Packer

A technology of packer and hydraulic cylinder, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the irreversible operation process, reduce the progress of oilfield development, and the packer cannot achieve multiple sealing and other problems to achieve the effect of simple and convenient control and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

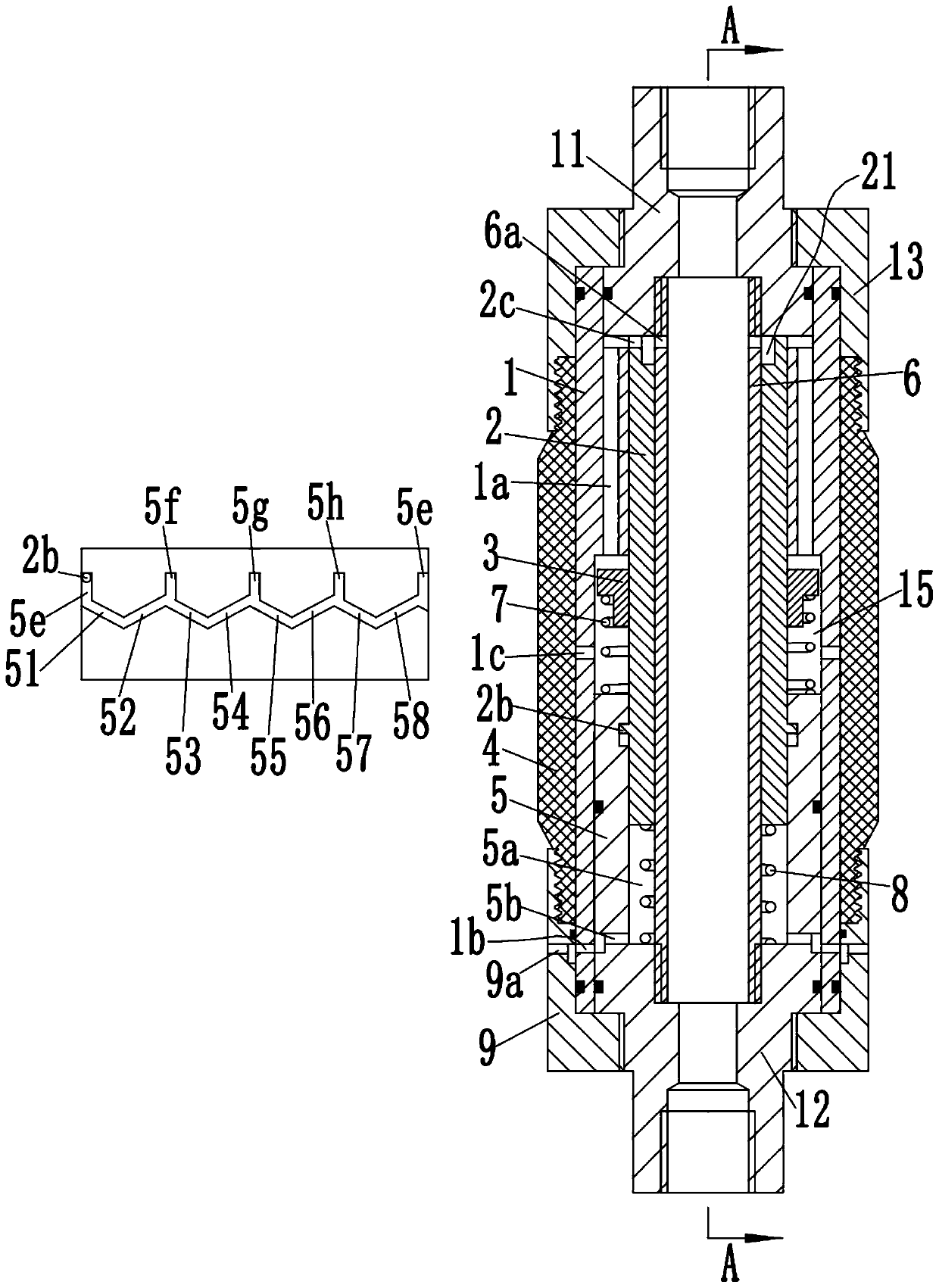

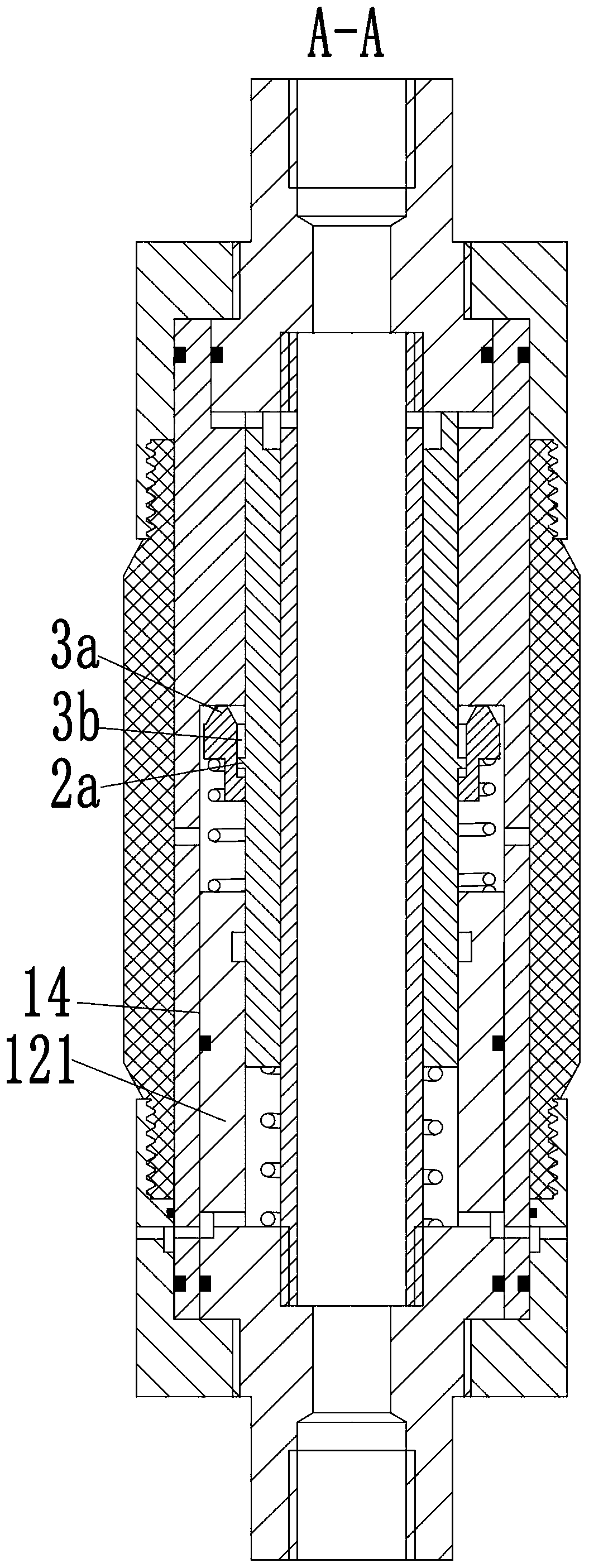

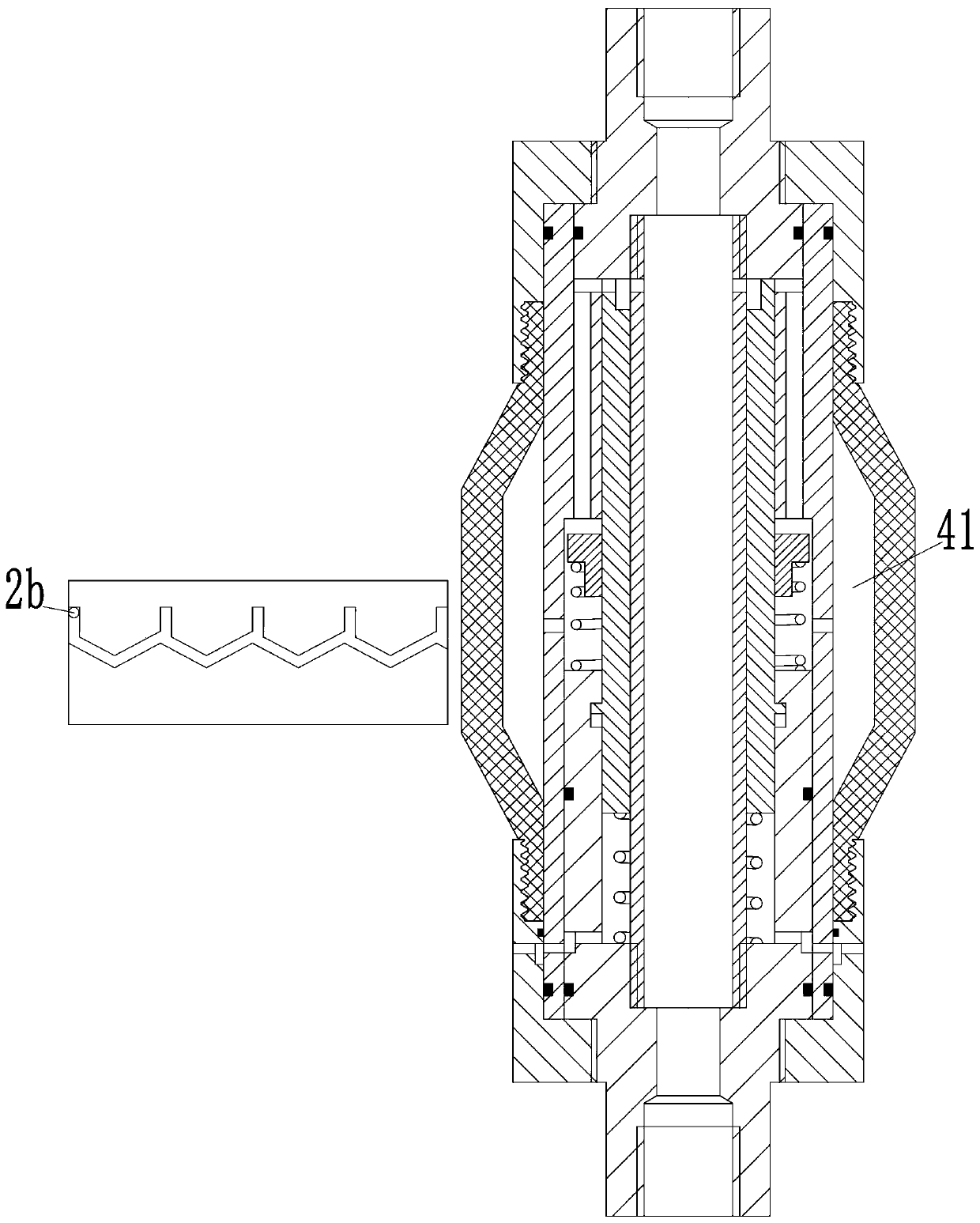

[0024] see Figure 1-9 As shown, a packer includes a hydraulic cylinder 2, an inner cylinder liner 6 is arranged on the inner side of the hydraulic cylinder 2, and an outer cylinder liner 1 is arranged on the outer side of the hydraulic cylinder 2, and the hydraulic cylinder 2 can Sliding relative to the inner cylinder liner 6 and the outer cylinder liner 1, supporting the upper sub-section 11 and the lower sub-section 12 of the hydraulic cylinder 2, forming between the upper sub-section 11 and the upper end of the hydraulic cylinder 2 There is a stress groove 21 to drive the hydraulic cylinder 2 to move downward, and a first spring 8 is arranged between the lower joint 12 and the lower end of the hydraulic cylinder 2 to drive the hydraulic cylinder 2 upward. Movement, the outer side of the outer cylinder liner 1 is also provided with an expandable and retractable rubber tube 4 . The upper short joint 11 is fixedly installed with an upper connecting sleeve 13 fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com