Permanent magnet synchronous motor and assembling method

A permanent magnet synchronous motor and assembly method technology, which is applied to synchronous motors with static armatures and rotating magnets, electromechanical devices, electric components, etc. The problem of increasing torque pulsation and affecting the operation of mechanical equipment can achieve the effect of simple structure, reducing cogging torque and torque pulsation, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

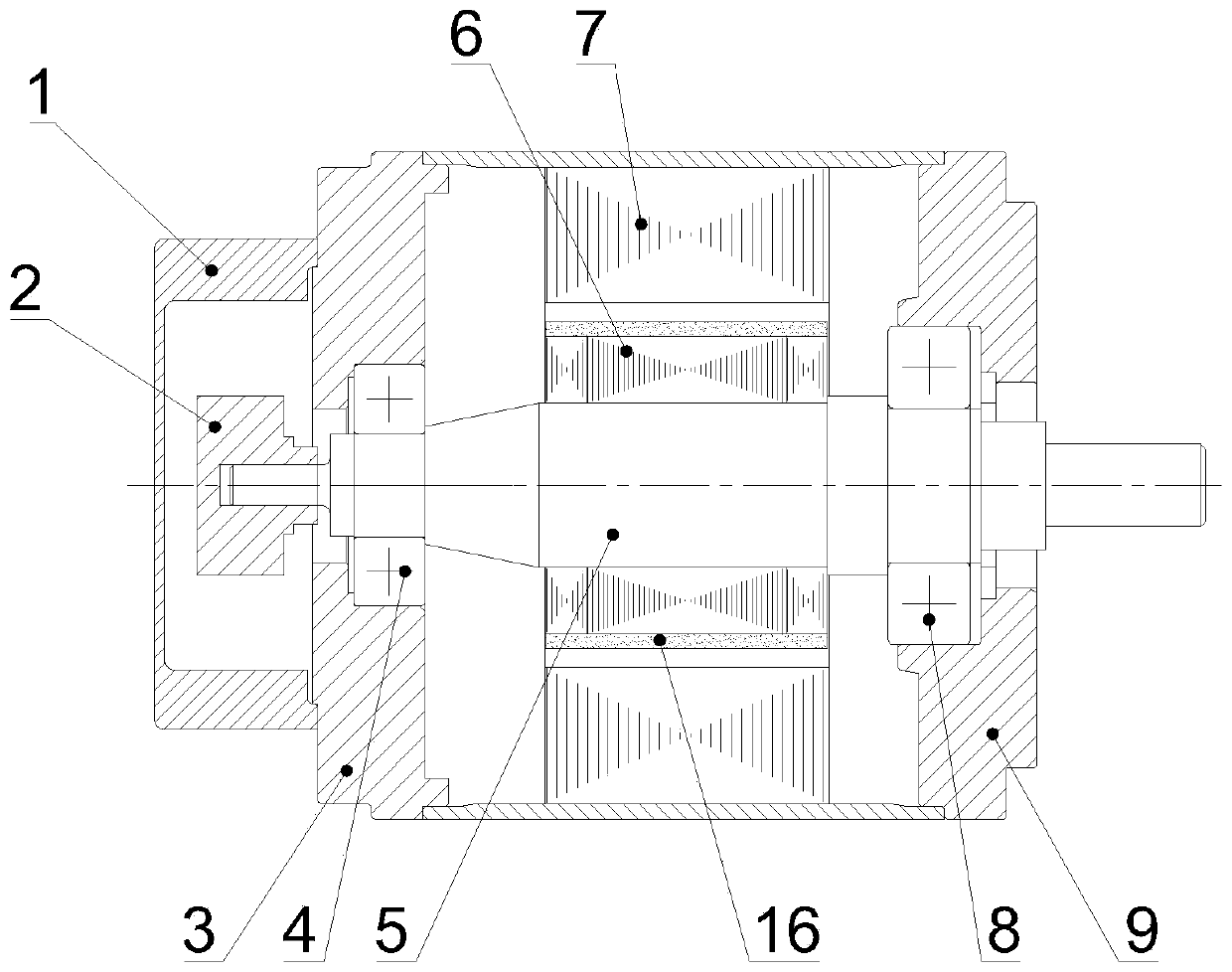

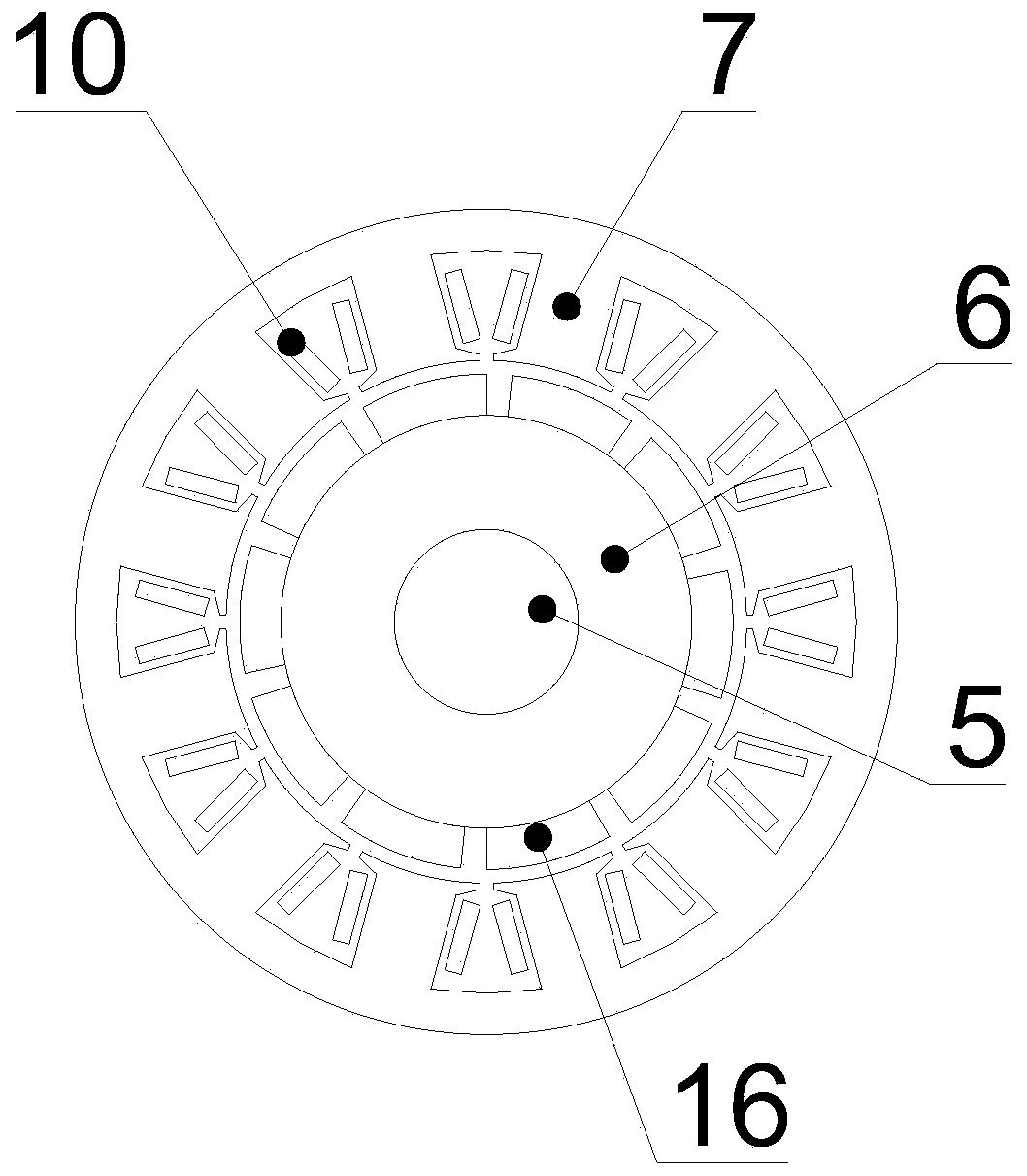

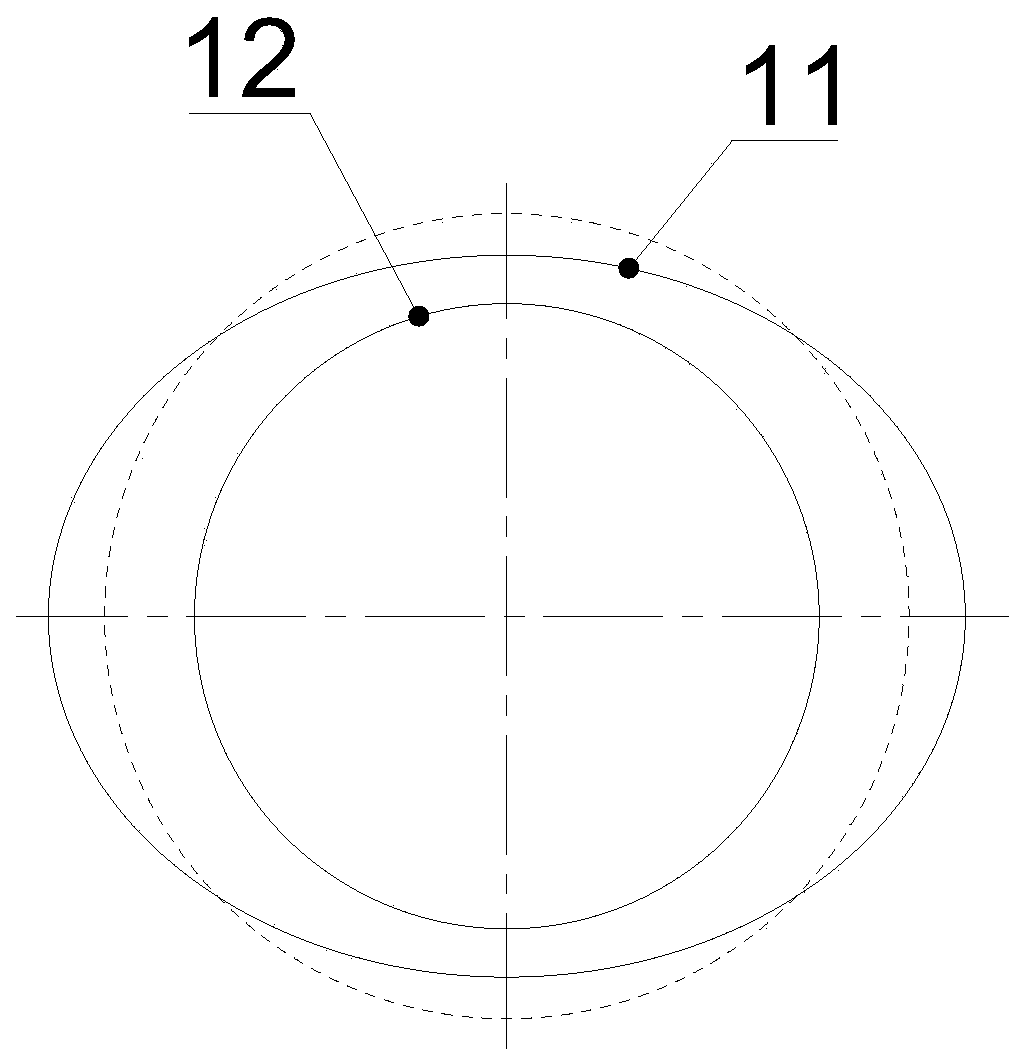

