Preparation method of high-performance memristor

A memristor, high-performance technology, applied in the field of non-volatile memory storage devices, can solve the constraints of memristor storage capacity, low-resistance, high-resistance state contrast memristor response speed, three-dimensional image surface roughness, Problems such as poor pattern uniformity, to achieve the effect of good pattern uniformity, small roughness, and obvious on and off states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

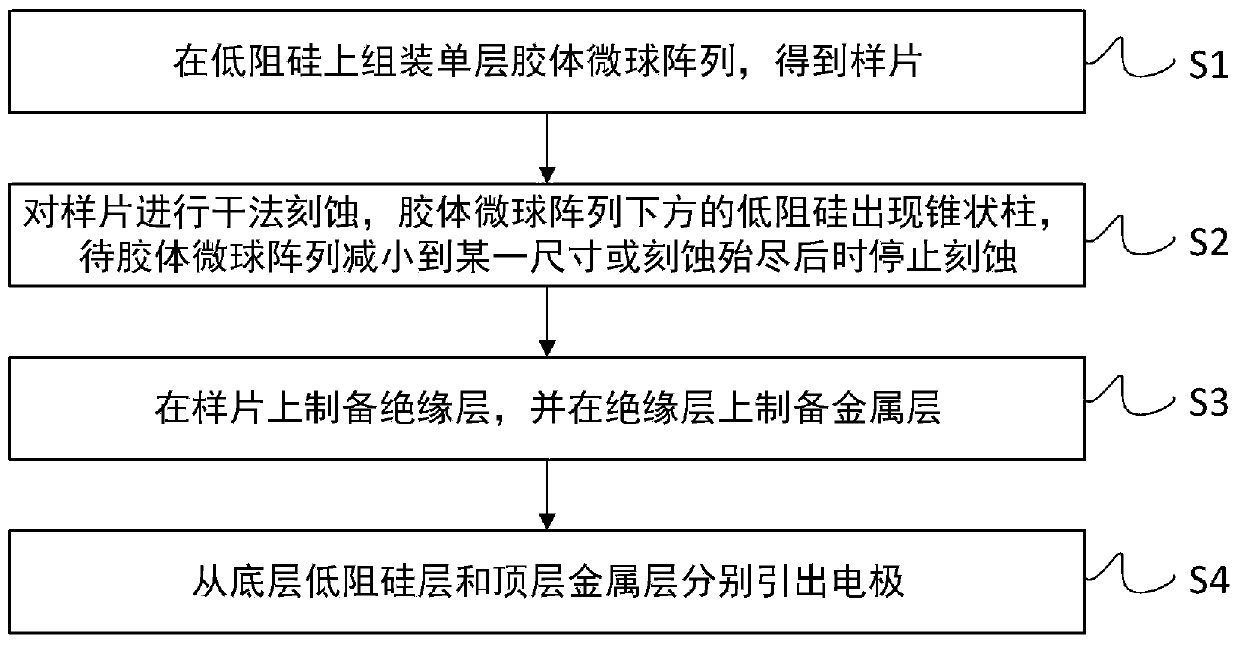

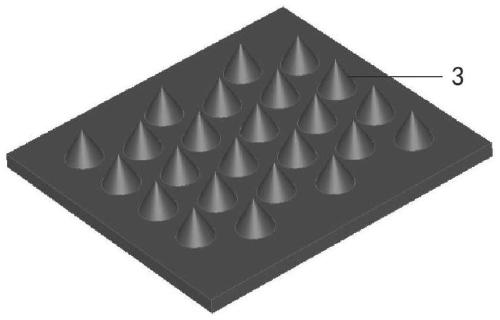

[0042] see figure 1 , figure 1 It shows a method for preparing a high-performance memristor disclosed in one of the exemplary embodiments of the present application, including the following steps:

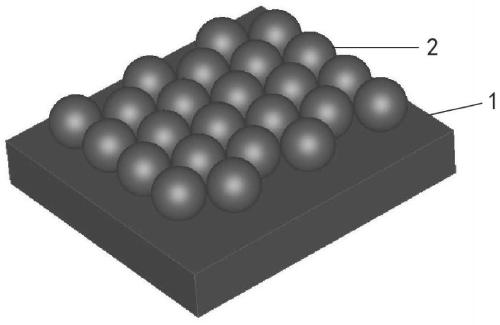

[0043] S1: if figure 2 As shown, a single-layer colloidal microsphere array 2 was assembled on low-resistance silicon 1 to obtain a sample.

[0044] Wherein, the low-resistance silicon is clean, dry and polished low-resistance silicon.

[0045]More preferably, in an exemplary embodiment, when the crystal orientation of the low-resistance silicon is 100, 110 or 111, the electrical conductivity is close to or lower than 0.01Ω·cm.

[0046] In yet another exemplary embodiment, the composition of the colloidal microspheres includes materials such as polymers, dielectrics, semiconductors, and metals, and the size of the colloidal microspheres is 30 nm˜100 μm.

[0047] In yet another exemplary embodiment, the method of assembling a single-layer colloidal microsphere array on low-resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com