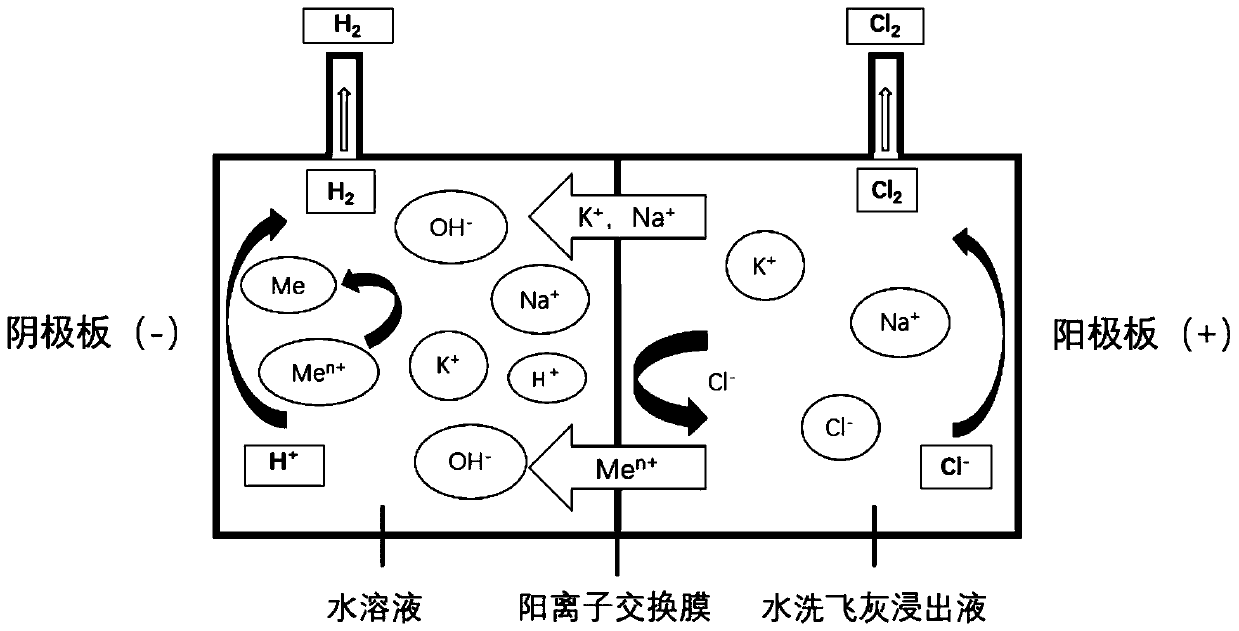

Electrochemical method for dechlorination and heavy metal removal for incineration fly ash water washing liquid

A technology for incinerating fly ash and heavy metals, applied in the field of water treatment, can solve the problems of forward osmosis membrane and draw liquid performance constraints, and achieve the effects of controllable reaction rate, energy saving, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

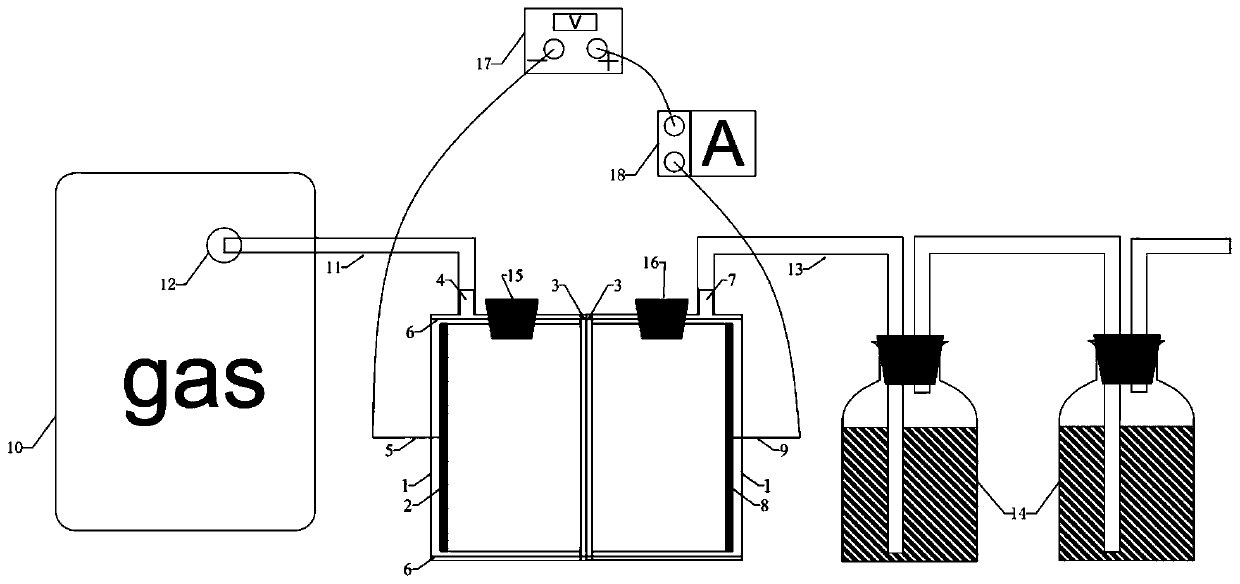

Embodiment 1

[0039]The total effective volume of the reactor is 49ml, and the effective volumes of the cathode chamber and the anode chamber are both 24.5ml. Both the cathode and the anode are titanium-plated rhodium oxide inert electrodes, and a constant current of 0.2A is fed to both ends of the electrolytic cell for a residence time of 3h. Cl in the washing liquid of incineration fly ash after pretreatment - The initial concentration is 31.13g / L, the content of seven heavy metals Zn, Pb, Cu, Mn, As, Cr, and Cd is 15.82mg / L, and the Cl in the washing solution in the anode chamber at the end of electrolysis - Concentration is 2.18g / L, reactor Cl - The removal rate reaches 93.00%, the heavy metal content is 6.37mg / L, and the heavy metal removal rate reaches 60%; the concentration of lye produced in the cathode chamber is 12.82g / L; Cl 2 The absorption rate is over 90%.

Embodiment 2

[0041] The reactor is the same as in Example 1, and a constant current of 0.2A is passed into the electrolytic cell, and the residence time is 3.5h. Cl in the washing liquid of incineration fly ash after pretreatment - The initial concentration is 31.13g / L, the content of seven heavy metals Zn, Pb, Cu, Mn, As, Cr, and Cd is 15.82mg / L, and the Cl in the washing solution in the anode chamber at the end of electrolysis - Concentration is 2.08g / L, reactor Cl - The removal rate reaches 93.32%, the heavy metal content is 5.96mg / L, and the heavy metal removal rate reaches 62.30%; the concentration of lye produced in the cathode chamber is 13.86g / L; Cl 2 The absorption rate is over 90%.

Embodiment 3

[0043] The reactor is the same as in Example 1, and a constant current of 0.2A is passed into the electrolytic cell for a residence time of 4h. Cl in the washing liquid of incineration fly ash after pretreatment - The initial concentration is 31.13g / L, and the seven heavy metal contents of Zn, Pb, Cu, Mn, As, Cr, and Cd are 15.82mg / L. At the end of electrolysis, Cl in the washing solution in the anode chamber - Concentration is 2.02g / L, reactor Cl - The removal rate reaches 93.51%, the heavy metal content is 5.62mg / L, and the heavy metal removal rate reaches 64.50%; the concentration of lye produced in the cathode chamber is 14.92g / L; Cl 2 The absorption rate is over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com