Novel true triaxial fracturing seepage test device and method

A test device and fracturing test technology, applied in the direction of measuring device, applying stable tension/pressure to test material strength, permeability/surface area analysis, etc., can solve the problem that porous rock specimens with pore pressure cannot be fractured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

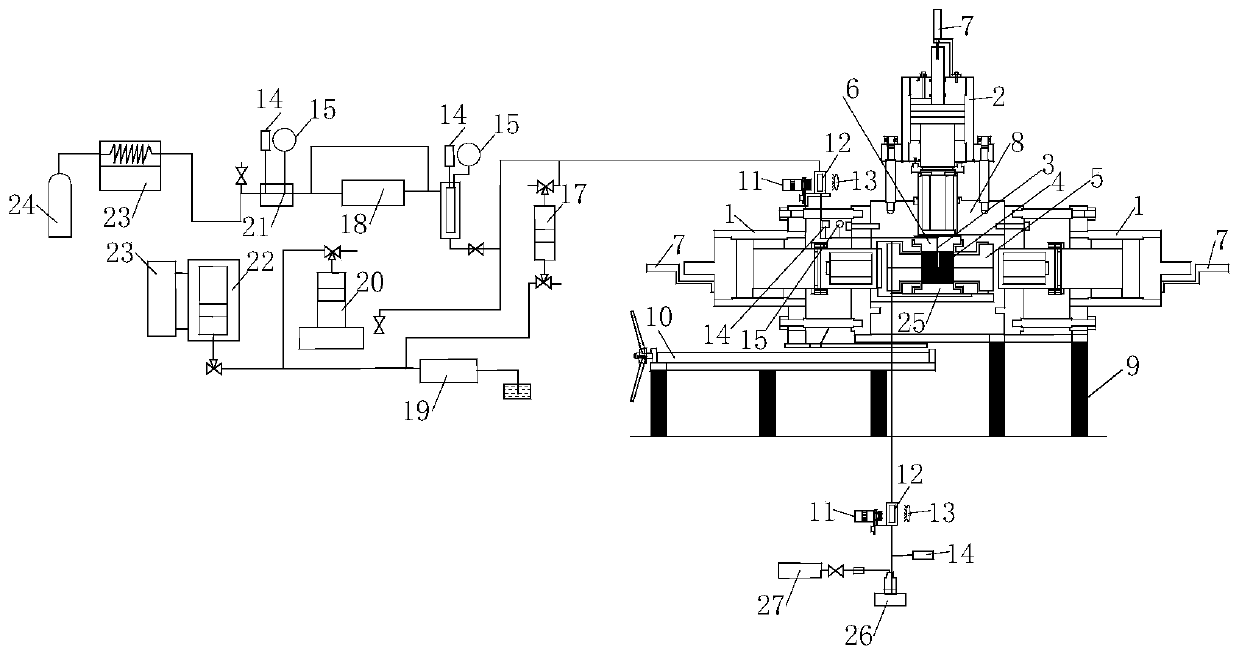

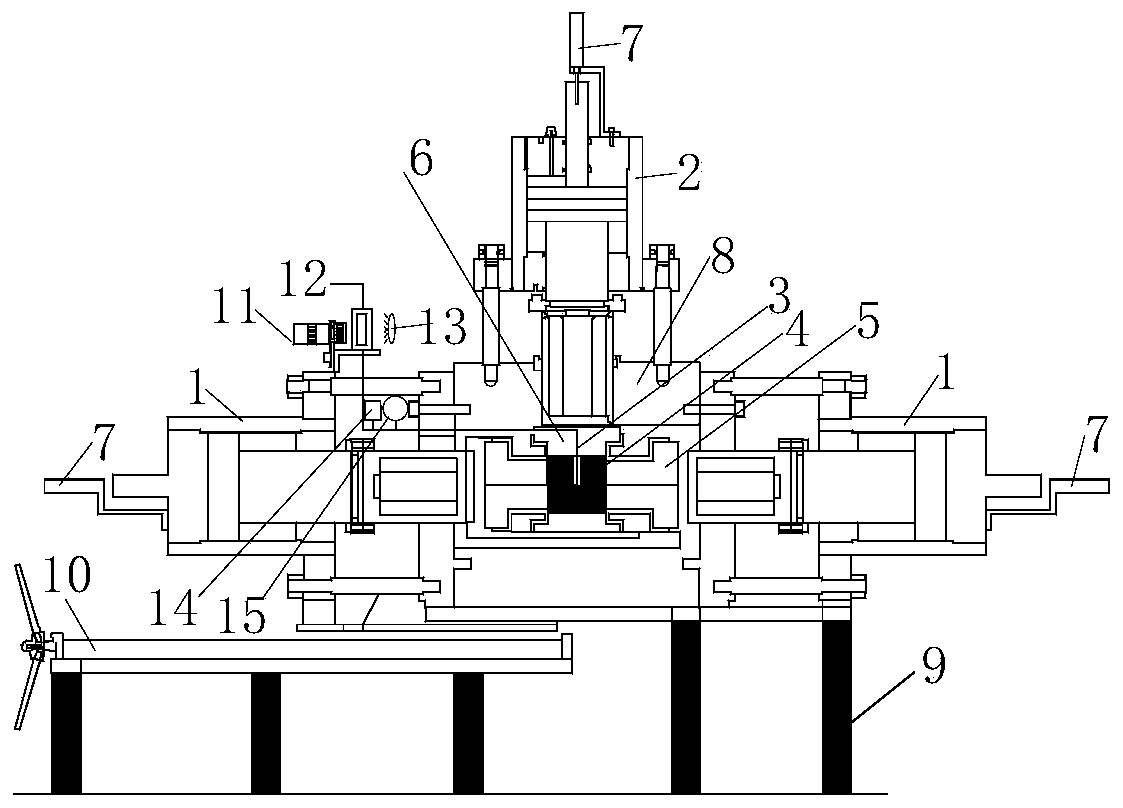

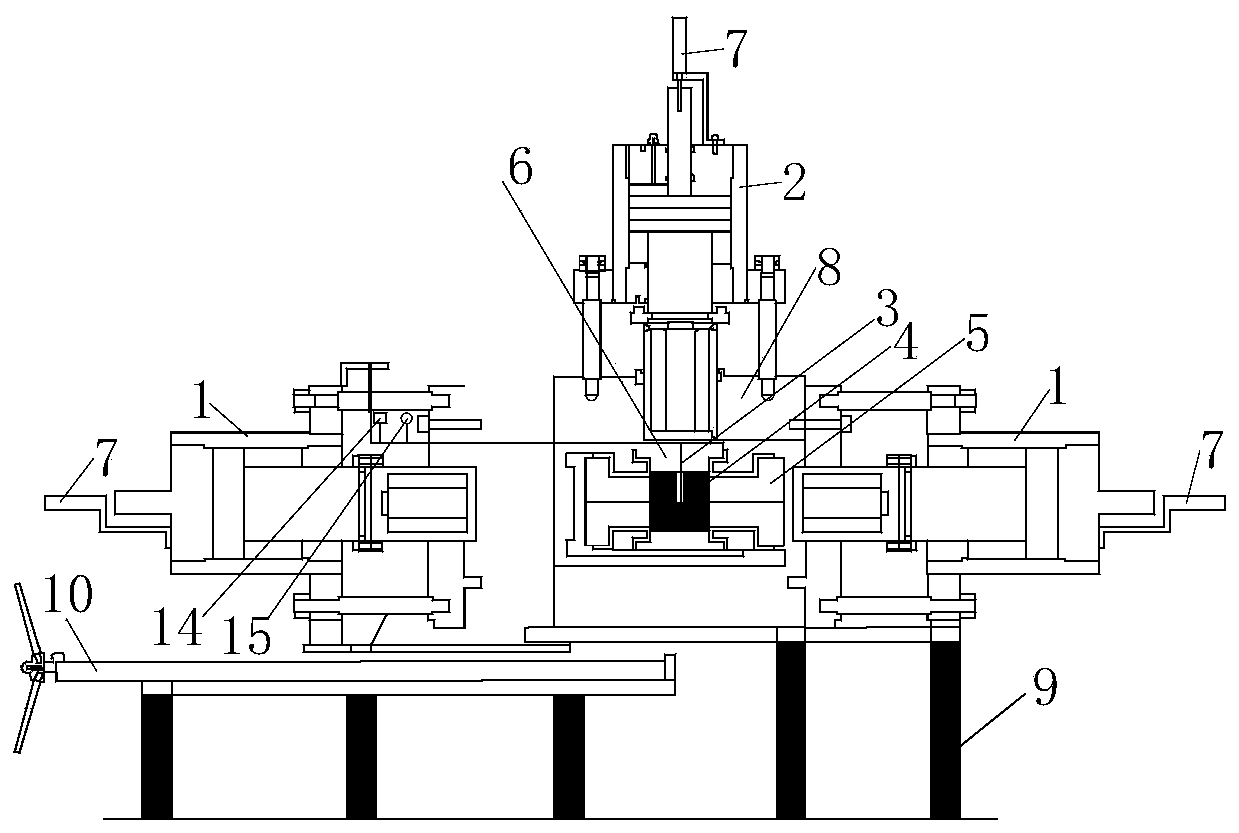

[0034] In the above-mentioned new true triaxial fracturing seepage test device and method, the device first removes the built-in fracturing cavity as a whole through the manual rocker, and puts the cube test piece saturated with the fluid that has been drilled into the fracturing wellbore into the fracturing chamber. Then put the test piece inside the fracturing cavity, and move the test piece into the pressure chamber of the fracturing overall frame by the manual rocker; secondly, arrange the pressure sensor in the pressure pipeline and the temperature sensor in the fracturing chamber. crack the bottom of the wellbore, and measure the working state of the instrument to ensure the operating state of the instrument; place the porous loading steel plate between the built-in oil cylinder and the test piece, and arrange 8 acoustic emission probes to be placed on the edge of the test piece respectively, and through the external The oil cylinder applies load step by step, and then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com