Bevel gear configuration coaxial double-rotor variable-speed transmission mechanism

A coaxial dual-rotor, variable-speed transmission technology, which is applied to gear transmissions, rotorcraft, and transmissions to drive multiple propellers, can solve the problems of low bearing capacity and low flight speed of high-speed helicopters, and achieve large transmission ratios , stable transmission and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

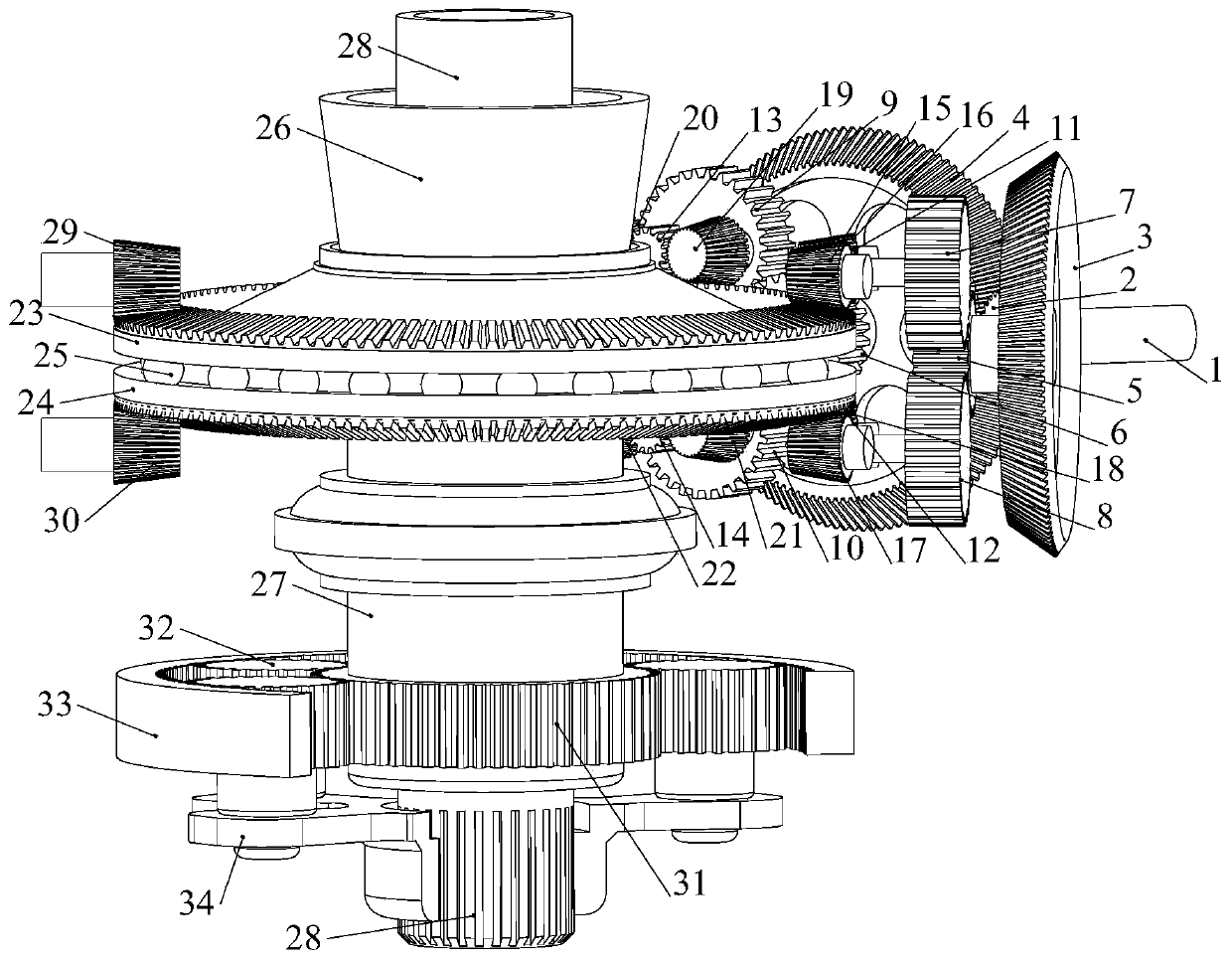

[0029] This embodiment provides a single-engine input bevel gear configuration coaxial double-rotor transmission mechanism, such as figure 1 As shown: it includes a graded reduction device and a coaxial reduction device; the graded reduction device includes a power input shaft 1, and the power input shaft 1 is fixedly connected to the primary driving wheel 2 to realize primary transmission; the primary driving wheel 2 It meshes with the first driven surface gear 3 and the second driven surface gear 4 at the same time, and adopts radial floating support to complete a power split; the first driven surface gear 3 and the second driven surface gear 4 pass through The split torsion shaft is fixedly connected with the first and second driving wheels 5 and the second driving wheel 6 respectively to realize two-stage transmission; the first and second driving wheels 5 are simultaneously connected with the first and second driven wheels 7 and the second driven wheels 8 meshing; the sec...