[0037] see Figure 4-Figure 7 , a permanent magnet synchronous motor according to this embodiment, comprising a casing, a stator 7, a rotor 6, a magnetic steel 16, a rotating shaft 5, a front end cover 9 and a rear end cover 3; the inner circle of the stator 7 is an ellipse; the rotor 6 is arranged in the stator 7, and the center of the rotor 6 is arranged on the minor semi-axis centerline of the inner circle of the stator 7 (and the center of the rotor 6 is not at the same point as the center of the inner circle of the stator 7). Wherein, the offset distance between the center of the rotor 6 and the center of the inner circle of the stator 7 is 0.01mm-0.1mm.

[0038] In the permanent magnet synchronous motor of this embodiment, by offsetting the rotor 6 to the short semi-axis of the ellipse 11 in the stator 7, the cogging torque and torque ripple are effectively reduced, which is conducive to improving the accuracy of the motor, thereby improving the performance of the corres...

Embodiment 2

[0051] In the step (4) of the assembly method of the permanent magnet synchronous motor, the front bearing 8 and the rear bearing 4 are respectively pressed into the corresponding positions of the rotor 6 by using a press bearing tooling and a hand press. Using a hand press to install the front bearing 8 and the rear bearing 4 is convenient for manual control of the installation accuracy, and is beneficial for workers to adjust according to the actual assembly situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com