Multidimensional data anomaly detection method and device based on XGBoost

A multi-dimensional data and anomaly detection technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as low accuracy and slow speed of multi-dimensional data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

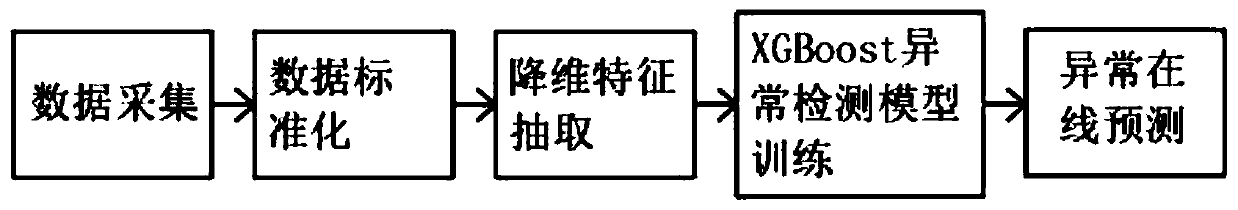

[0057] Such as figure 1 As shown, the multidimensional data anomaly detection method based on XGBoost includes:

[0058] Step 1: Data collection and cleaning. Most of the original multi-dimensional data comes from real-time data collected by thermal power plant equipment sensors. Due to the long-term deterioration of sensors or the influence of noise in the data transmission process, there may be some obvious differences in the original data that are measured by the sensors. Values outside the range are either directly implemented as 0 or null. Such data (referred to as interference value in the present embodiment) cannot explain that the operation of the equipment is in an abnormal state, and when such data is input into the abnormal detection system for abnormal detection, it will often bring false positive results. Therefore, after obtaining the original data, it is necessary to perform preprocessing on the original data to remove these interference values.

[0059] 1-...

Embodiment 2

[0092] A detection device installed with the above method, including a memory, a processor, an I / O device and an alarm device that are electrically connected and stored with a program for realizing the above method, and the I / O device is connected to a computer and / or network that installs the monitoring software of the power plant, Access and obtain real-time measurement point data.

[0093] The processor is connected to the hand-held user terminal through wireless transmission. Remote monitoring and early warning through handheld devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com