Method for testing tactile viscosity of adhesive and fixing device

A technology of fixing devices and adhesives, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem of not seeing the repeatability test result data of pressure-sensitive adhesives, and achieve the reduction of test uncertainties, easy operation, and high precision The effect of test result data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0051] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0052] The so-called "test piece" refers to the sample piece coated with adhesive or the sample piece to be adhered by adhesive, wherein the former is a sample strip, sample tape or sample block with a certain size and specification coated with adhe...

Embodiment 1

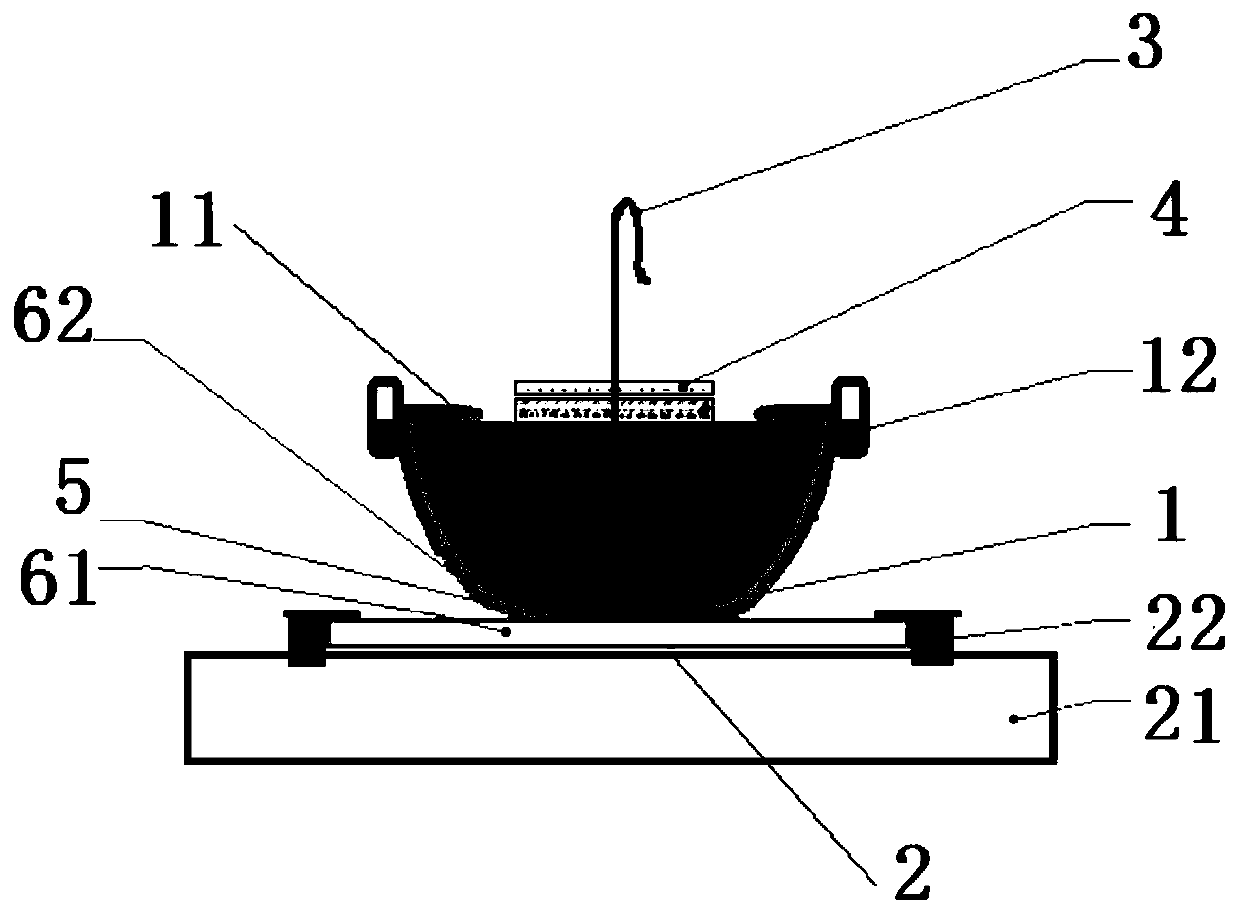

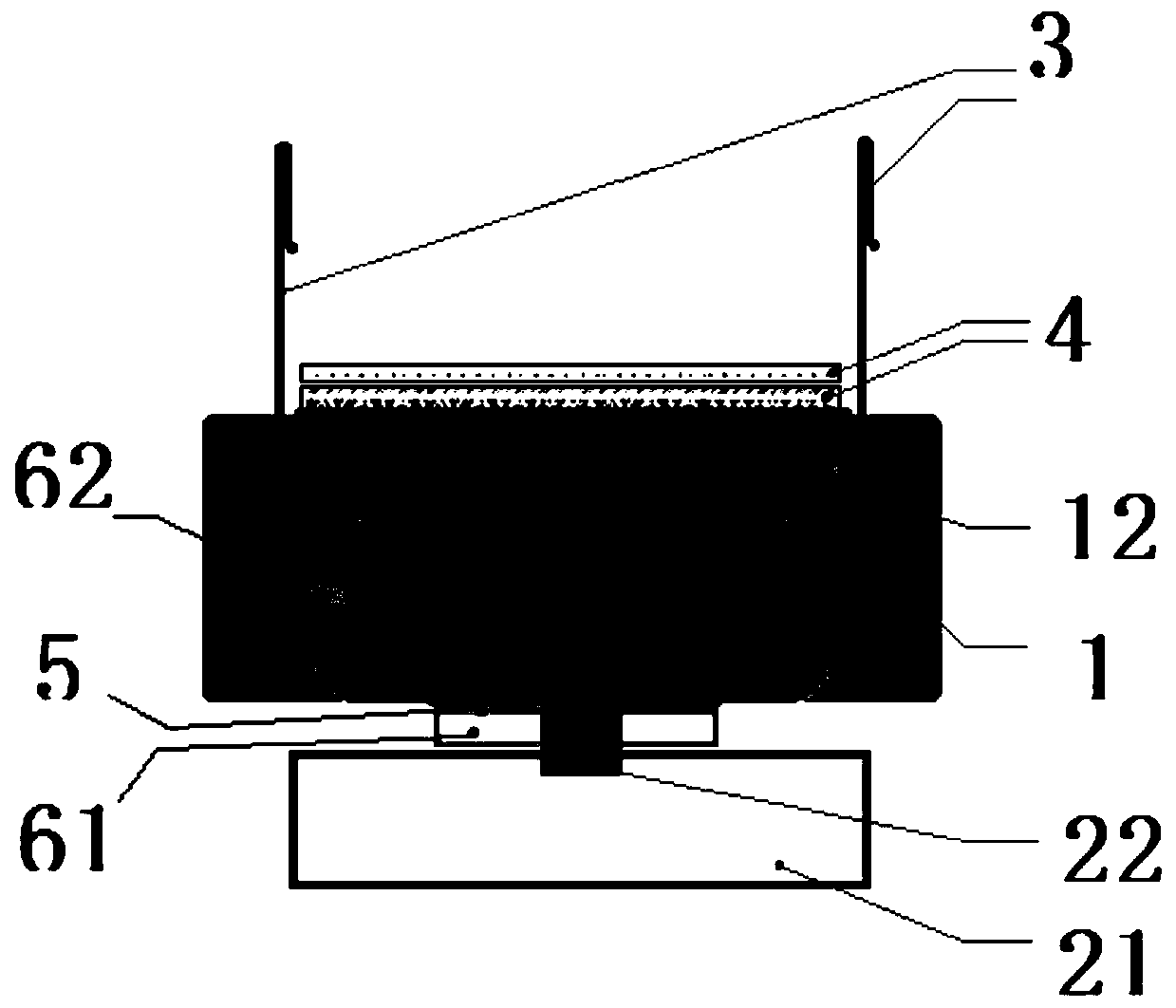

[0056] Such as Figure 1-Figure 2 Shown, a kind of fixing device of testing adhesive touch tackiness, described fixing device comprises:

[0057] The upper fixture 1 and the lower fixture 2, the upper fixture 1 and the lower fixture 2 are arranged up and down on the axis perpendicular to the ground and can move relative to each other; the upper fixture 1 and the lower fixture 2 are used to fix the test piece 61 / 62, wherein, after the test piece 62 fixed by the upper clamp contacts with the test piece 61 fixed by the lower clamp, the adhesive surface 5 is formed; the surface of the test piece 62 is coated with the adhesive to be tested, and the surface of the test piece 61 may be Coated with adhesive, the test piece 61 may also be an adherend that is not coated with adhesive;

