Glass panel frosting process

A glass panel and process technology, applied in coating and other directions, can solve the problems that affect product quality and appearance, affect the comfort of mobile phone use, and the surface is higher than the frosted surface, so as to improve product quality and appearance, and avoid scratches. Defects, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

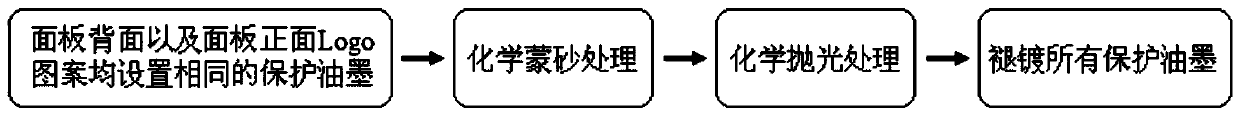

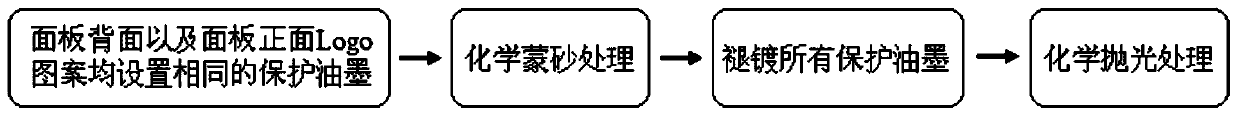

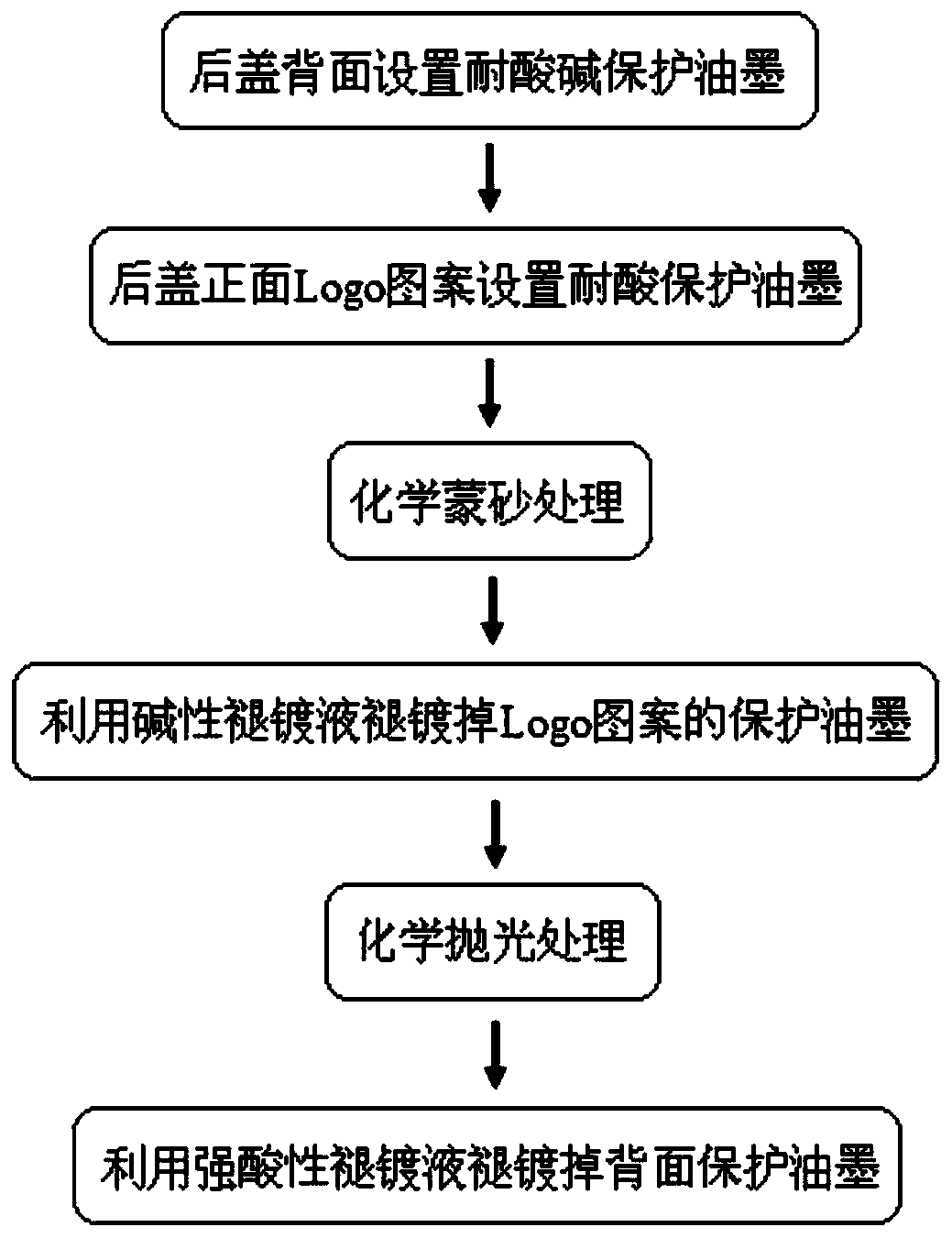

[0036] see image 3 , a glass panel frosting process, the panel is the back cover glass of the mobile phone and the previous CNC processing and other processes have been completed, the back side of the back cover is all designed as a non-frosted area, and the front side of the back cover is designed as Except for the Logo pattern which is a non-frosted area, the rest are frosted areas. The concrete process of described frosting process is as follows:

[0037] 1) Back protection: use silk screen or yellow light process to coat the back of the back cover with an acid and alkali resistant protective ink layer;

[0038] 2) Logo pattern protection: use silk screen or yellow light process to coat the logo pattern on the front of the back cover with an acid-resistant protective ink layer;

[0039] 3) Pre-cleaning treatment: the cleaning liquid is evenly sprayed on the front of the back cover through the nozzle, and the cleaning liquid includes 2% hydrofluoric acid, 10% sulfuric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com