Module combined type rope protector

A combination and protector technology, applied in life-saving equipment, building rescue, etc., can solve the problems of low dragging efficiency, large sliding friction coefficient of contact surface, insufficient strength, etc., to reduce rope resistance, protect ropes, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

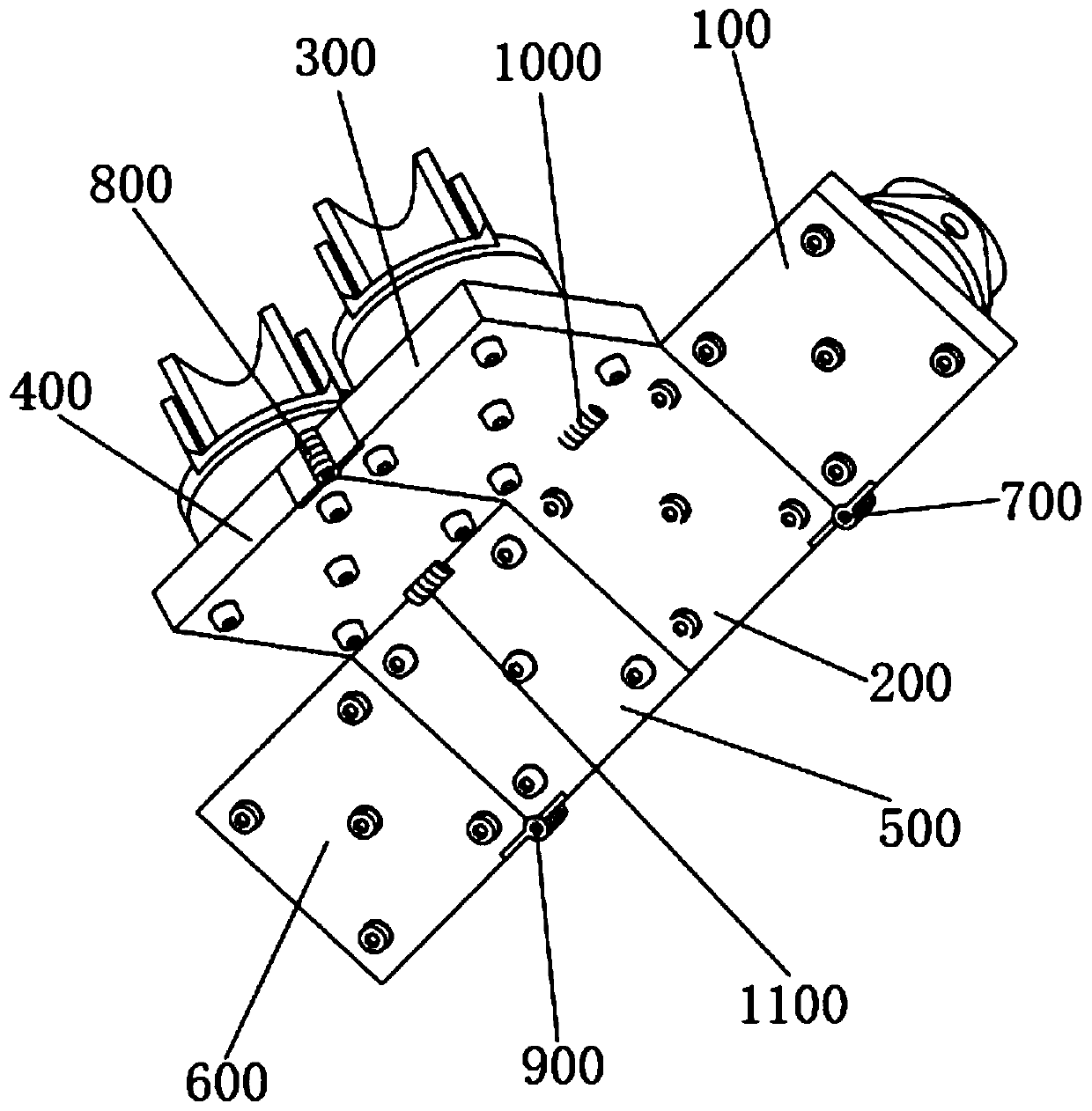

[0024] Please refer to figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a modular combined rope protector, including the first module 100, the second module 200, the third module 300, the fourth module 400, the fifth module 500 and the sixth module which are movably connected in sequence 600.