[0058] a hook 3, the hook 3 is arranged on the top of the upper fixture 1, and is fixedly connected with the upper fixture 1;

[0059] The mass assembly 4, the mass assembly 4 is located above the upp...

Embodiment 2

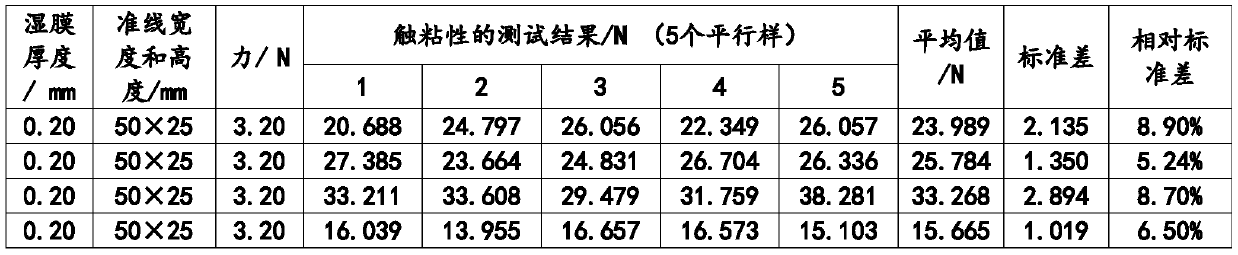

[0070] The operation steps of the touch tack test of different adhesives:

[0071] 1. Preparation of test pieces and testing steps:

[0072] 1.1 Use a cutting knife to cut a sufficient number of test pieces of specified size on the substrate material to be loaded with adhesive (pressure-sensitive adhesive tapes used at room temperature do not require adhesive brushing and activation steps, and can be followed up after cutting and fixing) testing; PSAs without a substrate need to be coated on a relevant substrate of a certain size before being fixed and tested).

[0073] 1.2 The test piece should be treated accordingly.

[0074] 1.3 Brush the fluid adhesive on the test piece with a brush or other tools to become a test piece. It is required to paint thinly and evenly, without glue accumulation or lack of glue, preferably a wire bar coater with a nominal 200μm. Then activate the adhesive on the test piece (water-based or solvent-based adhesives can be dried and activated by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com