Intelligent machine for petroleum drilling and mining

A technology of intelligent machinery and oil drilling, applied in the direction of earthwork drilling, drilling tools, drill pipes, etc., can solve the problems of unstable rotation of drill pipes, cost expenditure, increased labor, etc., to achieve less manual labor, increase Recovery efficiency and the effect of improving ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

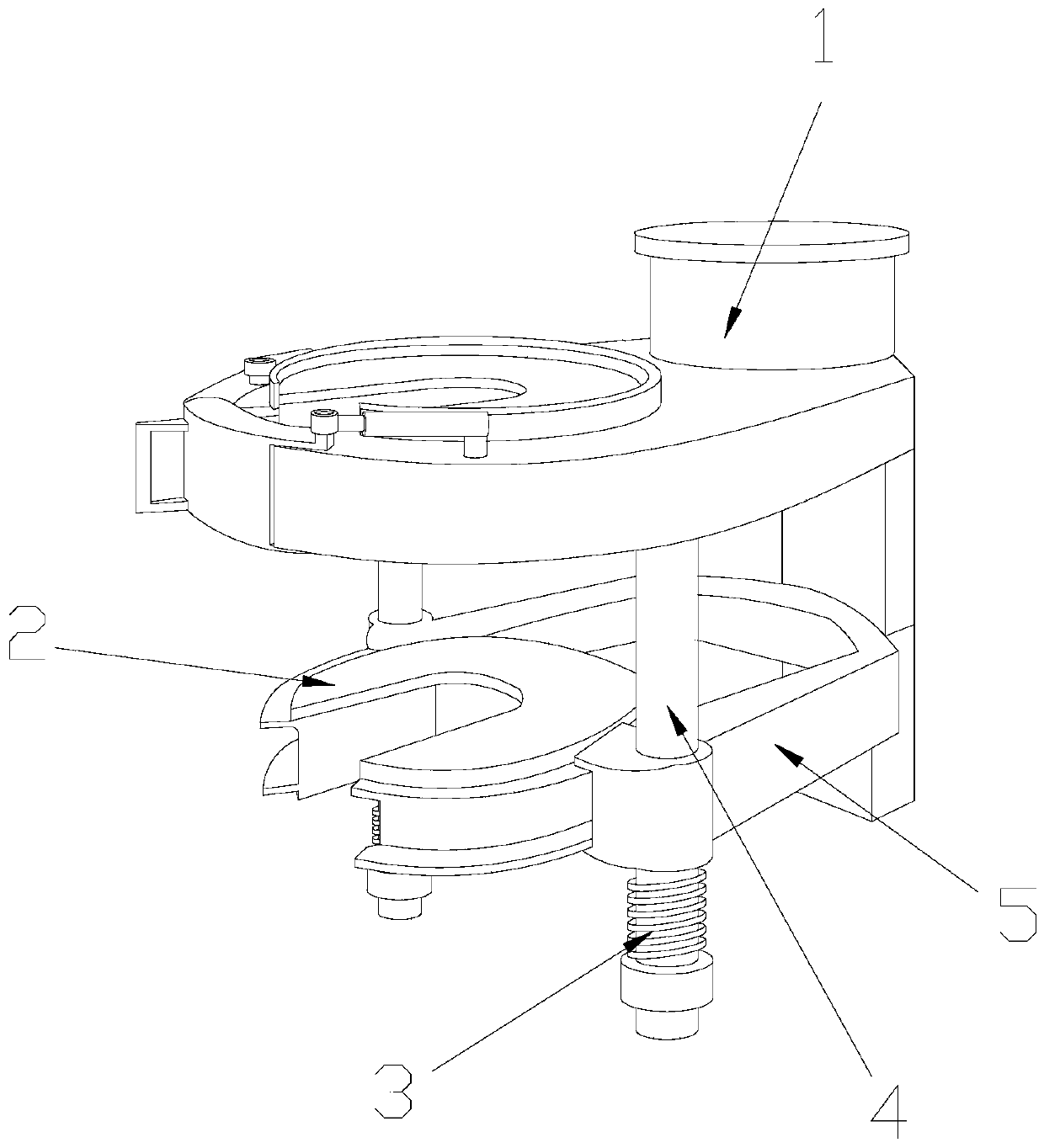

[0031] see Figure 1-Figure 5 , the present invention provides an intelligent machine for petroleum drilling, the structure of which includes a drill pipe stabilization device 1, an auxiliary gripper 2, a shock absorber 3, a support column 4, and a support frame 5. The bottom end of the drill pipe stabilization device 1 is A support frame 5 is provided, the drill pipe stabilizing device 1 is connected with the support frame 5, a support column 4 is installed between the described drill pipe stabilization device 1 and the support frame 5, and the bottom end of the support column 4 is A shock absorber 3 is provided, and the support column 4 is matched with the shock absorber 3;

