Production process of sodium dodecyl diphenyl ether disulfonate

A technology of dodecyl diphenyl ether and sodium disulfonate, which is applied in sulfonate preparation, organic chemistry, etc., can solve problems such as weak sulfite sulfonation ability, high environmental protection pressure, and environmental pollution, and achieve Strong sulfonation ability, fast sulfonation reaction, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

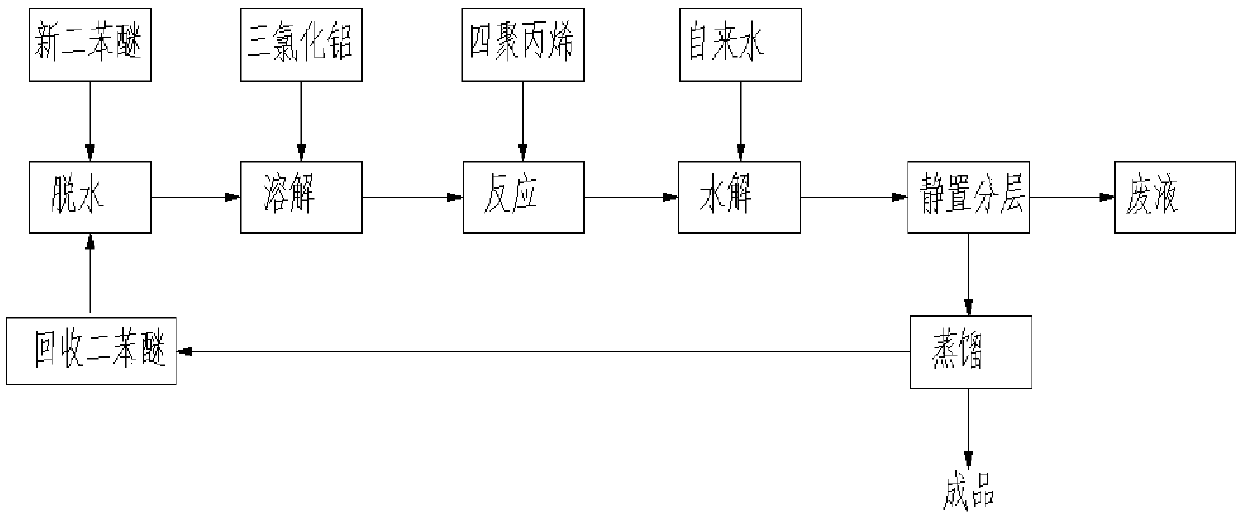

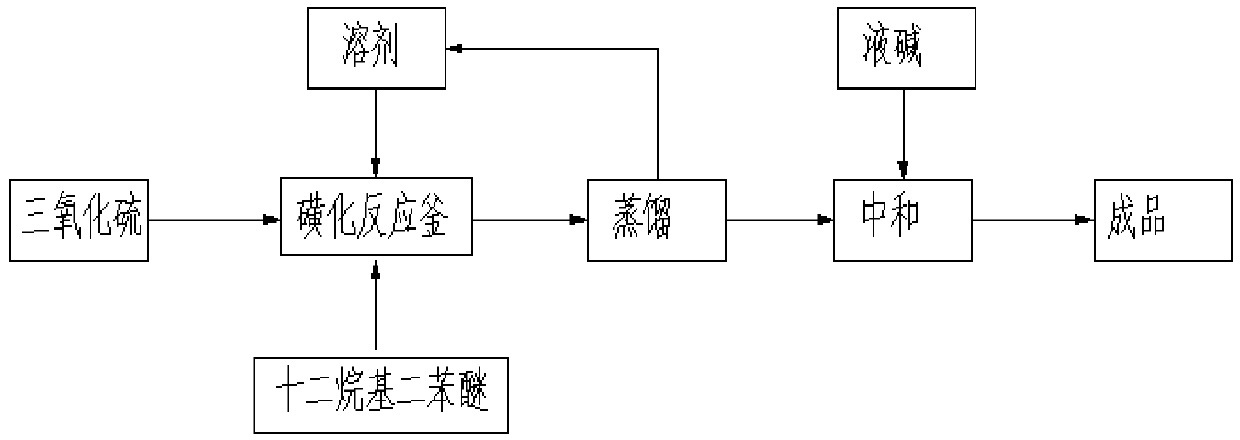

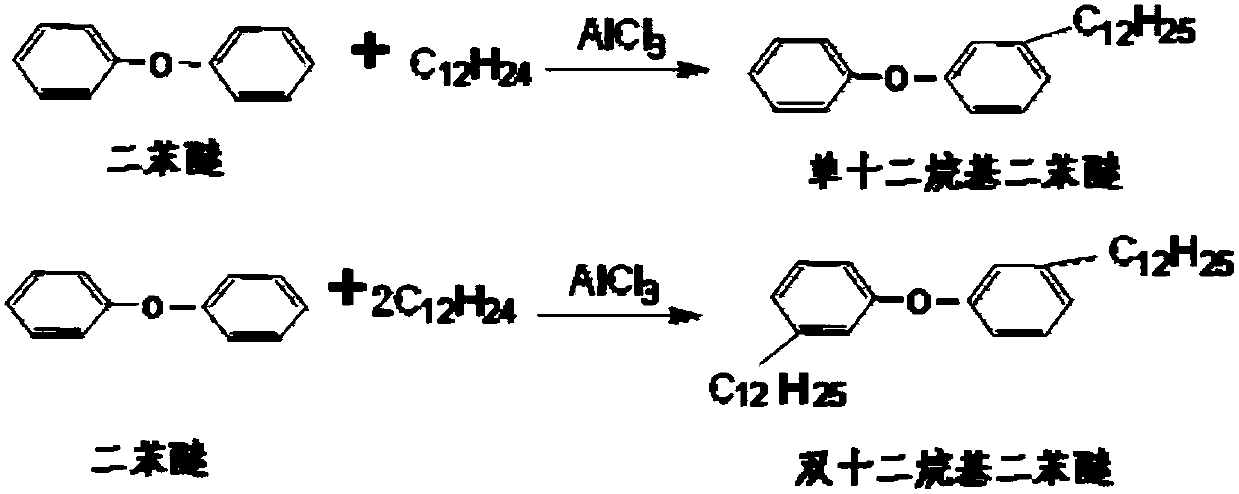

[0026] Such as figure 1 with figure 2 Shown, the production technique of a kind of sodium dodecyl diphenyl ether disulfonate of the present invention comprises the following steps:

[0027] 1) Add the measured new diphenyl ether and recovered diphenyl ether into the reactor, start the reactor to stir, start the vacuum pump, evacuate the reactor, open the jacket steam of the reactor, heat up to 80-100°C, dehydrate ;

[0028] 2) After the water content of diphenyl ether in the reaction kettle is qualified, stop the vacuum; add a certain amount of catalyst into the reaction kettle, and continue stirring until the catalyst is completely dissolved;

[0029] 3) Cool down to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com