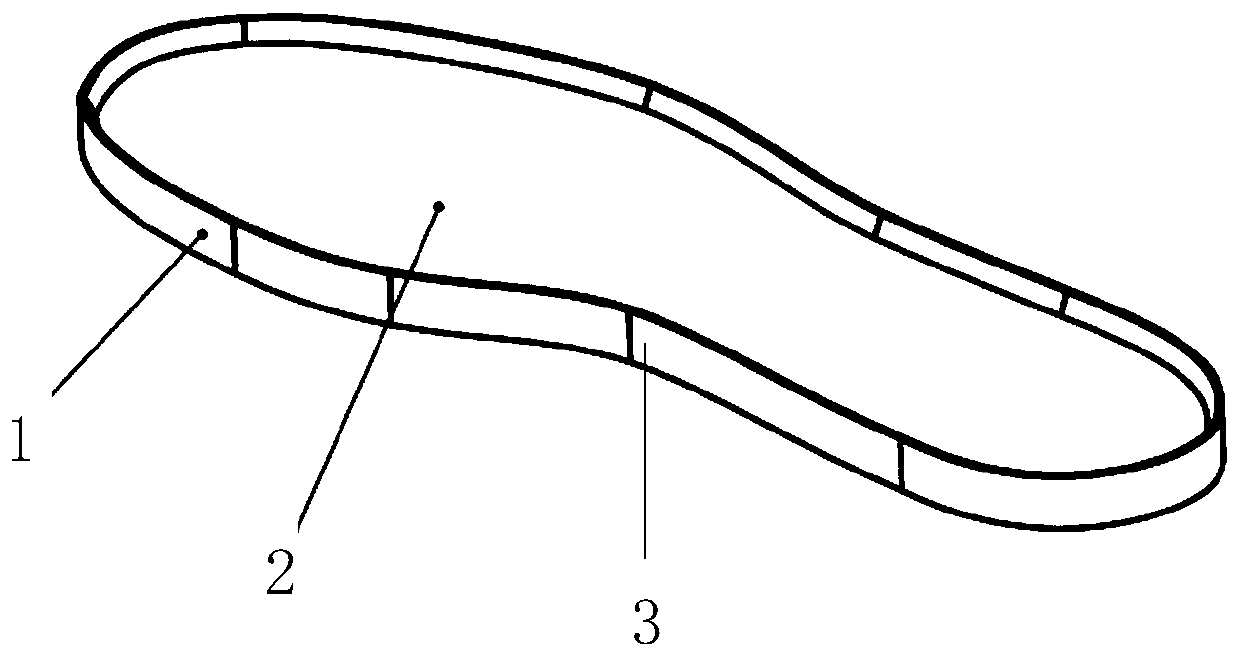

Vulcanized shoe foxing strip pressing device

A pressing device and vulcanized shoe technology, which is applied in the direction of footwear, gluing shoe parts, shoe-making machinery, etc., can solve the problems of accurately adjusting the concave part of the shoe, not adjusting, and the positioning accuracy is not high, so as to reduce uncertain factors, Guaranteed good health and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

