Preparation method of small-size graphene quantum dots

A technology of graphene quantum dots and small size, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of large size and poor uniformity of graphene quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

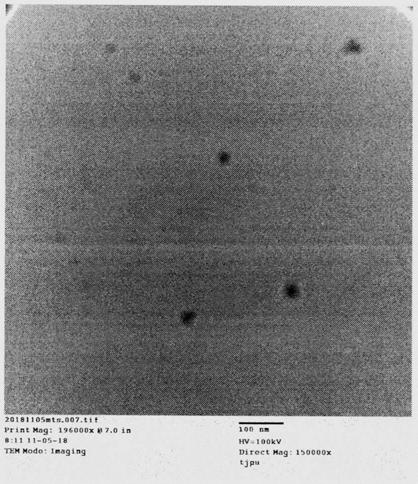

Image

Examples

Embodiment 1

[0022] (1) Weigh 500 mesh graphite and add it into deionized water to prepare an aqueous solution of graphite with a concentration of 3 mg / ml.

[0023] (2) ultrasonically disperse the graphite aqueous solution in ultrasonic equipment for 1 h. The aqueous solution of the sonicated graphite was freeze-dried in a freeze dryer to obtain dried graphite.

[0024] (3) The dried graphite is placed in a vapor deposition furnace in a nitrogen atmosphere, and the temperature is raised to 200° C. within 20 minutes and kept for 1 hour.

[0025] (4) The heat-treated graphite is irradiated with γ-rays in the air, the absorbed dose is 150KGy, and the irradiation dose rate is 2.7KGy / h to obtain the irradiated graphite.

[0026] (5) 360ml of concentrated sulfuric acid and 40ml of concentrated phosphoric acid will be taken, and the two acids will be stirred and mixed evenly. The mixed acid solution was transferred to a beaker of suitable size and placed in a water bath, heated at a constant te...

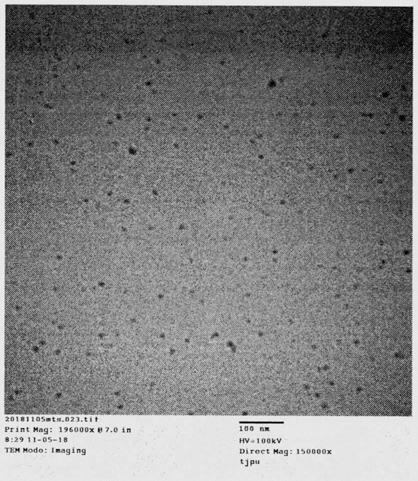

Embodiment 2

[0032] (1) Weigh 200 mesh graphite and add it to deionized water to prepare an aqueous solution of graphite with a concentration of 3 mg / ml.

[0033] (2) ultrasonically disperse the graphite aqueous solution in ultrasonic equipment for 1 h. The aqueous solution of the sonicated graphite was freeze-dried in a freeze dryer to obtain dried graphite.

[0034] (3) The dried graphite was placed in a vapor deposition furnace in a nitrogen atmosphere, and the temperature was raised to 250° C. within 30 minutes and kept for 1 hour.

[0035] (4) The heat-treated graphite is irradiated with γ-rays in the air, the absorbed dose is 150KGy, and the irradiation dose rate is 2.7KGy / h to obtain the irradiated graphite.

[0036] (5) 360ml of concentrated sulfuric acid and 40ml of concentrated phosphoric acid will be taken, and the two acids will be stirred and mixed evenly. The mixed acid solution was transferred to a beaker of suitable size and placed in a water bath, heated at a constant te...

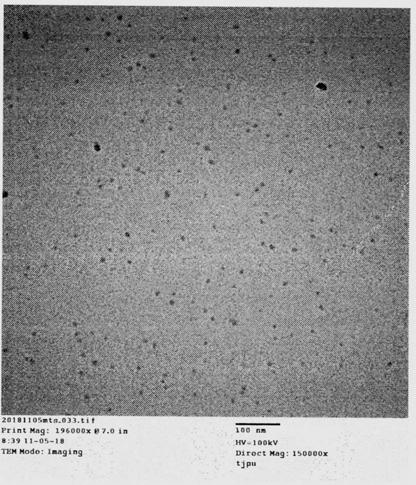

Embodiment 3

[0042] (1) Weigh 500 mesh graphite and add it to deionized water to prepare an aqueous solution of graphite with a concentration of 5 mg / ml.

[0043] (2) ultrasonically disperse the graphite aqueous solution in ultrasonic equipment for 1 h. The aqueous solution of the sonicated graphite was freeze-dried in a freeze dryer to obtain dried graphite.

[0044] (3) The dried graphite is placed in a vapor deposition furnace in an argon atmosphere, and the temperature is raised to 270° C. within 30 minutes and kept for 1 hour.

[0045] (4) The heat-treated graphite is irradiated with γ-rays in the air, the absorbed dose is 150KGy, and the irradiation dose rate is 2.7KGy / h to obtain the irradiated graphite.

[0046] (5) 180ml of concentrated sulfuric acid and 20ml of concentrated phosphoric acid will be taken, and the two acids will be stirred and mixed evenly. The mixed acid solution was transferred to a beaker of suitable size and placed in a water bath, heated at a constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com