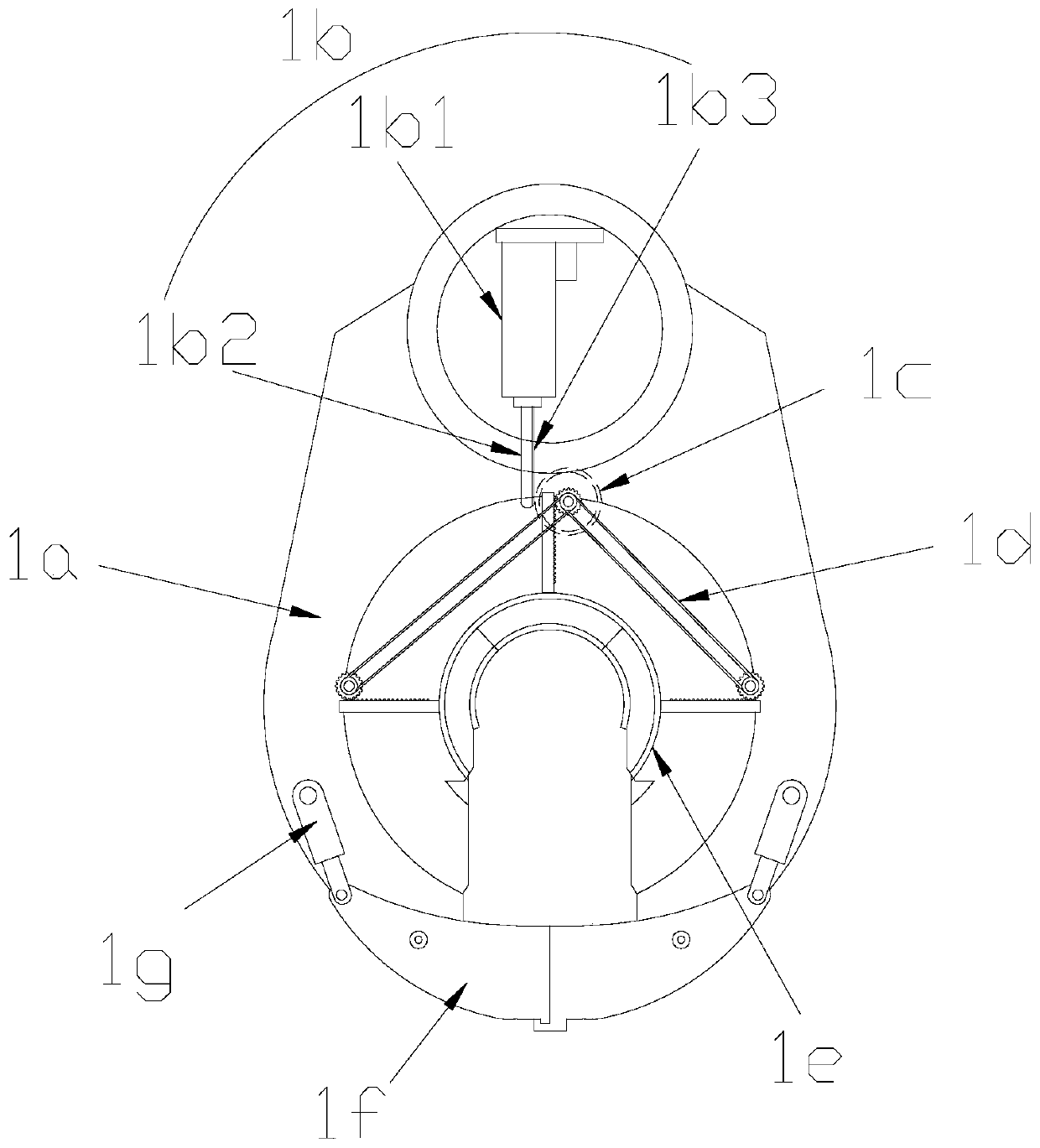

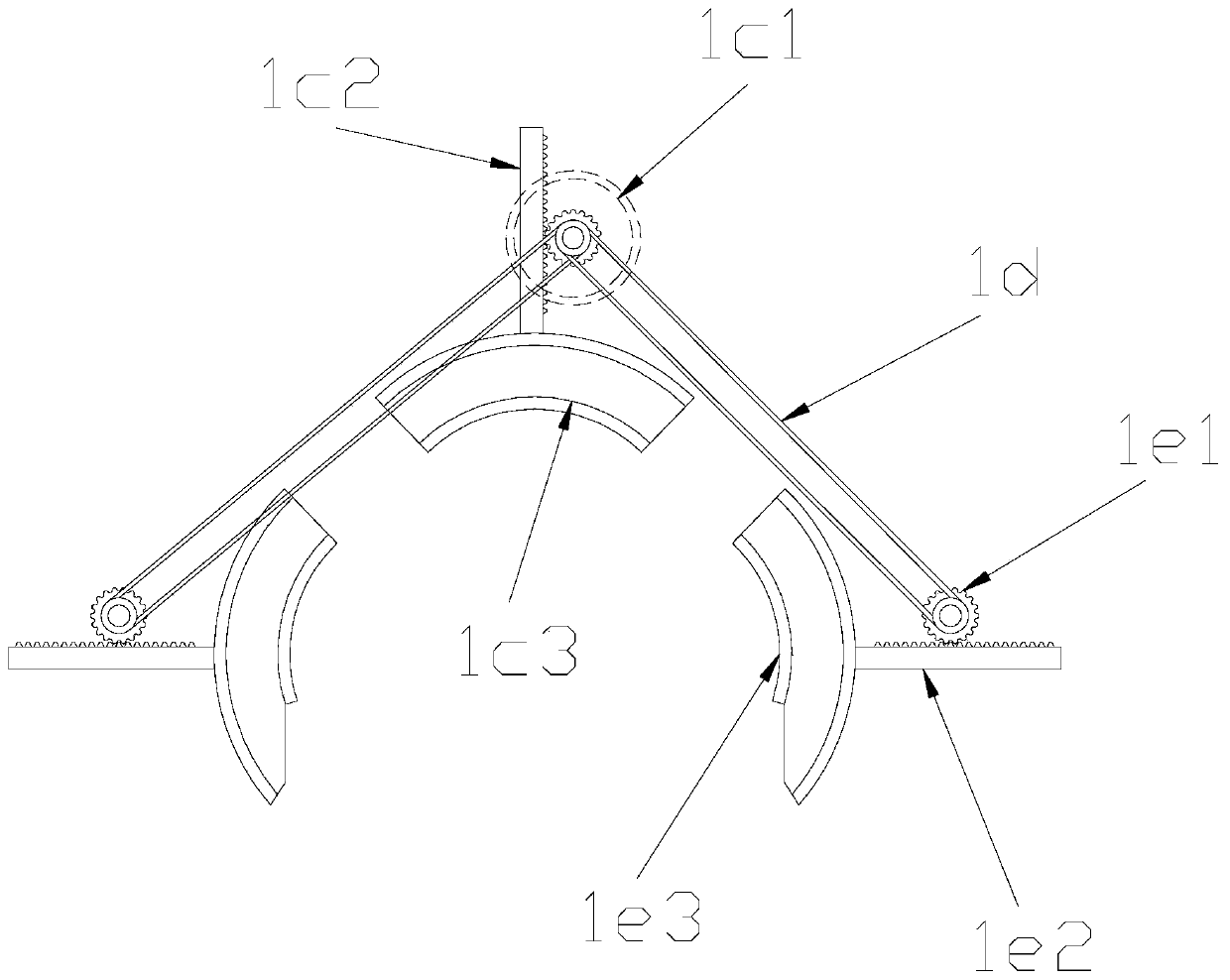

[0032] The drill pipe stabilizing device 1 is composed of a body 1a, a driving mechanism 1b, a linkage mechanism 1c, a transmission belt 1d, a turnbuckle mechanism 1e, a closing cover 1f, and a small hydraulic cylinder 1g. The front end of the body 1a is provided with two The closed cover 1f, the body ...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides an intelligent machine for oil drilling. The auxiliary clamp 2 is composed of a clamp body 2a, a spray head 2b, and a cleaning mechanism 2c. More than two spray nozzles are installed on the inner side of the clamp body 2a. The head 2b is provided with a cleaning mechanism 2c under the inner bottom end of the clip body 2a, and the clip body 2a and the cleaning mechanism 2c are slidably matched.

[0042] The cleaning mechanism 2c is composed of a slide block 2c1, a support shaft 2c2, a thread cleaning knife 2c3, and a locking rod 2c4. The inside of the slide block 2c1 is provided with a support shaft 2c2, and the slide block 2c1 and the support shaft 2c2 are fixed connection, the surface of the support shaft 2c2 is provided with a thread cleaning knife 2c3, the support shaft 2c2 and the thread cleaning knife 2c3 adopt clearance fit, the bottom of the slider 2c1 is provided with a locking lever 2c4, and the The slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com