Muddy water and earth pressure double-mode shield system and control method

A dual-mode, mud-water-soil technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as troublesome operation, reduce labor intensity, reduce transportation difficulty, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

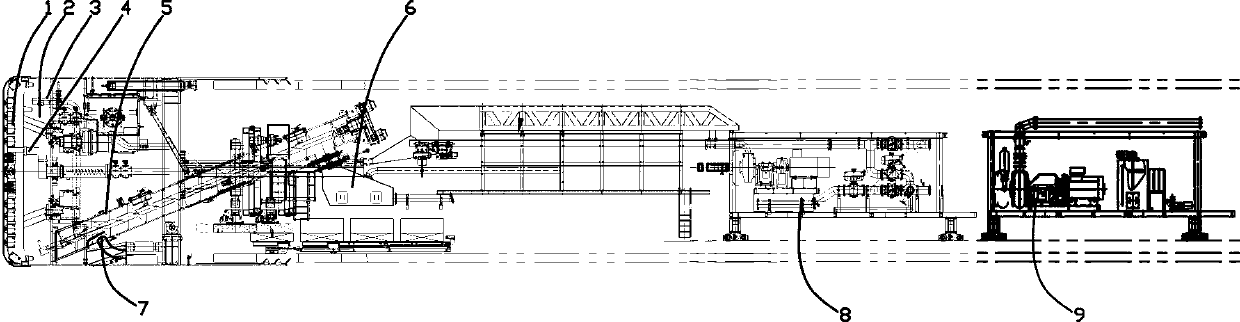

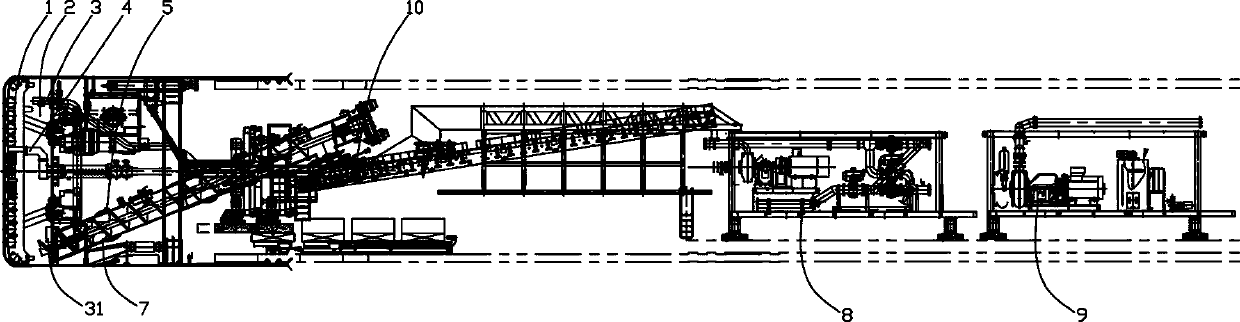

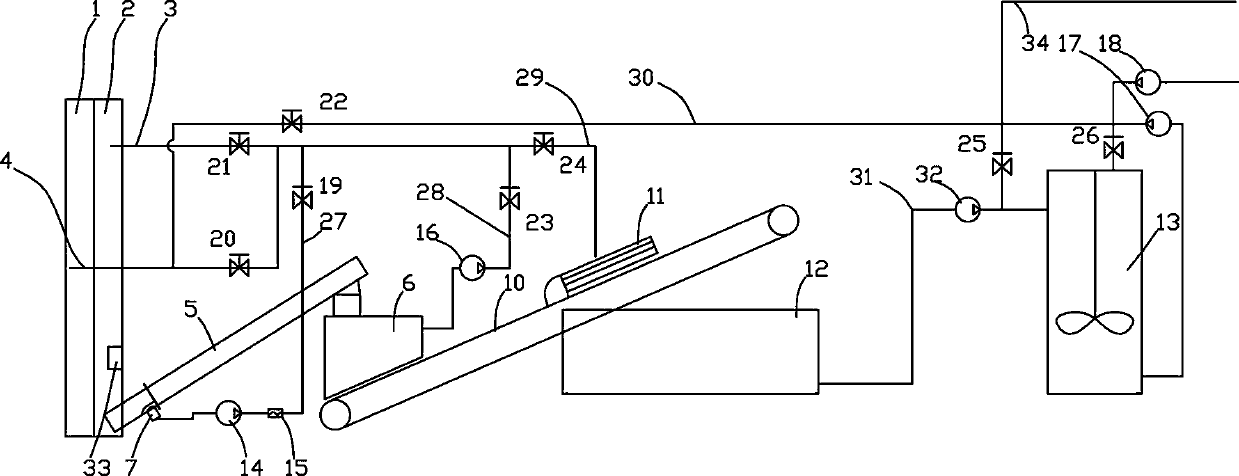

[0037] Such as Figure 1~3 Among them, a mud-water-earth pressure dual-mode shield system includes a shield part, a mud separation trolley 8 and a bentonite mud preparation trolley 9 following the shield part; the mud separation trolley 8 is provided with a mud separation device, It is used to separate mud and stones on site, so that mud can be recycled as much as possible, saving resources and reducing energy consumption. It is also convenient for the transportation of gravel and avoids mud dripping onto the road during the process of transporting gravel. The bentonite slurry preparation trolley 9 is used to prepare bentonite slurry for lubricating and cooling the shield cutter head 1 .

[0038] A shield cutterhead 1 is provided at the front end of the shield part, and an earth bin 2 is arranged behind the shield cutter head 1, and the entrance of the screw conveyor 5 is obliquely connected to the lower section of the earth bin 2; the screw conveyor 5 rotates shaft blades ,...

Embodiment 2

[0055] Such as Figure 1~3 Among them, a construction method using the above mud-water-soil pressure dual-mode shield tunneling system, in the earth pressure balance shield working condition, close the first circulation valve 19 on the first circulation pipe 27, and open the gate of the quarry box 6 The plate 64 adjusts the rotation speed of the screw conveyor 5 according to the soil bin pressure sensor 33 provided in the soil bin 2, so that the pressure in the soil bin 2 meets expectations. The stones at the outlet of the screw conveyor 5 are discharged to the conveyor belt 10 through the quarry box 6, and the stones or gravels are transported to the outside of the cave from the subsequent conveyor belt 10 or the slag transport trolley for earth pressure shield construction;

[0056] In the mud-water balance shield working condition, start the first mud circulation pump 14, open the first circulation valve 19 of the first circulation pipe 27, and the first mud circulation pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com