Plate-type flame arrester with wavy micro-channels

A wave-shaped, micro-channel technology, applied in fire rescue and other directions, can solve the problems of prolonged cleaning cycle, easy deposition of ash, large fluid resistance, etc., and achieve the effect of prolonged cleaning cycle, good fire resistance and low fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

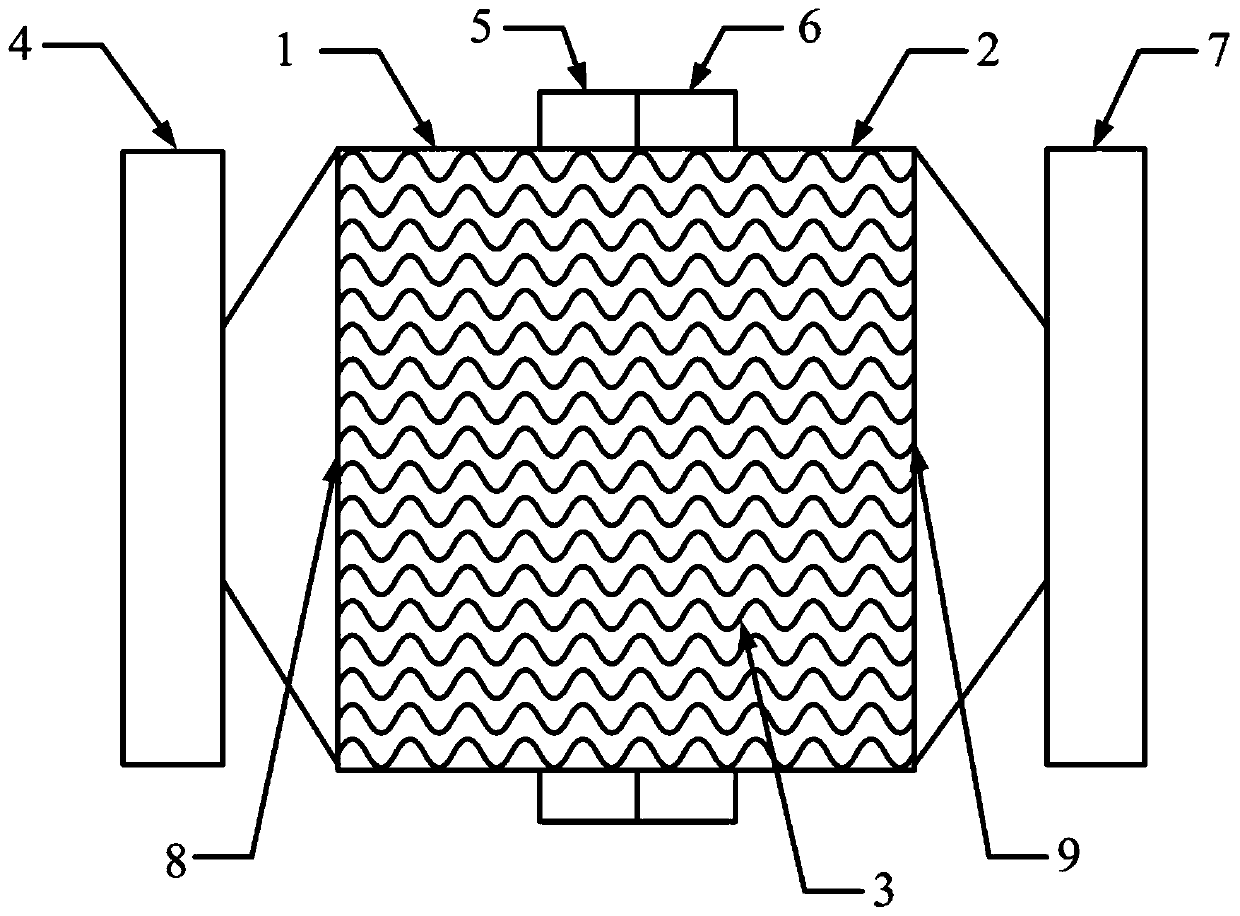

[0017] Such as Figures 1 to 2 As shown, a plate flame arrester with corrugated microchannels includes a cylinder and a fire arresting core 3. The cylinder includes a first cylinder 1 and a second cylinder 2, and the first cylinder 1 is connected by a flange II5 It is connected with flange III6, specifically, flange II5 and flange III6 are sealed and connected by bolts and nuts, and gaskets are also provided between the bolts and nuts; the other end of the first cylinder 1 is also provided with flange I4 , the other end of the second cylinder 5 is also provided with a flange IV7 for connection with the pipeline; the fire retardant core 3 is arranged in the cylinder, and the two ends of the fire retardant core 3 are respectively provided with a first support plate 8 and a second support Plate 9, the first cylinder expansion cavity is formed between flange I4 and the first support plate 8, and the second cylinder expansion cavity is formed between flange IV7 and the second suppo...

Embodiment 2

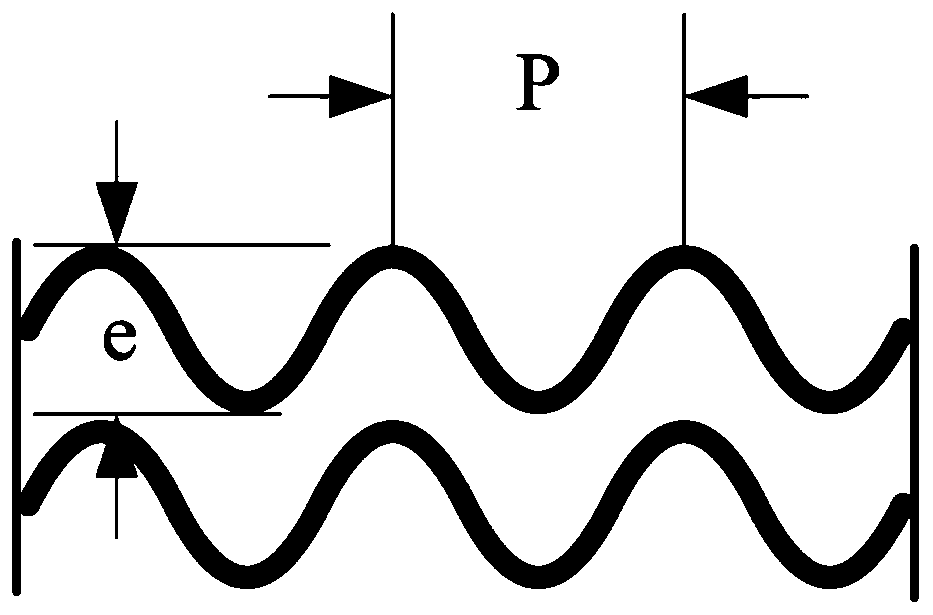

[0023] The difference from Example 1 is that in this example, the wave height e of the stainless steel plate is 1 mm, the wavelength P is 100 mm, the distance between the microchannels formed by the stainless steel plate is 20 mm, and the expansion cavity of the first cylinder and the expansion cavity of the second cylinder are The expansion angles are all 10°.

Embodiment 3

[0025] Different from Embodiment 1, in this embodiment, the wave height e of the stainless steel plate is 10mm, the wavelength P is 100mm, the distance between the microchannels formed by the stainless steel plate is 0.5mm, and the expansion chamber of the first cylinder and the expansion chamber of the second cylinder The expansion angle of the cavity is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com