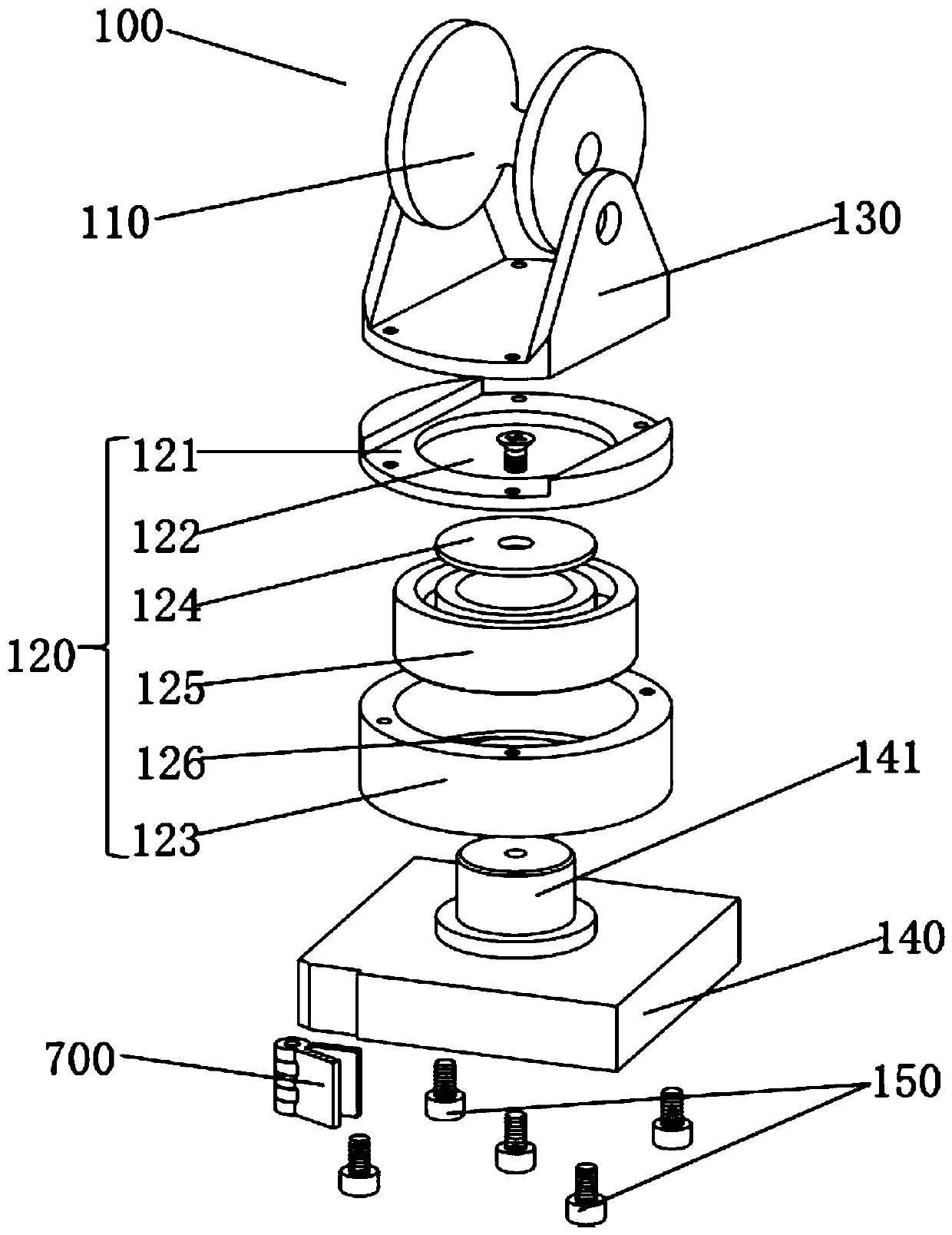

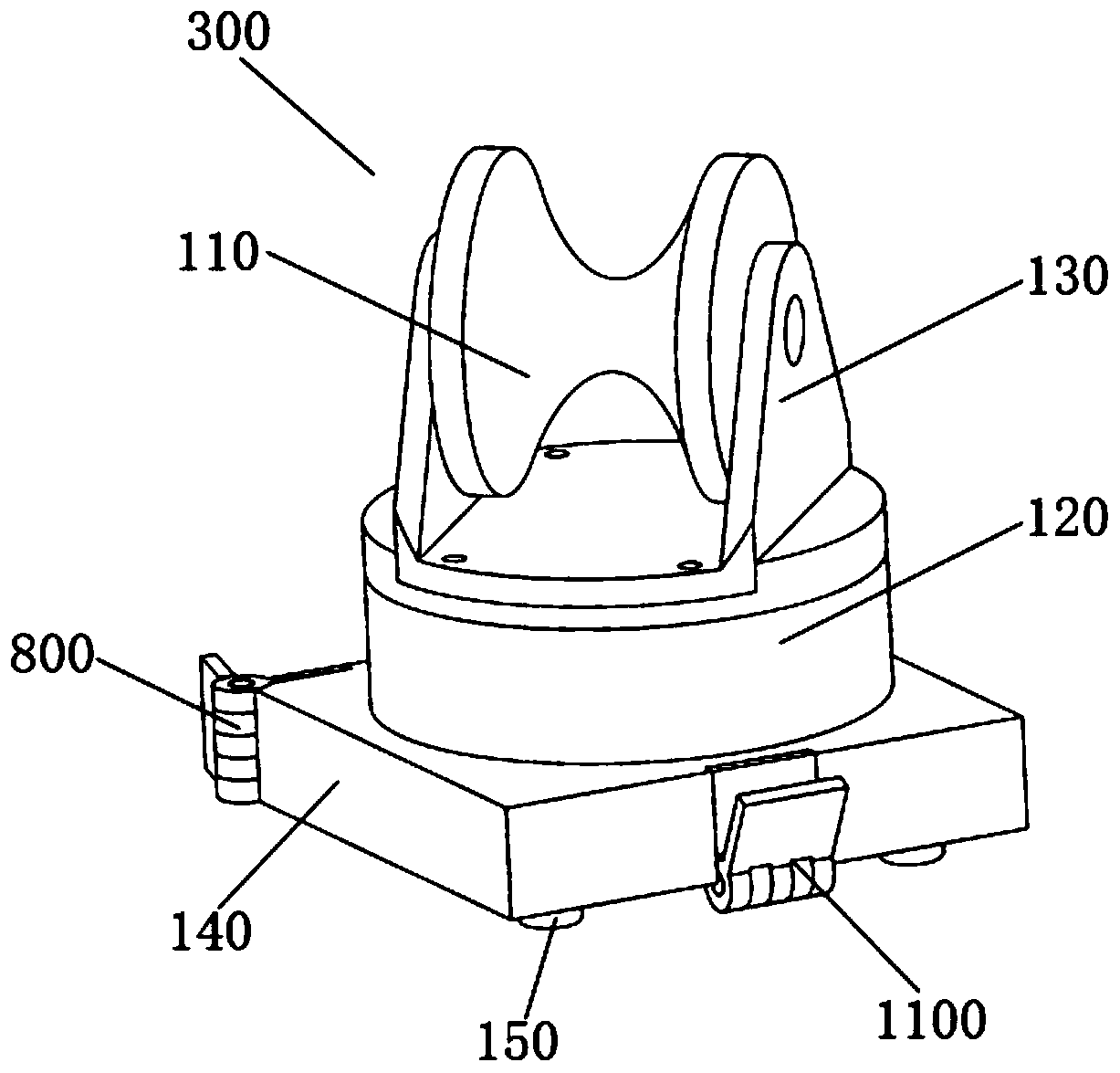

[0025] The first module 100 includes a U-shaped groove pulley 110, a rotating platform 120 and a base 140. The U-shaped groove pulley 110 is fixed on the rotating platform 120 through a bearing bracket 130. In this embodiment, the U-shaped groove The diameter of the edge of the outer ring of the pulley 110 becomes larger and protrudes to form a U-shaped groove. Preferably, the groove depth of the U-shaped groove pulley 110 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap