Method for preparing 9-(4-sulfophenyl) octadecanoic acid or 10-(4-sulfophenyl) octadecanoic acid

A technology of phenyloctadecanoic acid and octadecanoic acid, applied in the preparation of sulfonic acid, organic chemistry and other directions, can solve the problems of reduced acidity, high price of chlorosulfonic acid, unfavorable reaction, etc., and achieves complete reaction, strong sulfonation ability, monolithic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

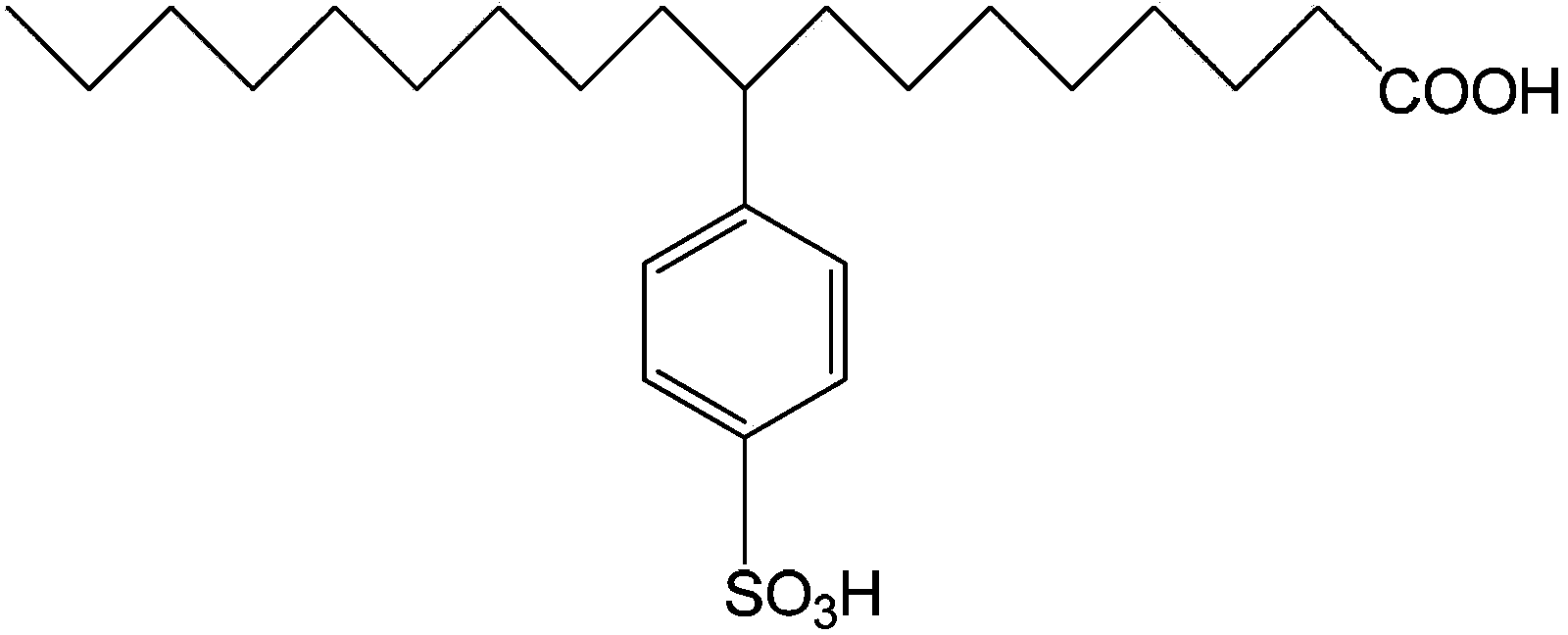

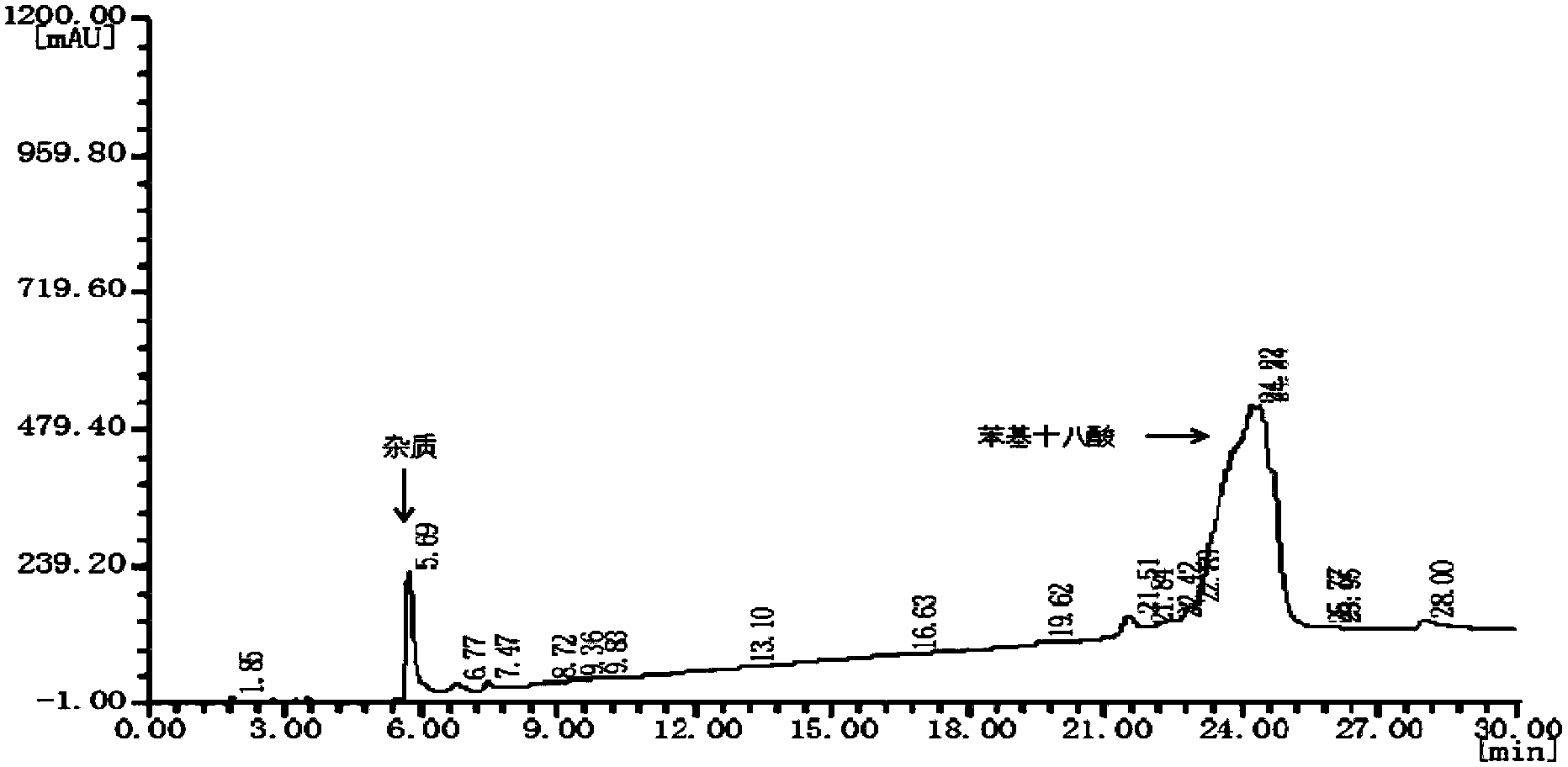

[0028] In 50 mL of a methylene chloride organic solvent solution with a concentration of 0.2 mol / L 9-phenyl octadecanoic acid, pass SO while stirring in an ice salt bath 3 Gas 0.01mol (molar ratio 1:1). React at 20°C for 2h. After the completion of the reaction, the obtained reaction liquid was rotary evaporated to remove the solvent, and extracted with a mixed solvent of ethanol and water. After the solvent was removed, 9-(4-sulfobenzene)octadecanoic acid was obtained with a yield of 90.36%. The molecular structure diagram of 9-(4-sulfobenzene) octadecanoic acid is as follows figure 1 Shown.

Embodiment 2

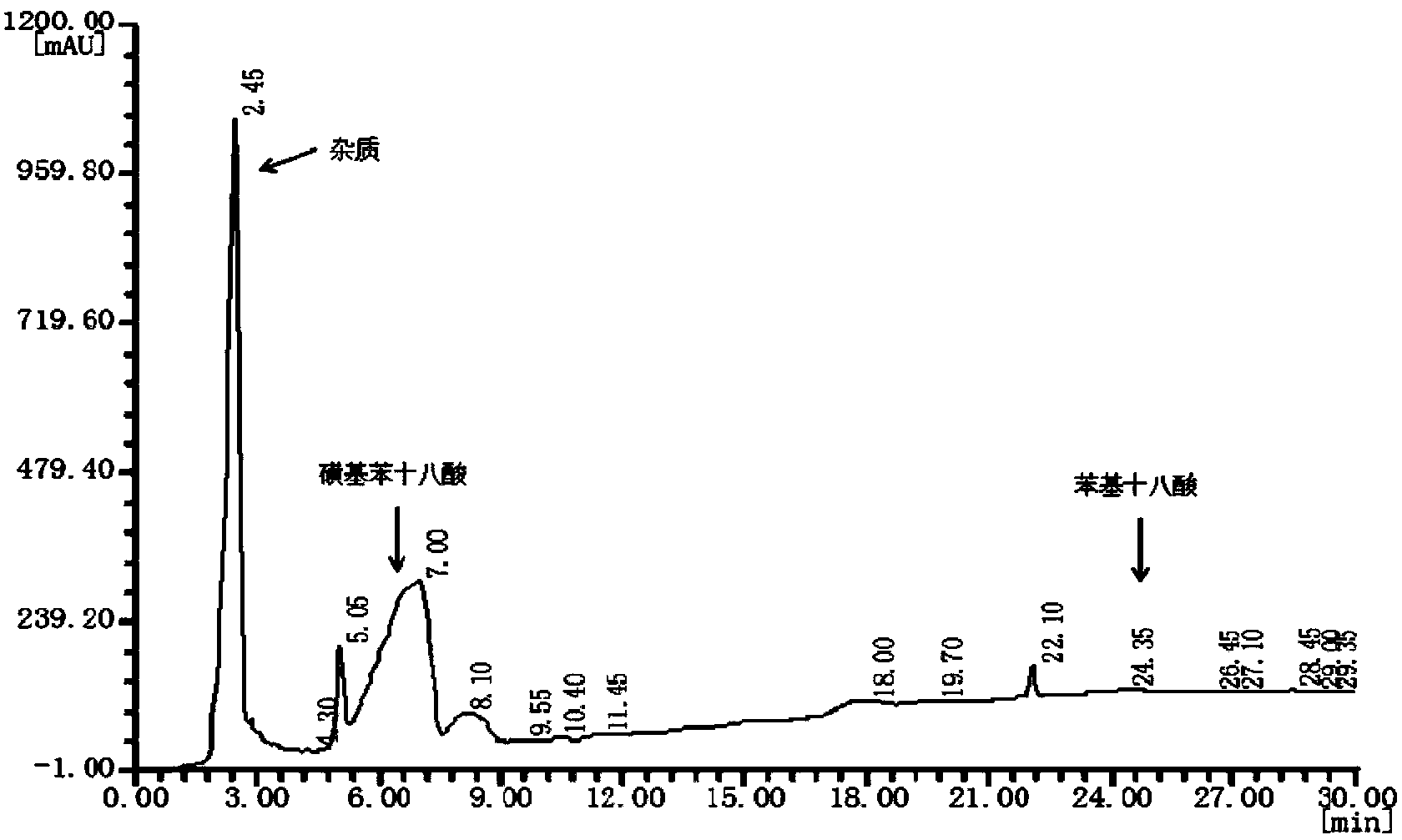

[0030] In 50 mL of a chloroform organic solvent solution with a concentration of 0.2mol / L 10-phenyloctadecanoic acid, pass SO while stirring in an ice salt bath 3 Gas 0.015mol (molar ratio 1:1.5). React at 20°C for 4h. After the completion of the reaction, the obtained reaction liquid was rotary evaporated to remove the solvent, and extracted with a mixed solvent of methanol and water. After the solvent was removed, 10-(4-sulfobenzene)octadecanoic acid was obtained with a yield of 91.77%.

Embodiment 3

[0032] In 50 mL of a chloroform organic solvent solution with a concentration of 0.2 mol / L 9-phenyl octadecanoic acid, 0.02 mol of SO3 gas (molar ratio 1:2) was introduced while stirring in an ice salt bath. React at 20°C for 6h. After the completion of the reaction, the obtained reaction liquid was rotary evaporated to remove the solvent, and extracted with a mixed solvent of methanol and water. After removing the solvent, 9 or 10-(4-sulfobenzene)octadecanoic acid was obtained, and the yield was 92.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com