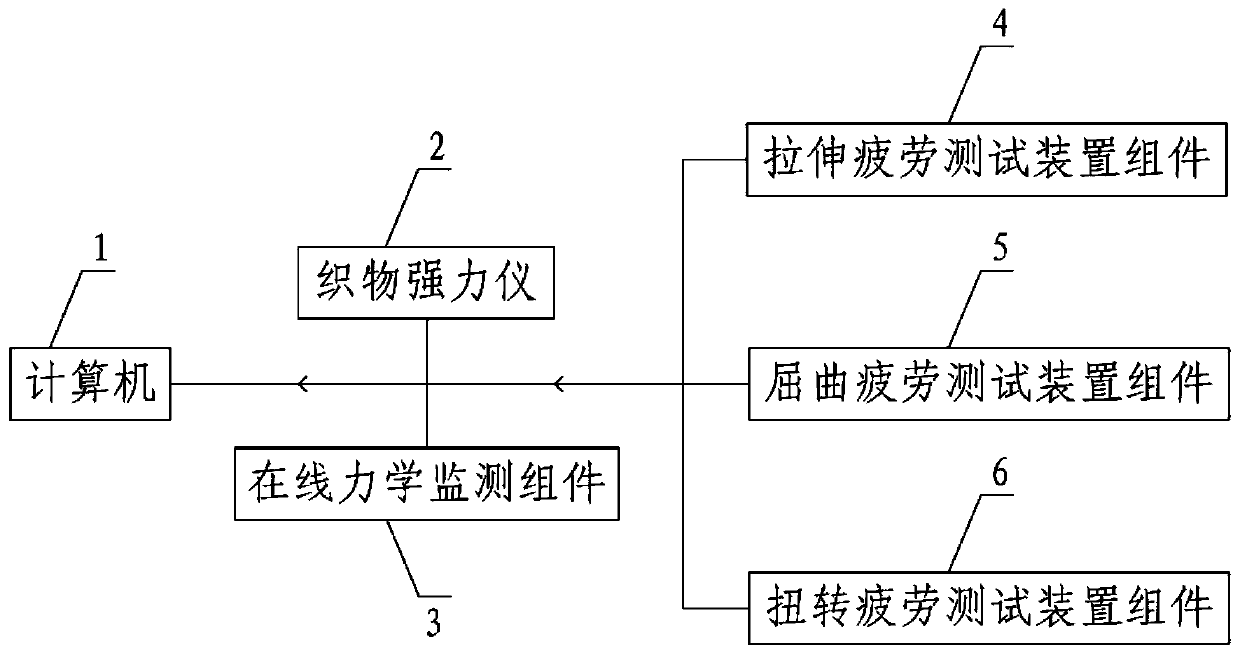

Artificial ligament in-vitro simulation fatigue simulation and online mechanical monitoring synchronous test device and method

An artificial ligament, synchronous testing technology, used in measuring devices, testing material strength using repetitive force/pulse force, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example records a fatigue simulation test method for artificial ligament in vitro simulation. The specific test steps are as follows:

