and a nozzle 11. The steam control part is mainly composed of parts bonnet 7, valve body 5, diaphragm 6, valve stem 8, O-ring 9, spring cover 10, spring 12, spring sleeve 13, O-ring 14, and pressure adjustment screw 15. The electronic control part is mainly composed of parts band switch 3, cam 4, lock nut 1, cover 2, valve body 5, micro switch 19, micro switch 27, wire plug plate 29, ejector rod 23, spring 22, O-ring 20, Gasket 21 is formed.

[0014] Screw 28 fixes the micro switch 27 in the valve body 5 . The lock nut 1 fixes the band switch 3 on the cover 2 . The cam 4 is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com