Automatic laser coding machine with vacuum mechanism

A technology of laser coding machine and vacuuming mechanism, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of pollution in the operation room, human harm and other problems, and achieve the effect of reducing the offset of the coding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

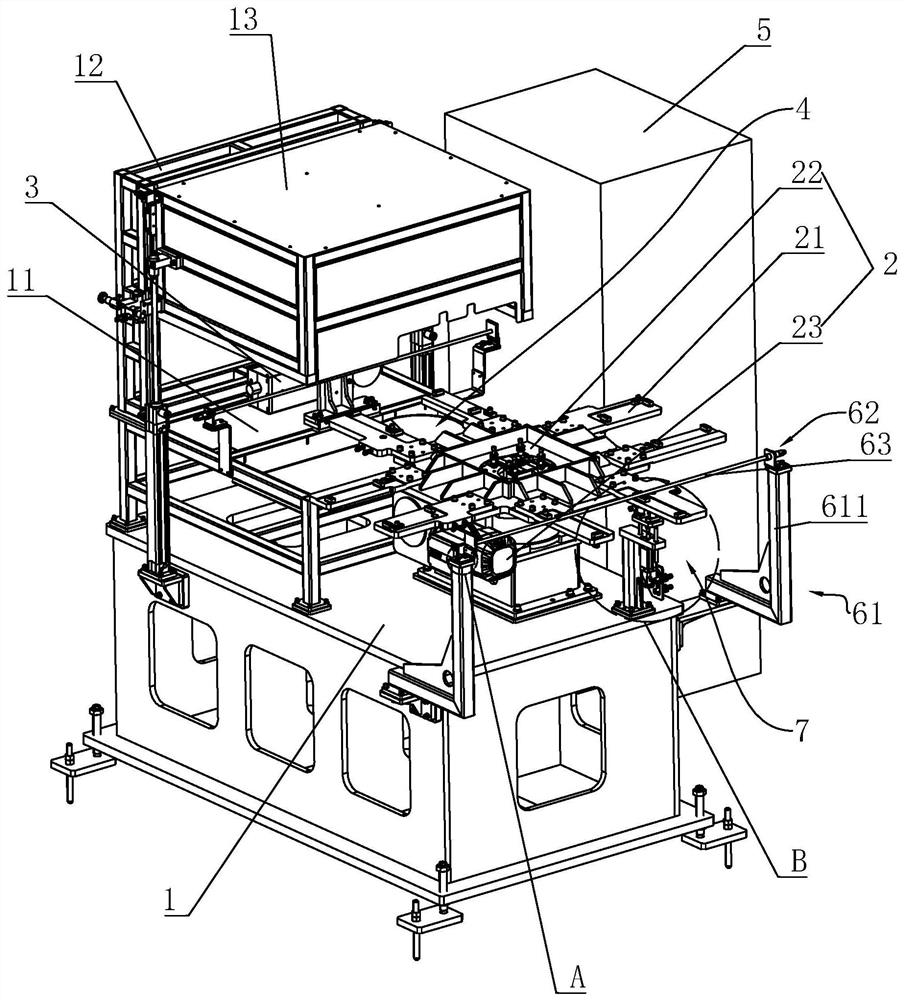

[0034] Example: refer to figure 1 , is an automatic laser marking machine with a dust suction mechanism disclosed in the present invention, including a frame 1, a discharge mechanism 2 arranged on the frame 1, a mounting seat 11 arranged on the frame 1, and a The laser coding mechanism 3 on the seat 11, the dust suction mechanism 4 and the control mechanism 5 arranged on the frame 1 side. In this embodiment, the control mechanism 5 is a control cabinet with control elements inside. During processing, the operator places and fixes the cylinder block of the automobile engine to be coded through the discharge mechanism 2, and then the laser coding mechanism 3 performs laser coding on the cylinder block of the automobile engine, and the dust collection mechanism 4 cleans the smoke generated during the coding process. Dust is suctioned, thereby reducing the possibility of smoke and dust being emitted into the air and causing air pollution.

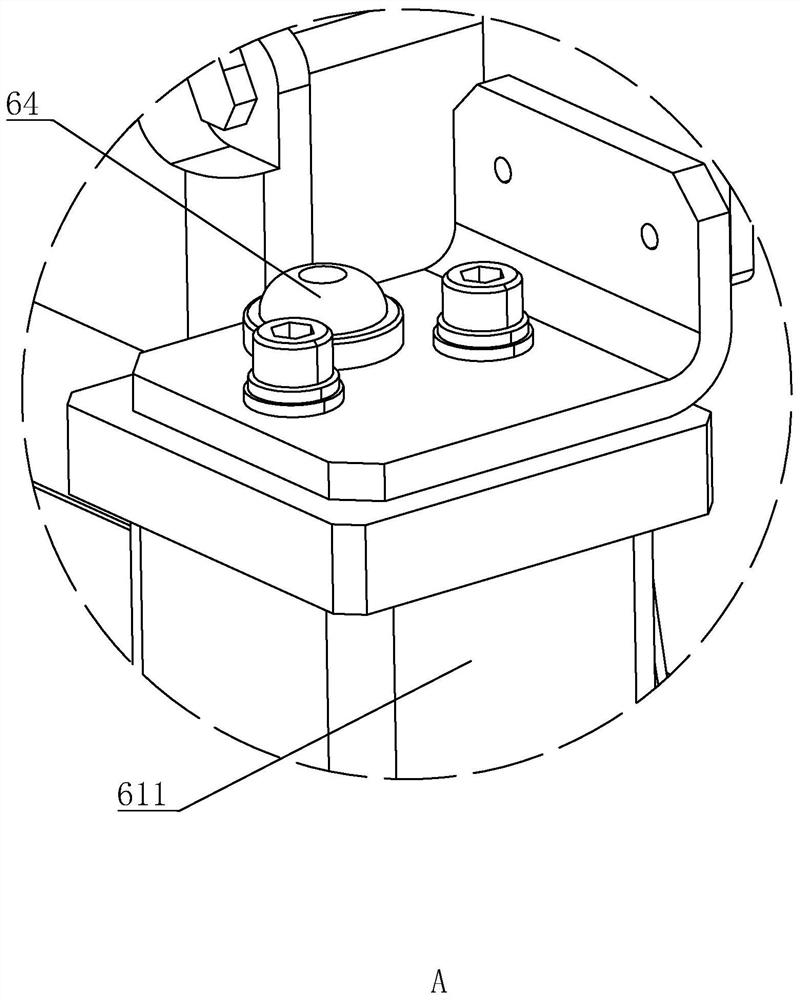

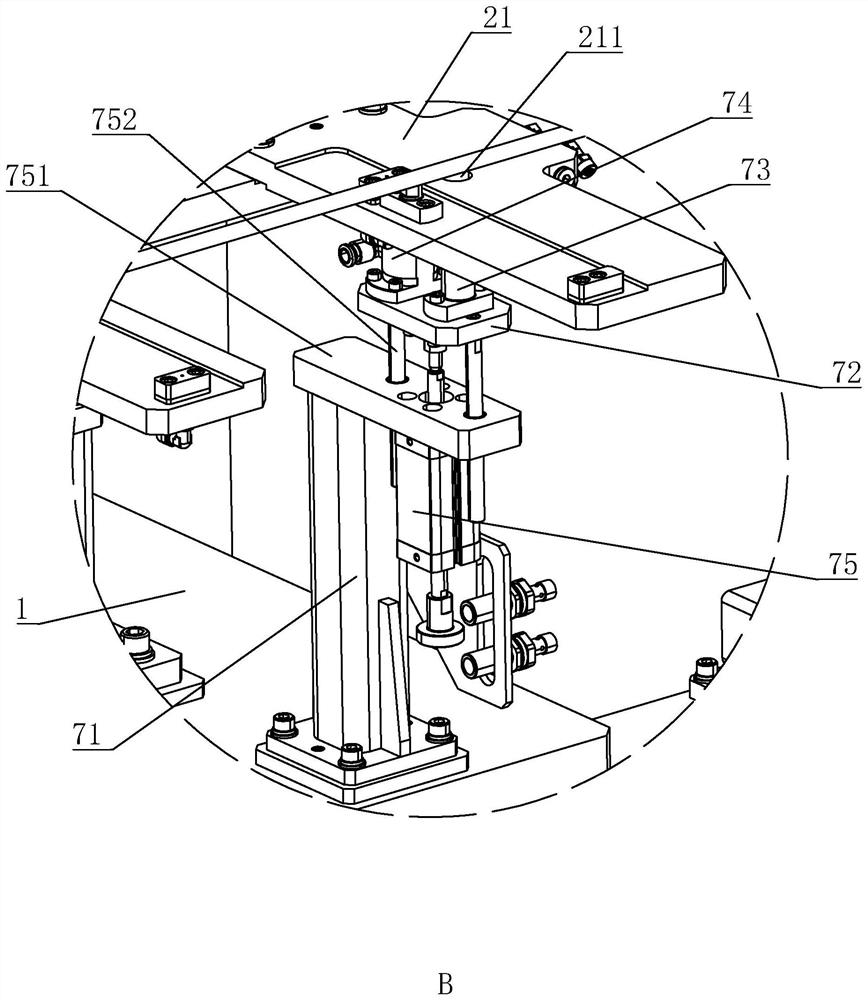

[0035] refer to figure 1 The discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com