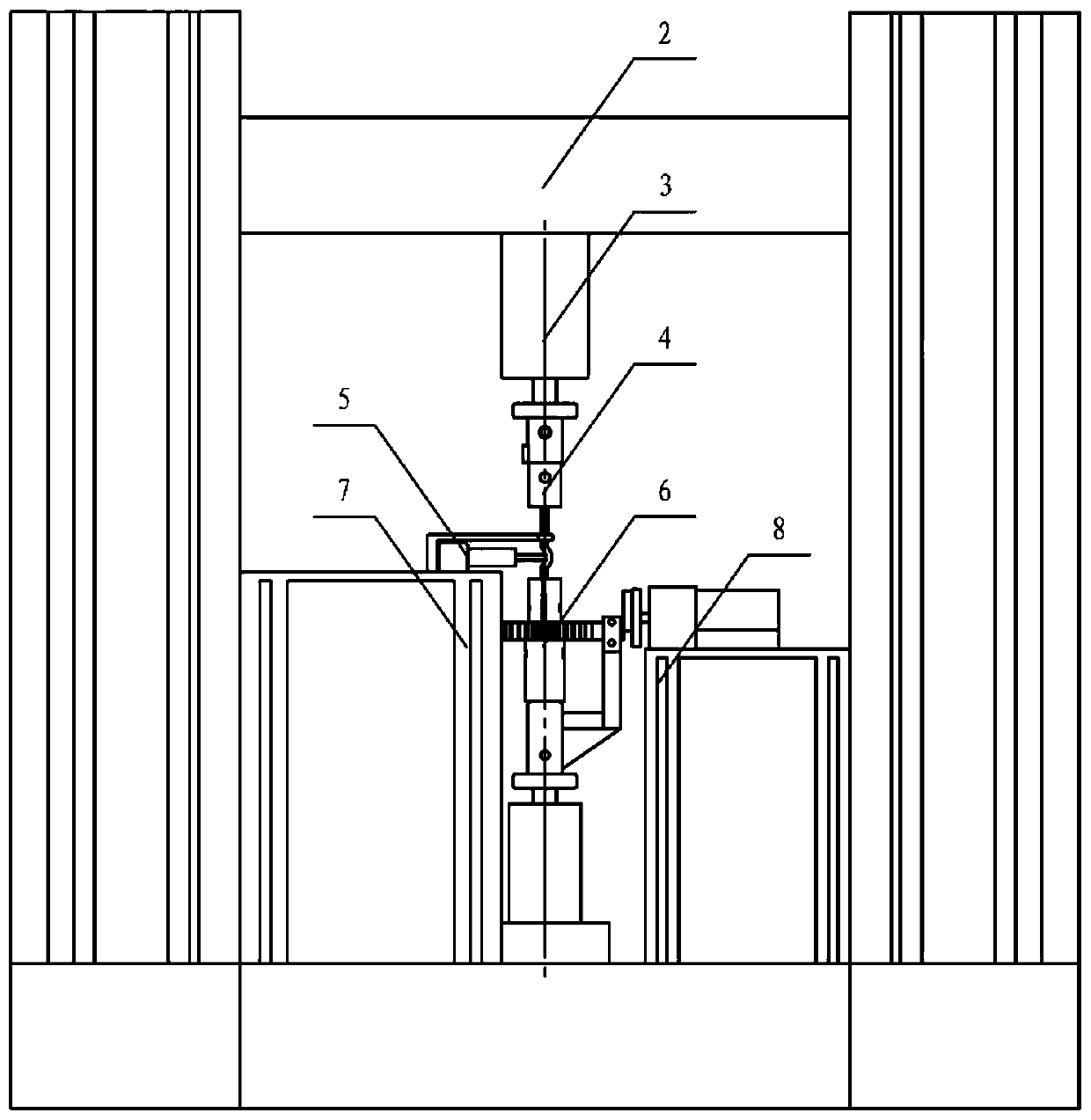

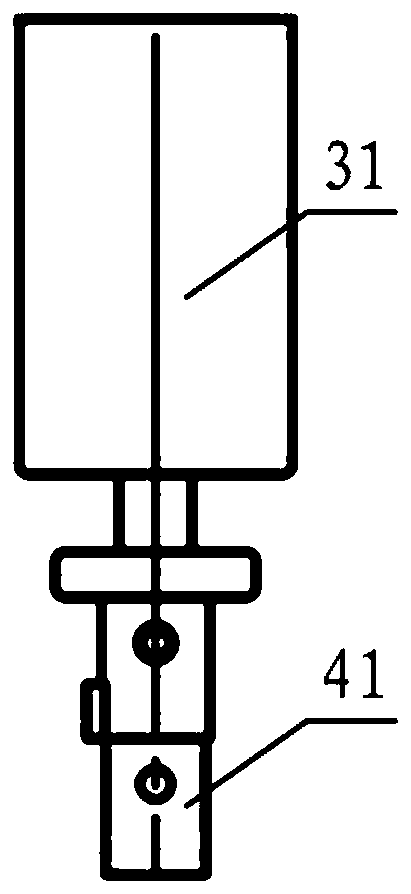

[0044] (1) Prepare experimental materials: prepare a force sensor 31 with a measuring range of 500N, a torsion gear 63 with a radius of 25mm, a turntable 66 with a radius of 30mm, a connecting rod 68 with a length of 80mm, and a rack 69 with a length of 80mm. Prepare the artificial ligament sample A1, the length L1 is 30 mm, the diameter D1 is 5 mm, without coating;

[0045] (2) Check parts and install samples: the tensile fatigue testing device assembly 4 is connected and fixed with the fabric strength meter 2 through threads, and the upper clamping device 41 clamps the upper end of the artificial ligament sample A1; the torsional fatigue testing device assembly 6 is The connecting base 65 of the fabric strength meter is connected and fixed to the fabric strength meter 2 through the leading pin, and the rack 69 is adjusted to the ...

Embodiment 2

[0052] This example records a fatigue simulation test method for artificial ligament in vitro simulation. The specific test steps are as follows:

[0053] (1) Prepare experimental materials: prepare a mechanical sensor 31 with a measuring range of 500N, prepare a torsion gear 63 with a radius of 30mm, prepare a turntable 66 with a radius of 40mm, prepare a connecting rod 68 with a length of 75mm, and prepare a rack 69 with a length of 85mm. Prepare the artificial ligament sample A2, the length L2 is 30 mm, the diameter D2 is 5.5 mm, without coating;

[0054] (2) Check the parts and install the sample: the tensile fatigue testing device assembly 4 is connected and fixed with the fabric strength meter 2 through threads, and the upper clamping device 41 clamps the upper end of the artificial ligament sample A2; the torsional fatigue testing device assembly 6 is The connecting base 65 of the fabric strength meter is connected and fixed with the fabric strength meter 2 through the ...

Embodiment 3

[0061] This example records a fatigue simulation test method for artificial ligament in vitro simulation. The specific test steps are as follows:

[0062] (1) Prepare experimental materials: prepare a force sensor 31 with a measuring range of 500N, a torsion gear 63 with a radius of 30mm, a turntable 66 with a radius of 45mm, a connecting rod 68 with a length of 80mm, and a rack 69 with a length of 80mm. Prepare the artificial ligament sample A3, the length L3 is 40mm, the diameter D3 is 5.5mm, without coating;

[0063] (2) Check parts and install the sample: the tensile fatigue testing device assembly 4 is connected and fixed with the fabric strength meter 2 by threads, and the upper clamping device 41 clamps the upper end of the artificial ligament sample A3; the torsional fatigue testing device assembly 6 is The connecting base 65 of the fabric strength meter is connected and fixed to the fabric strength meter 2 through the leading pin, and the rack 69 is adjusted to the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com