Embodiment 2

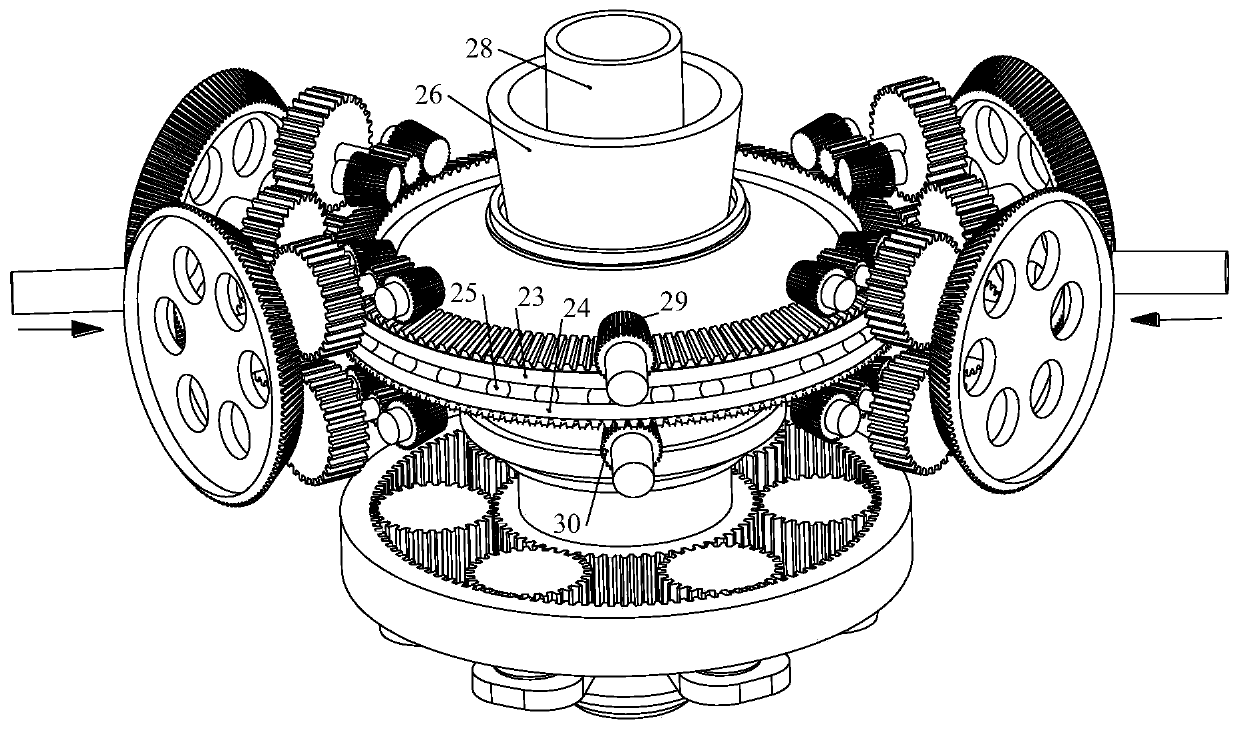

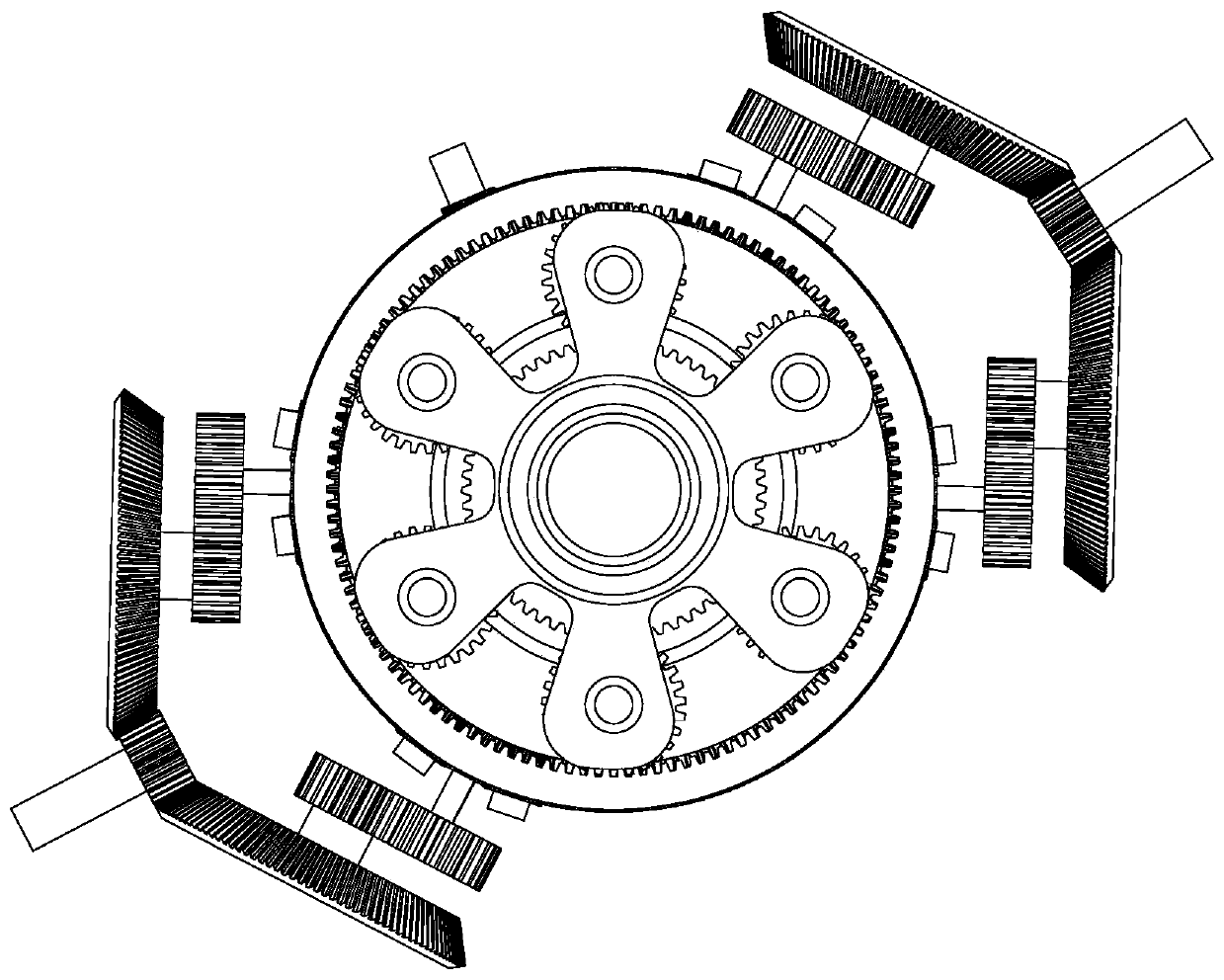

[0038] The bevel gear configuration coaxial double-rotor speed change transmission mechanism provided by the double engine input provided by this embodiment, such as figure 2 and image 3 As shown: the structure of this embodiment is the same as that of Embodiment 1, the difference is that this embodiment adopts dual-engine power input, has two sets of stepped reduction devices, and the configuration of the two sets of devices is the same, and they are distributed symmetrically or approximately symmetrically along the circumference .

[0039] Such as image 3 As shown, on the basis of the second embodiment, the lower rotor 36 connected with the first output shaft 26 and the upper rotor 35 connected with the third output shaft 28 are added, and the rest of the structure is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com