Algae phase water system shrimp and shellfish conjoined circulating aquaculture system

A technology for recirculating aquaculture and shellfish farming, applied in fish farming, application, animal husbandry, etc., can solve the problems of energy consumption, equipment and manual maintenance and control, obvious fluctuations in purification treatment efficiency, and system effectiveness limitations, etc., to achieve The effects of increasing production and income, saving labor costs, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

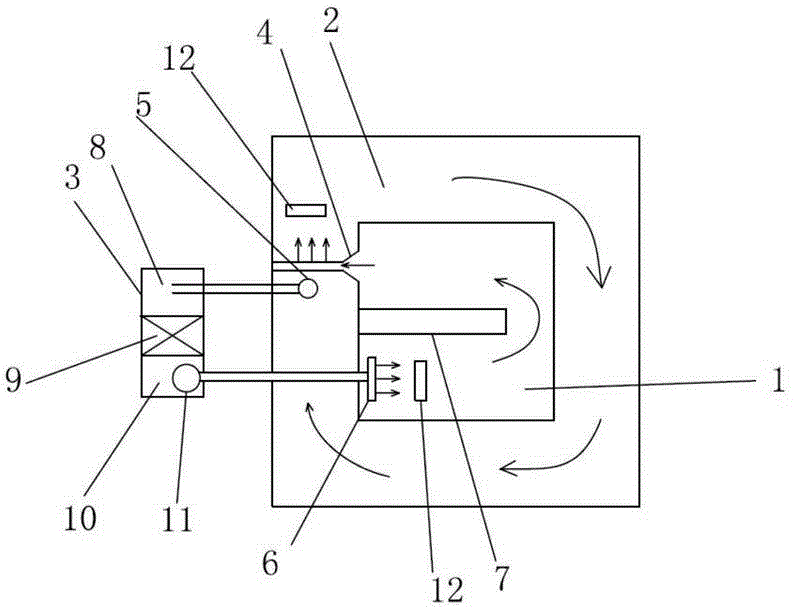

[0033] A kind of algae phase water system shrimp and shell conjoined recirculating aquaculture system, such as figure 1 As shown, it includes: a shellfish culture pond 1 located in the center, a ring-shaped shrimp culture pond 2 surrounding the shellfish culture pond 1 and an external water treatment device 3, the shellfish culture pond 1 is circular or square, and the shrimp culture pond 2 is circular or box-shaped. The culture area of shrimp culture pond 2 is 1000m 2 , and the area ratio of shellfish culture pond 1 and shrimp culture pond 2 is 3:5. The water depth of the prawn culture pond 2 is 1.8m, the water depth of the shellfish culture pond 1 is 2m, and the water level of the shellfish culture pond 1 is higher than that of the prawn culture pond 2, and the water level difference is 30cm.

[0034]The shellfish culture pond 1 is provided with the overflow type water outlet 4 leading to the prawn culture pond 2, and the prawn culture pond 2 is provided with a drain out...

Embodiment 2

[0038] A kind of algae phase water system shrimp and shell conjoined recirculating aquaculture system, such as figure 1 As shown, it includes: a shellfish culture pond 1 located in the center, a ring-shaped shrimp culture pond 2 surrounding the shellfish culture pond 1 and an external water treatment device 3, the shellfish culture pond 1 is circular or square, and the shrimp culture pond 2 is circular or box-shaped. The culture area of shrimp culture pond 2 is 1500m 2 , and the area ratio of shellfish culture pond 1 and shrimp culture pond 2 is 2:5. The water depth of the prawn culture pond 2 is 2.5m, the water depth of the shellfish culture pond 1 is 1.8m, the water level of the shellfish culture pond 1 is higher than the water level of the prawn culture pond 2, and the water level difference is 50cm.

[0039] The shellfish culture pond 1 is provided with the overflow type water outlet 4 leading to the prawn culture pond 2, and the prawn culture pond 2 is provided with a...

Embodiment 3

[0043] A kind of algae phase water system shrimp and shell conjoined recirculating aquaculture system, such as figure 1 As shown, it includes: a shellfish culture pond 1 located in the center, a ring-shaped shrimp culture pond 2 surrounding the shellfish culture pond 1 and an external water treatment device 3, the shellfish culture pond 1 is circular or square, and the shrimp culture pond 2 is circular or box-shaped. The culture area of shrimp culture pond 2 is 2000m 2 , and the area ratio of shellfish culture pond 1 and shrimp culture pond 2 is 2:5. The water depth of the prawn culture pond 2 is 2m, the water depth of the shellfish culture pond 1 is 2.5m, the water level of the shellfish culture pond 1 is higher than the water level of the prawn culture pond 2, and the water level difference is 60cm.

[0044] The shellfish culture pond 1 is provided with the overflow type water outlet 4 leading to the prawn culture pond 2, and the prawn culture pond 2 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com