Smoke abatement cooling device

A cooling device and smoke elimination technology, which is applied in the direction of noise reduction device, exhaust device, gas treatment, etc., can solve the problems that cannot meet the requirements of the country's concealed military facilities, and achieve the effect of reducing the concentration of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

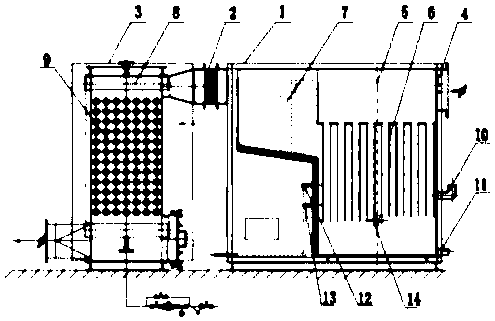

[0013] A smoke extinguishing and cooling device, comprising a primary smoke extinguishing and cooling device 1, a secondary smoke extinguishing and cooling device 2, and a flange 3, wherein the primary smoke extinguishing and cooling device 1 and the secondary smoke extinguishing and cooling device 2 pass through the flange 3 It is connected; it is characterized in that: the first-stage smoke elimination and cooling device 1 includes a smoke inlet 4, a smoke elimination and cooling chamber 5, a jet bubbling reactor 6 and a filter screen 7; the smoke elimination and cooling chamber 5 is set on the right side There is a smoke inlet 4, a jet bubbling reactor 6 is provided below, and a multi-layer filter screen 7 is provided on the left; the secondary cooling device 2 includes a flow equalization chamber 8 and a secondary cooling spiral finned tube cooler 9 , the flow equalization chamber 8 is set above the secondary smoke elimination and cooling device 2, and several secondary coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com