Sandwich plate full-automatic dual-machine production line

A fully automatic, multi-layer board technology, applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of not meeting the speed requirements of billet formation, slowing down work efficiency, and low production efficiency. , to achieve the effect of simplifying the production process, reducing labor intensity and reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

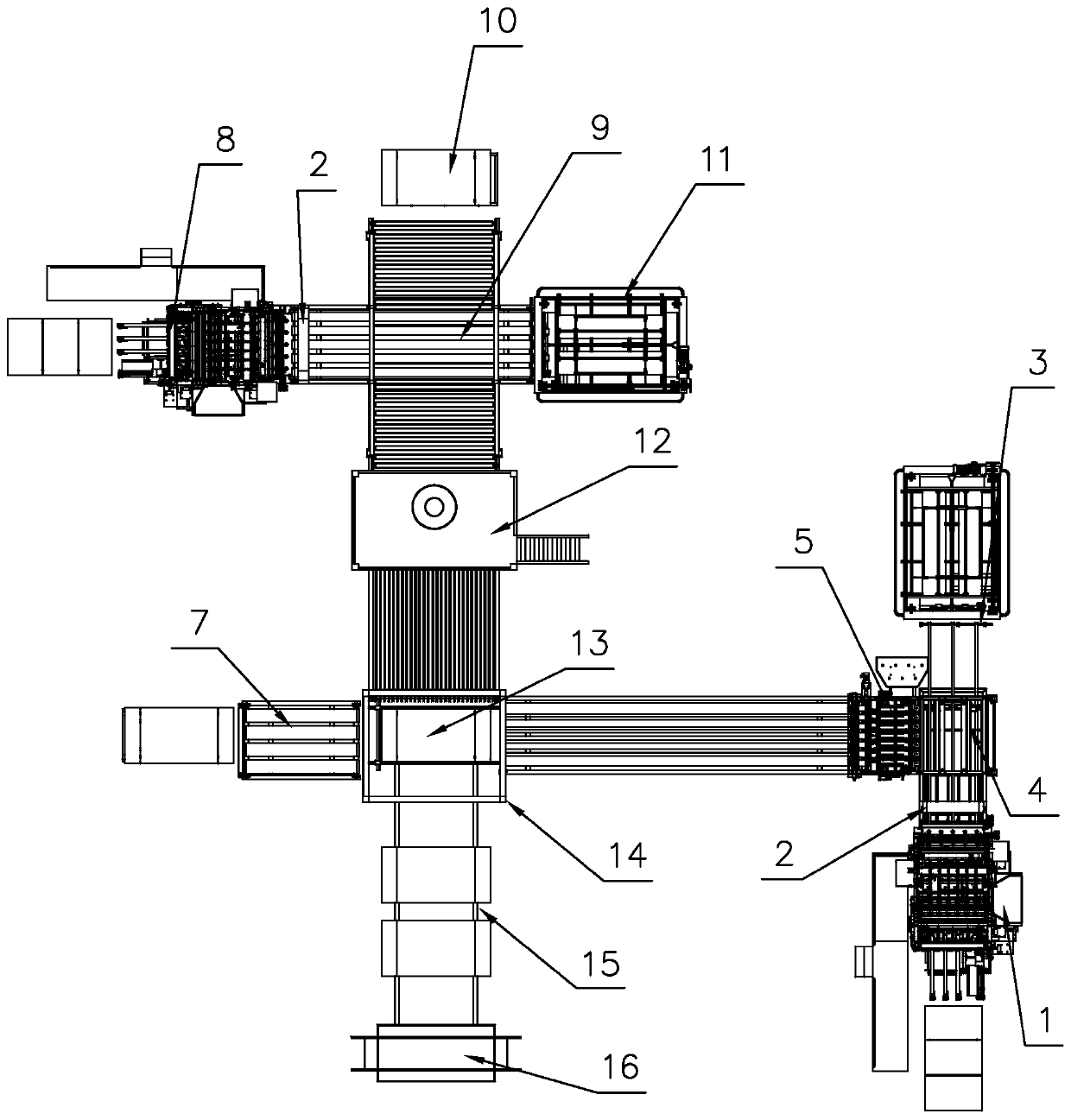

[0045] Embodiment 1, as attached figure 1 To be specific:

[0046] A fully automatic two-machine production line for multi-layer boards, including veneer I vertical splicing and horizontal splicing mechanism 1, finished product viewing angle detection mechanism 2, veneer I defective product separation mechanism 3, 90° steering mechanism I4, veneer II vertical splicing Mechanism 5, veneer II horizontal splicing mechanism 8, 90° steering mechanism II 9, veneer II defective product separation mechanism 11, veneer automatic gluing mechanism 12, rubber sheet assembly mechanism 13, palletizing mechanism 14, automatic transport mechanism 15 , Fully automatic cold pressing mechanism 16;

[0047]The veneer I vertical splicing and horizontal splicing mechanism 1 is provided with a 90° steering mechanism I4 on one side, and a finished product viewing angle detection mechanism 2 between the veneer I vertical splicing and horizontal splicing mechanism 1 and the 90° turning mechanism I4, a...

