Resistance soldering tweezer self-adaptive system and self-adaptive adjusting method

An adaptive system and self-adaptive adjustment technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that resistance welding tongs cannot be adaptively adjusted, etc., and achieve the effect of strong self-regulation ability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments: the self-adaptive adjustment described in the present invention refers to that when the welding tongs itself changes, the welding tongs adjusts welding parameters according to their own state changes, the position of the welding tongs itself, etc. , automatically adapt to its own changes.

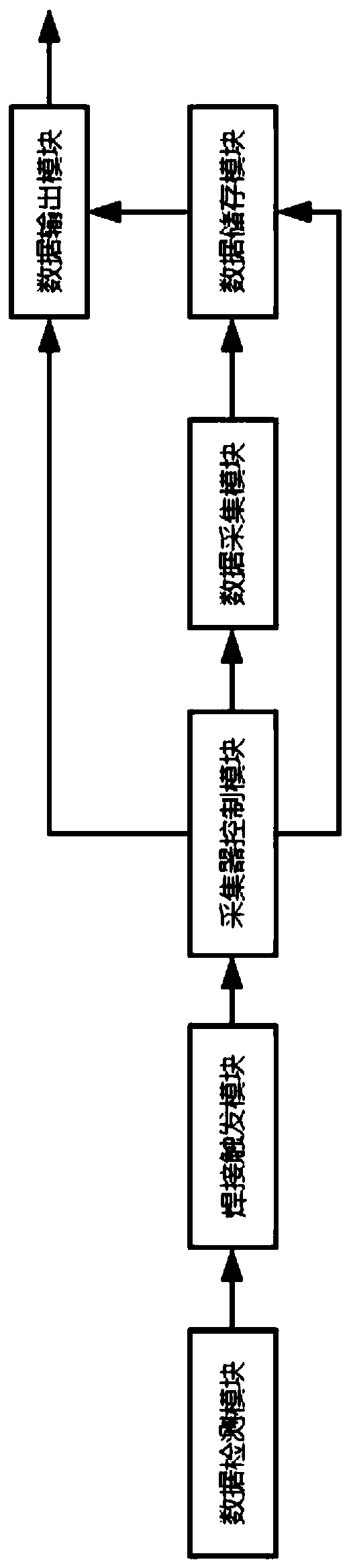

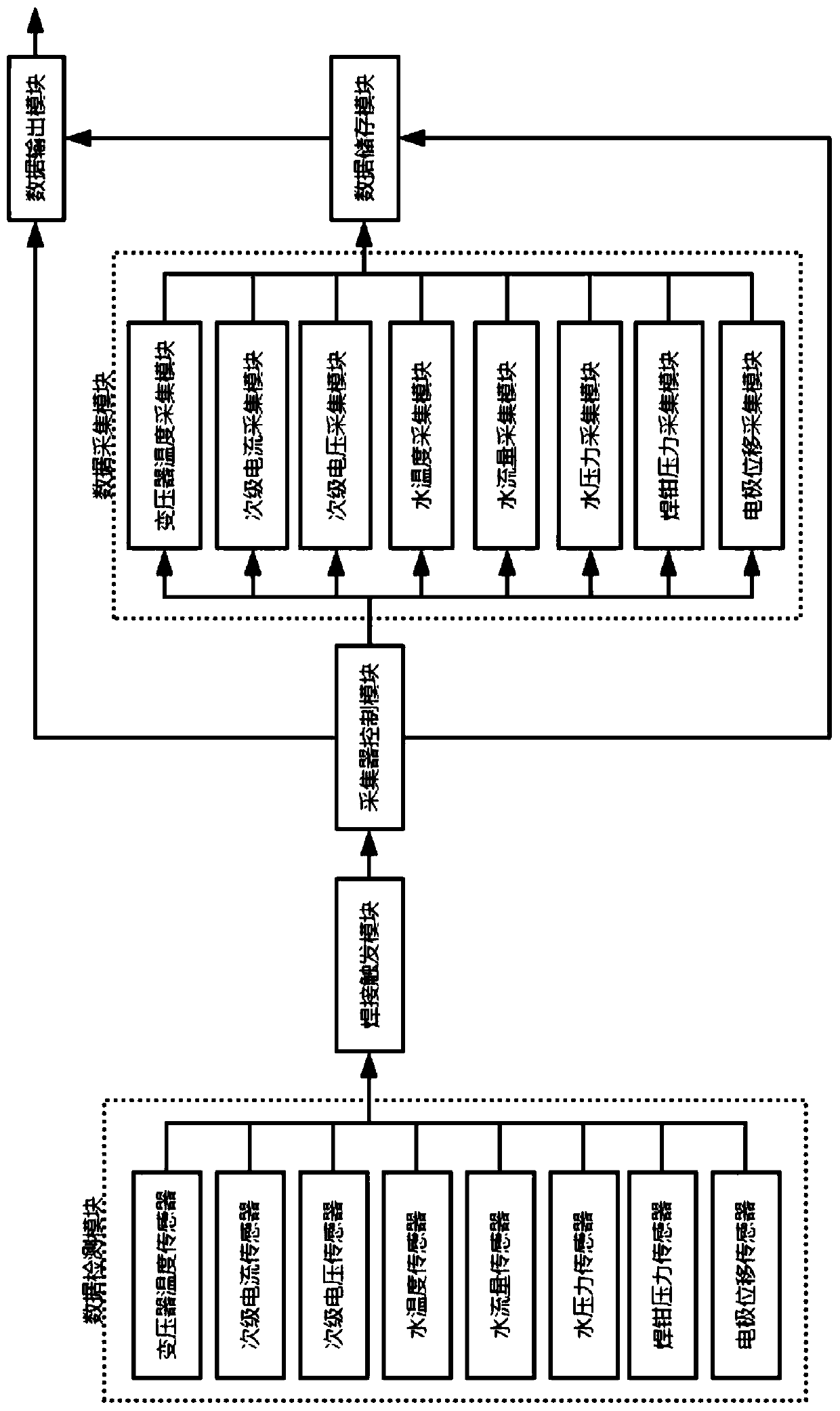

[0026] Such as Figure 1 to Figure 2 As shown, the resistance welding tongs adaptive system adopting the structure of the present invention includes a welding tongs body, a welding tongs boom, a welding tongs stationary arm, a transformer, and an electric cylinder for driving the boom to move. Especially suitable for C-type welding guns and X-type welding guns. The welding tongs body includes two side plates, the welding tongs moving arm and welding tongs stationary arm are all set on one side plate of the welding tongs body, the transformer and the electric cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com