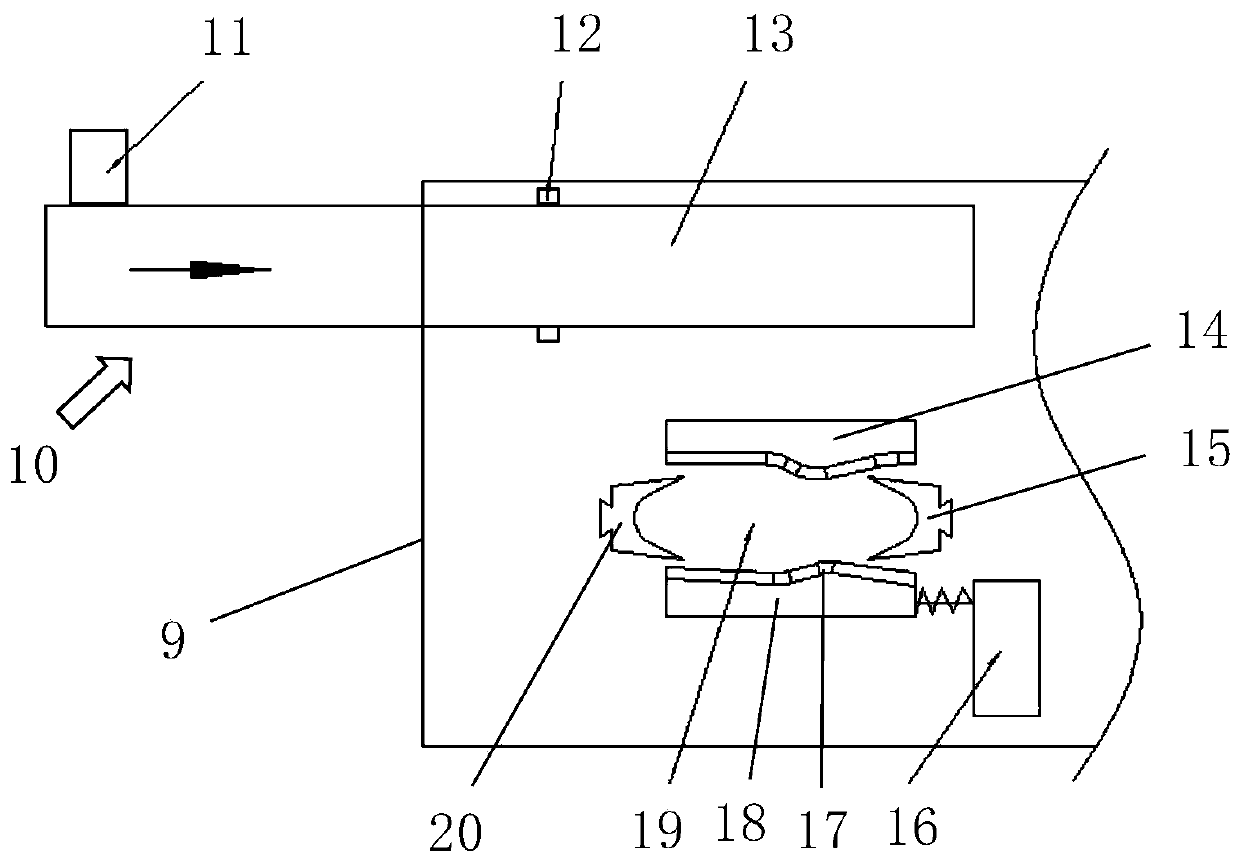

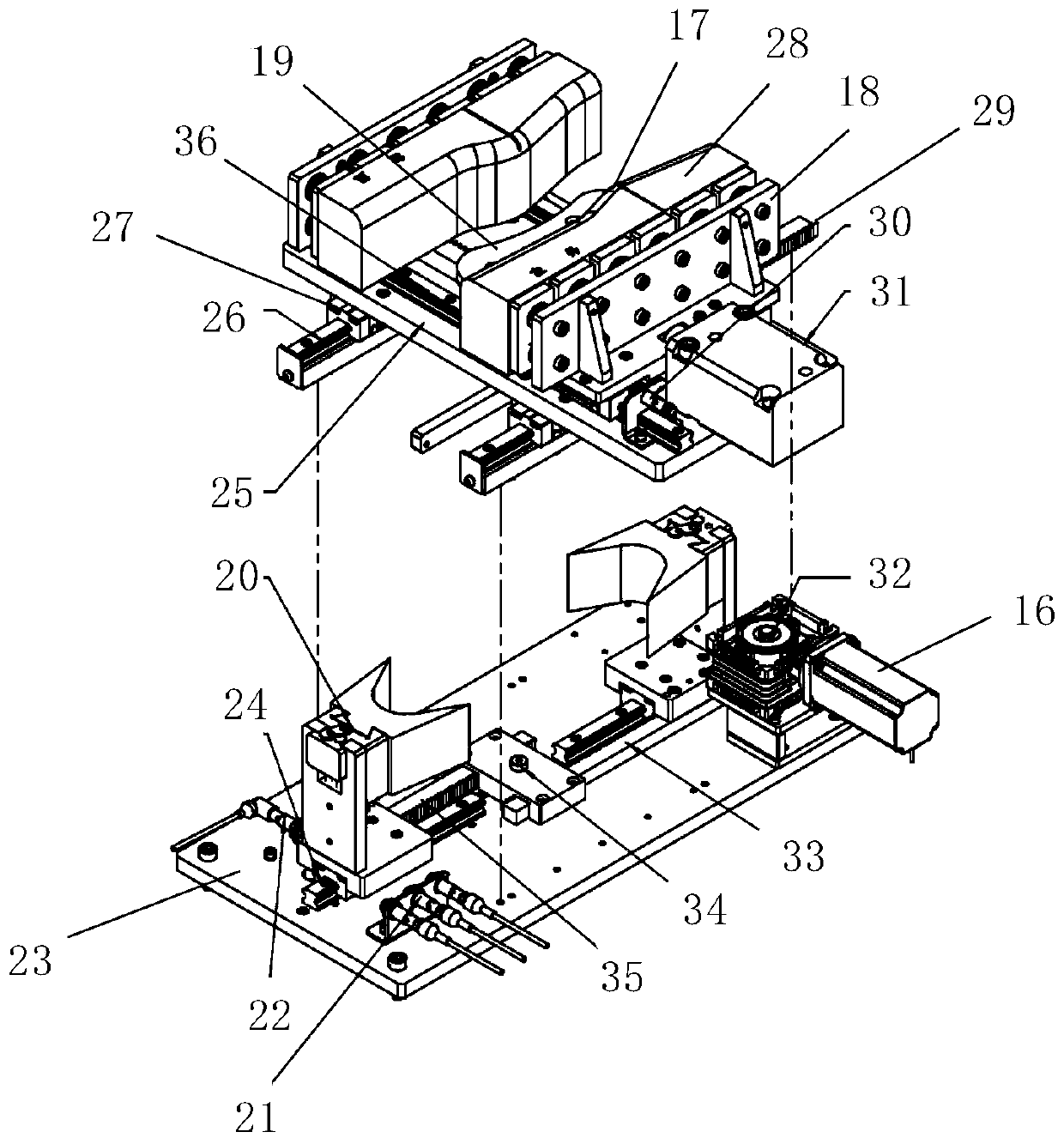

[0033] The invention is designed to solve the problem that in the existing vulcanized shoemaking industry, personnel in the process of pressing the enclosures come into close contact with the pressing mechanism, and the start and stop of the equipment is a foot switch, which poses health hazards to the operators. In order to avoid the same disadvantages in the device of the present invention in the past, a new automatic intelligent module design is carried out in the scheme, and the feeding part and the pressing part are partially used for safety protection, separating the operator from the moving parts, and providing safety protection for the operator effect.

[0034] The existing manufacturing process needs to rely on the operator to place the shoes to the designated position, and the problem of inaccurate placement will occur. Moreover, it is difficult for the operator to adjust the corresponding positional relationship between the notch on the side of the shoe and the bump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com