Embodiment approach 2

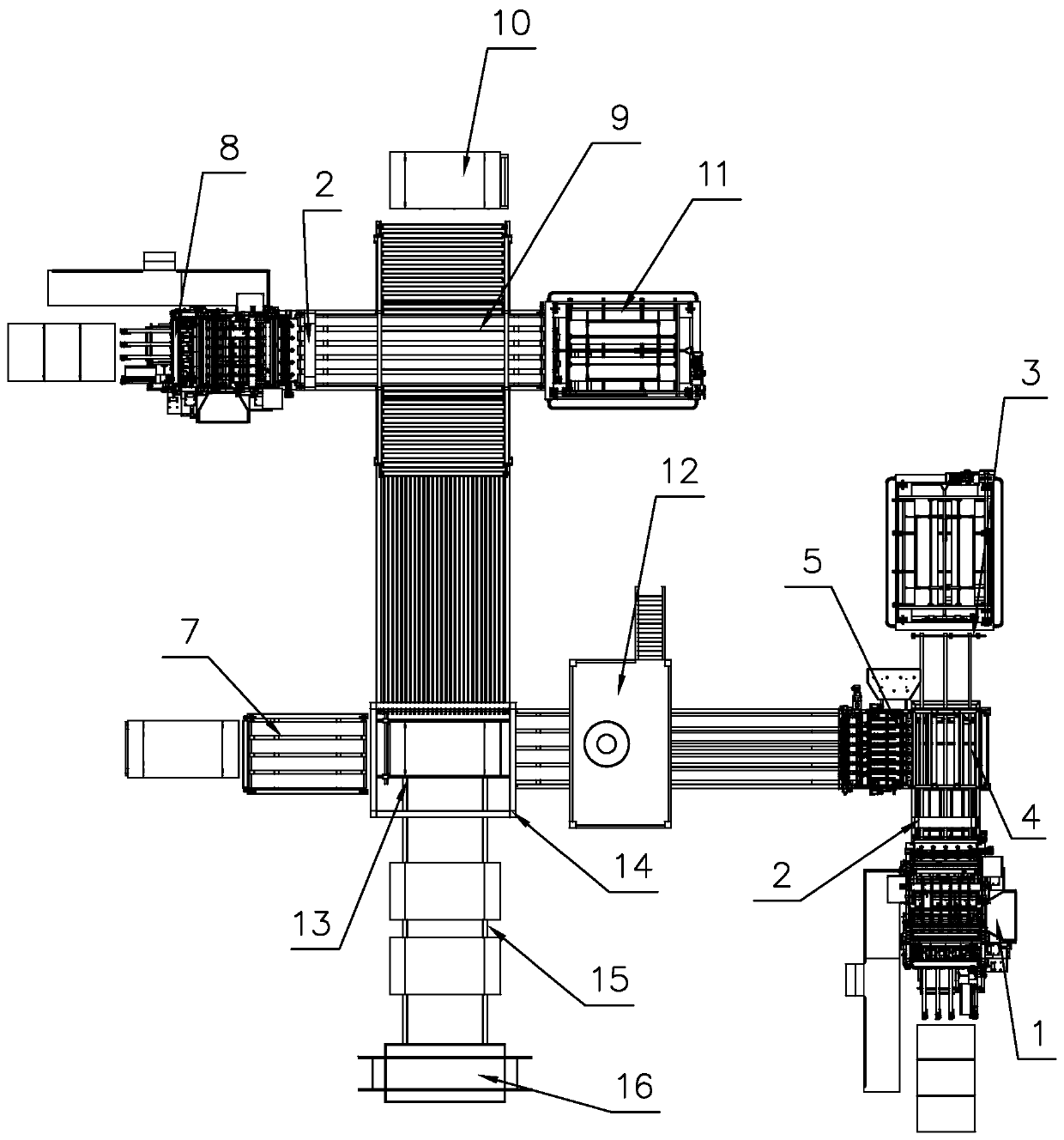

[0068] Embodiment 2, as attached figure 2 To be specific:

[0069] The difference from Example 1 is: a fully automatic two-machine production line for multi-layer boards, including veneer I vertical splicing and horizontal splicing mechanism 1, finished product viewing angle detection mechanism 2, veneer I defective product separation mechanism 3, and 90° steering Mechanism Ⅰ4, veneer II vertical splicing mechanism 5, veneer II horizontal splicing mechanism 8, 90° steering mechanism Ⅱ9, veneer II defective product separation mechanism 11, veneer automatic gluing mechanism 12, rubber sheet assembly mechanism 13, Palletizing mechanism 14, automatic transport mechanism 15, fully automatic cold pressing mechanism 16;

[0070] The veneer I vertical splicing and horizontal splicing mechanism 1 is provided with a 90° steering mechanism I4 on one side, and a finished product viewing angle detection mechanism 2 between the veneer I vertical splicing and horizontal splicing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com