A camber grinding device

A technology of arc surface and grinding table, which is applied in the direction of grinding driving device, grinding/polishing safety device, grinding machine, etc., which can solve the problems of increasing workpiece cost, low grinding efficiency, and high grinding cost, so as to reduce requirements and improve grinding efficiency , Improve the effect of accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

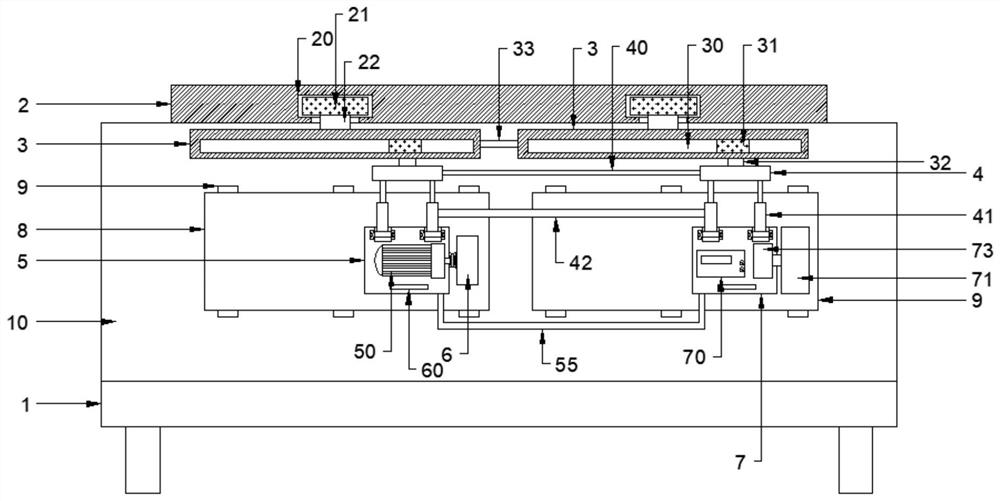

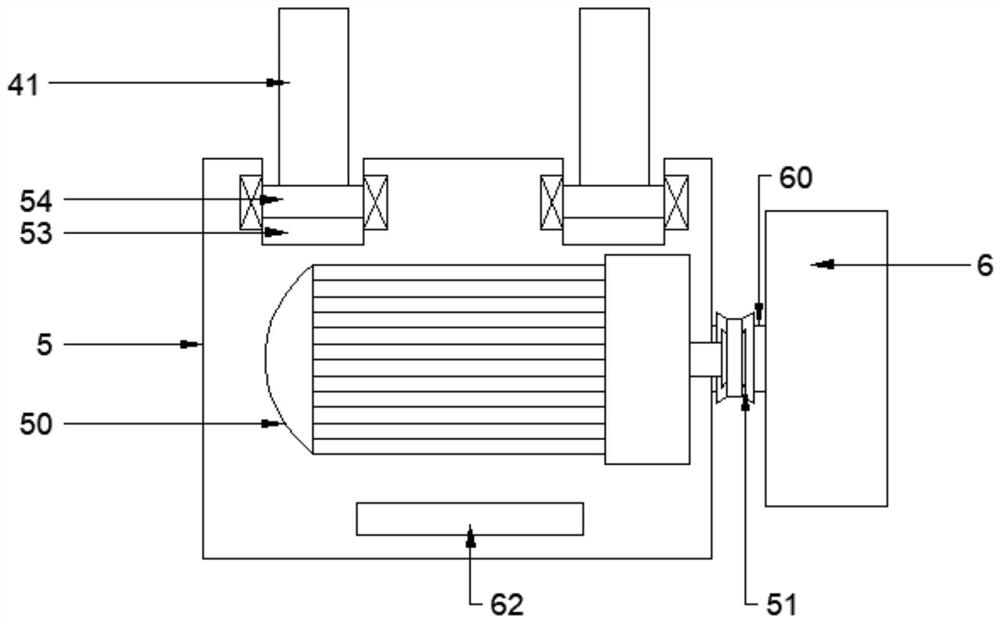

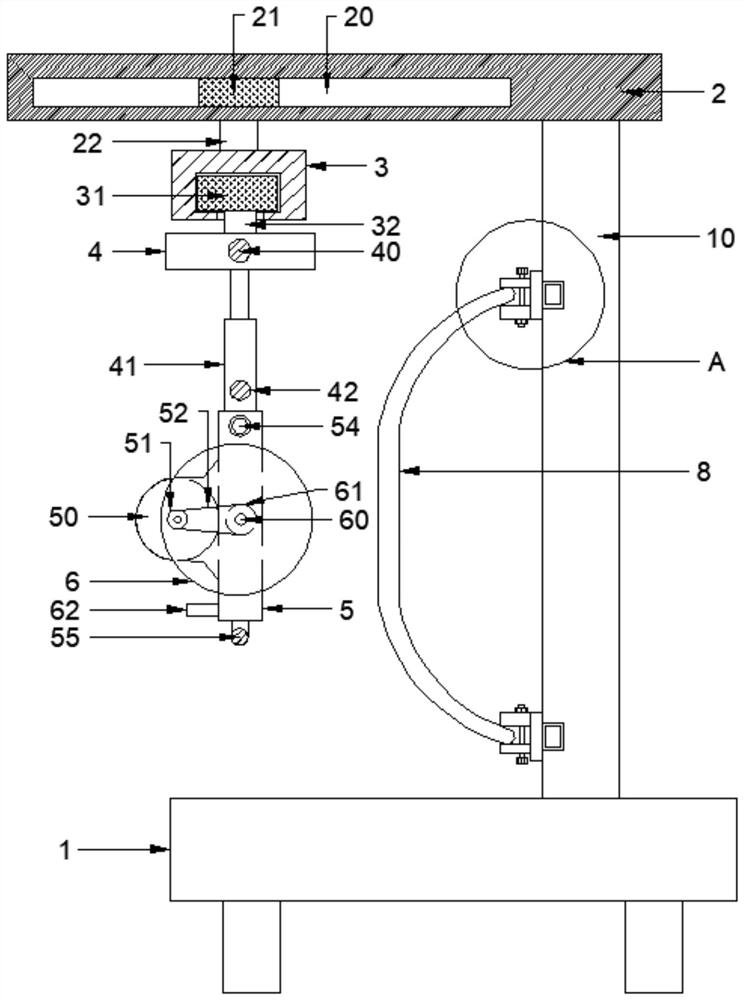

[0026] see Figure 1~6 , in an embodiment of the present invention, an arc surface grinding device includes a grinding table 1, a grinding wheel 6, and a grinding workpiece 8. A workpiece frame 10 is vertically fixed on the rear side of the top surface of the grinding table 1, so that Grinding workpiece 8 is clamped by a multifunctional fixture on the workpiece frame plate 10, and a suspension table 2 opposite to the top surface of the grinding table 1 is fixed on the top position of the front panel of the workpiece frame plate 10. The bottom surface of the suspension table 2 is suspended for Grinding wheel disc 6 of grinding workpiece 8 grinding, the mold workpiece 9 that has been polished is installed on the panel of described workpiece holder plate 10, and grinding workpiece 8 and mold workpiece 9 are located on the same horizontal plane and vertical plane together, and described mold A contour positioning wheel 71 on the same horizontal plane and vertical plane as the grin...

Embodiment 2

[0036] see Figure 4 , the difference between this embodiment and embodiment 1 is:

[0037] Described multifunctional fixture comprises fixture seat 14, and the vertical section of described fixture seat 14 is L-shaped, and described fixture seat 14 rear panel is rotated and fixed fixture seat connecting rod 13, and described fixture seat connecting rod 13 rear ends are fixed on On the front panel of the clamp slider 12, the overall slide of the clamp slider 12 is set in the clamp chute 11, and the clamp chute 11 is horizontally set on the workpiece holder plate 10, and the front panel of the clamp seat 14 is vertical The splint chute 16 is provided in the direction, and the movable splint 15 is slidably clamped on the splint chute 16, and the clamp mouth for clamping the side of the workpiece is enclosed between the grinding frame plate 5 and the protruding side wall of the front panel of the clamp seat 14. Fastening bolts 17 are threaded between the movable splint 15 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com