Multi-phase common rail impulsing continuously variable transmission

A technology of continuously variable transmission and pulsating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

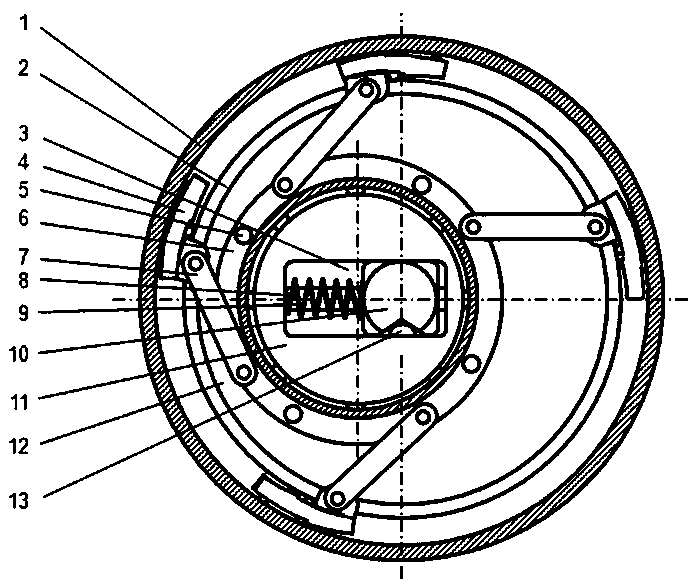

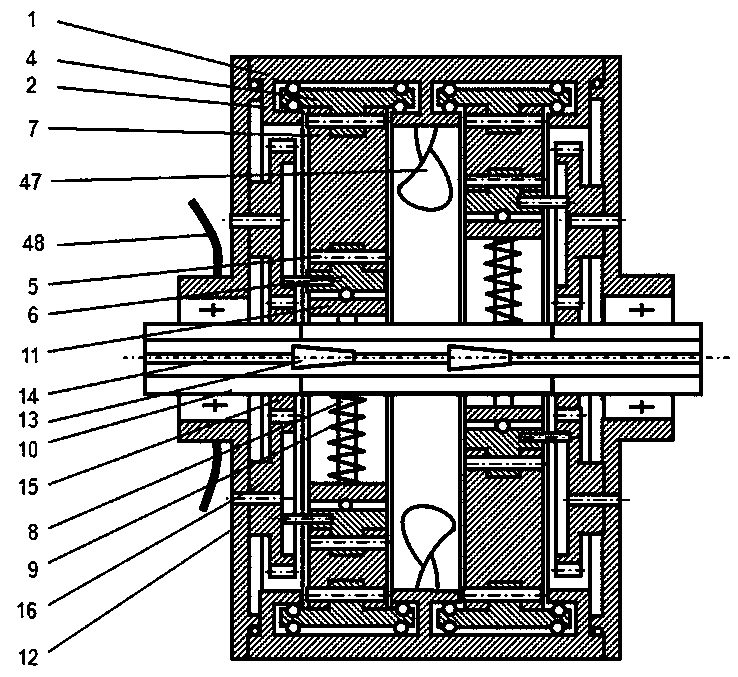

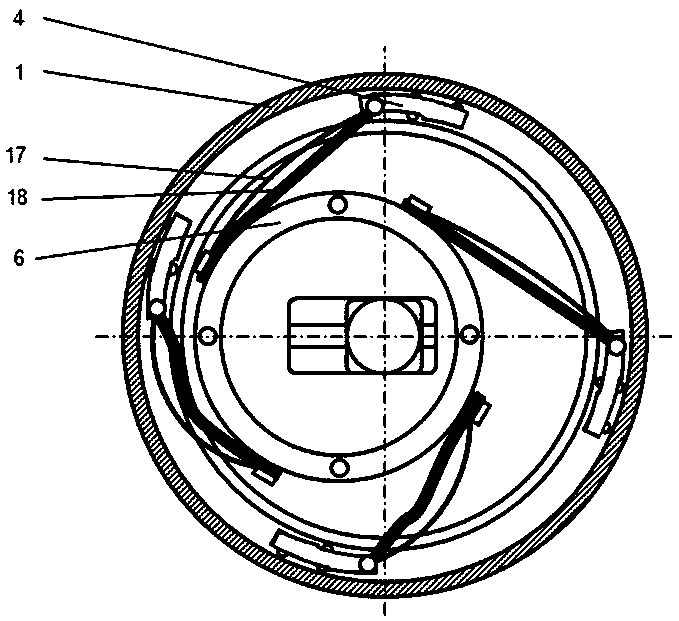

[0026] refer to figure 1 with figure 2 (If there is no additional specific reference to the legend in this paragraph in the same sentence, all refer to figure 1 with figure 2 ), the present invention includes a pulsating mechanism, an overrunning clutch mechanism, a transmission mechanism and a speed regulating mechanism. There is an eccentric wheel 11 in the pulsating mechanism, which is slidably connected with the power input shaft 10 for driving it through the radial chute 3 provided in its center But can not be in relative rotation, there is back-moving spring 9 between chute 3 and eccentric wheel 11, slide bar 8 is set in chute 3 and is slidably connected with input shaft 10, restricts the axial movement of eccentric wheel 11 and back-moving spring 9. When the eccentric wheel 11 rotates under the drive of the input shaft 10, its center revolves around the input shaft 10, and the centrifugal force is opposite to the force direction of the return spring 9, so that its e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com