Powder processing device

A processing device and powder technology, applied in grain processing and other directions, to achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

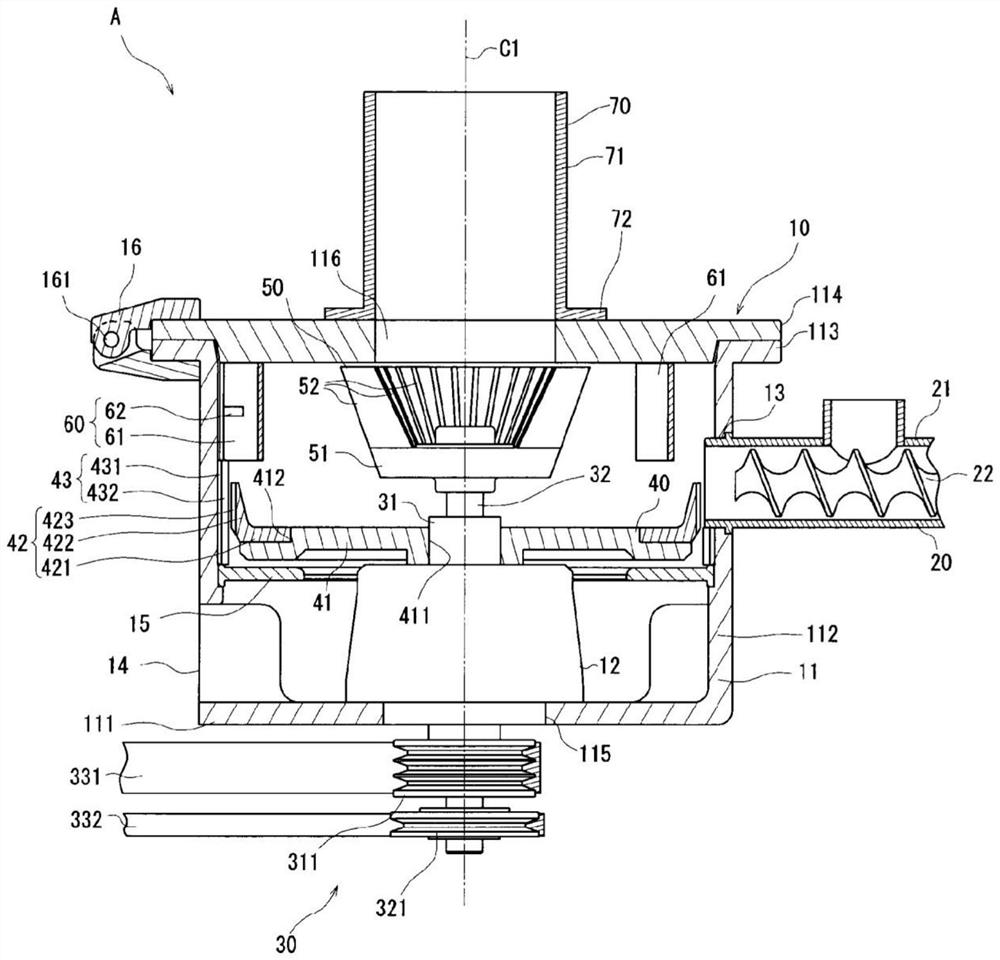

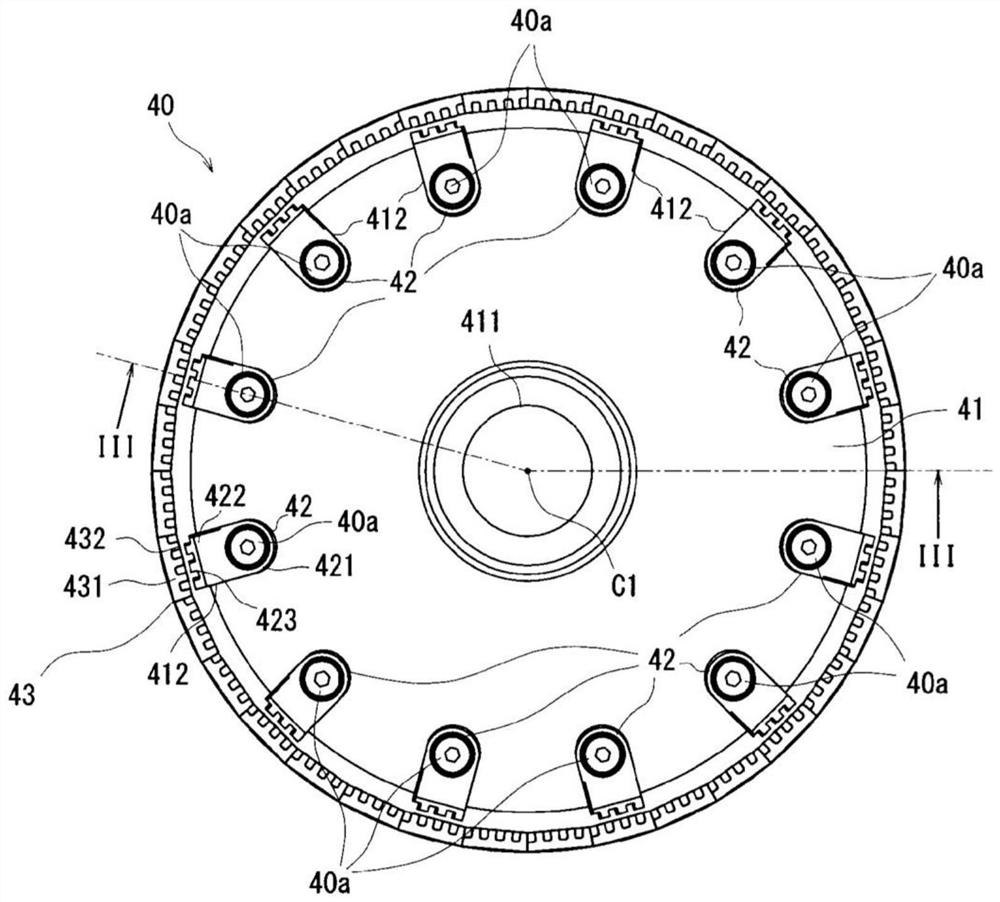

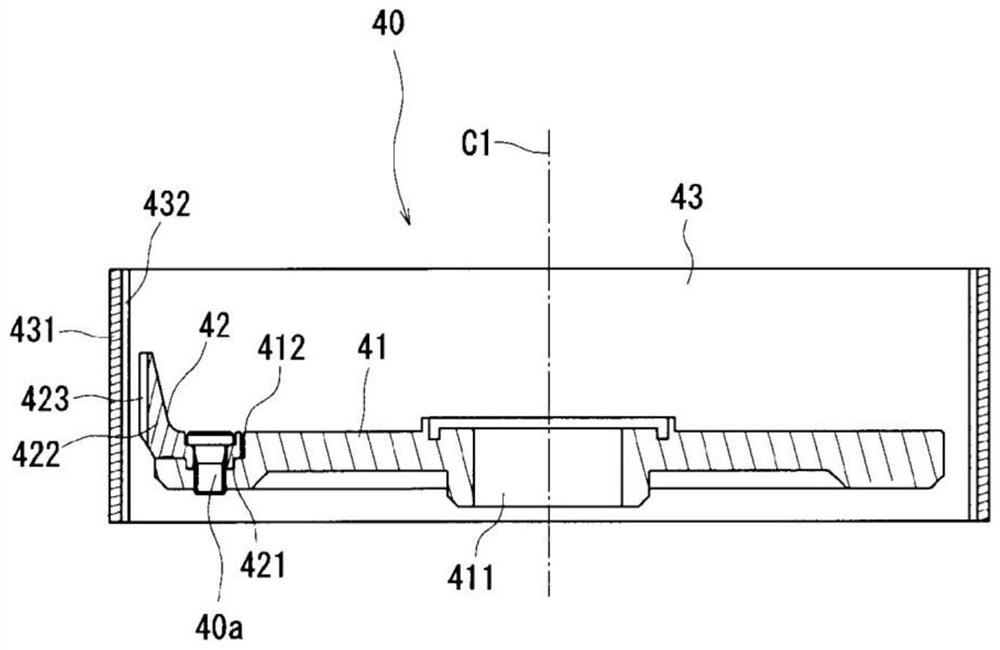

[0037] The powder processing apparatus according to the present invention will be described with reference to the drawings.

[0038]

[0039] figure 1 It is a cross-sectional view of the powder processing device according to the present invention. The powder processing device A crushes the bulk material into powder or granules. Such as figure 1 As shown, the powder processing apparatus A includes a frame body 10 , a raw material supply unit 20 , a drive unit 30 , a pulverization unit 40 , a swirling air flow generation unit 50 , a guide unit 60 and an air flow outflow unit 70 . In addition, let the direction in which the central axis C1 extends be an up-down direction. The direction perpendicular to the up-down direction is defined as a radial direction, the side toward the center is defined as the inner side, and the side away from the center is defined as the outer side. In addition, let the direction along the circumference centered on the central axis C1 be the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com