Control system and method for adjusting filler in helmet

A technology for adjusting helmets and control systems, which is applied to helmets, helmet caps, cap products, etc., can solve the problems of scalp pain at the hair binding, inability to adjust fillers, and inability to fit the head, and achieves low cost, self- The effect of strong adjustment ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

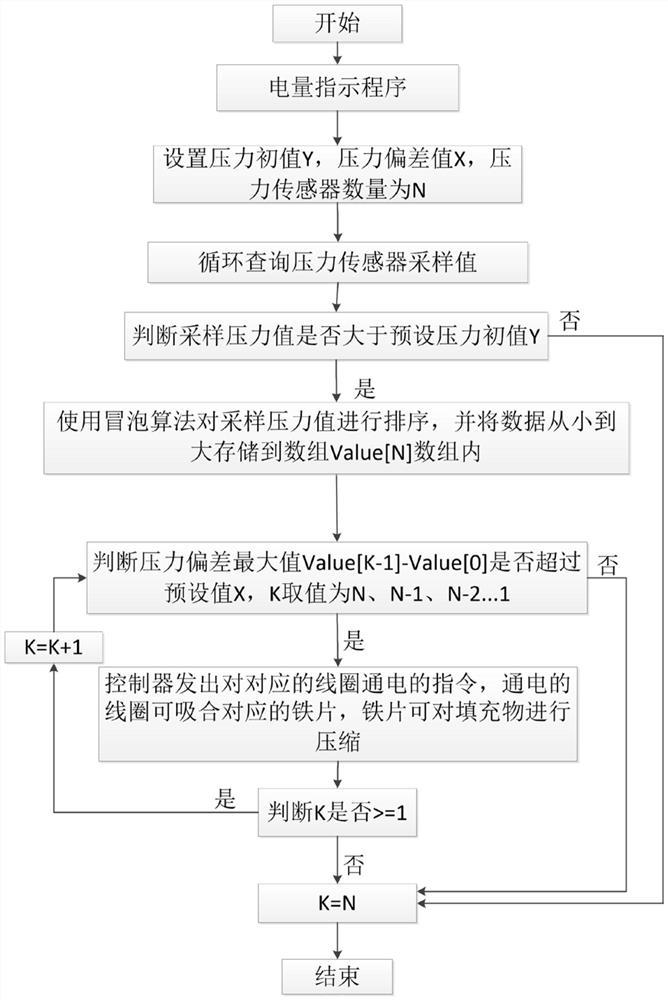

[0056] Such as Figure 1-2 As shown, a control system for adjusting the filling inside the helmet, including a control unit module, a pressure acquisition module, a power supply module and an adjustment module;

[0057] There is an electrical connection between the control unit module and the pressure acquisition module, an electrical connection between the power supply module and the control unit module, and an electrical connection between the adjustment module and the control unit module; the control unit module is used for process control of the entire system ,data processing;

[0058] The pressure acquisition module includes several groups of pressure sensors, and the adjustment module includes several groups of tension driving devices. Each group of tension driving devices is connected with a group of pressure sensors. The pressure sensors detect pressure changes and transmit the signals of pressure changes to the control unit module. , the control unit module issues an...

Embodiment 2

[0088] Embodiment 2: do further design on the basis of embodiment 1:

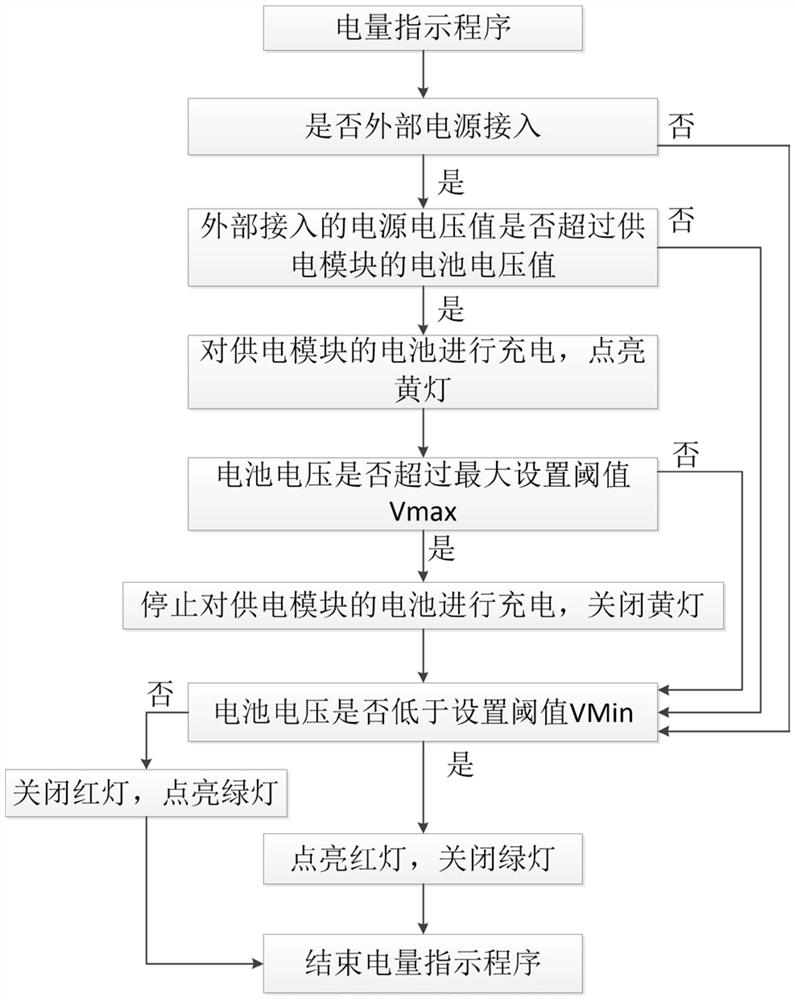

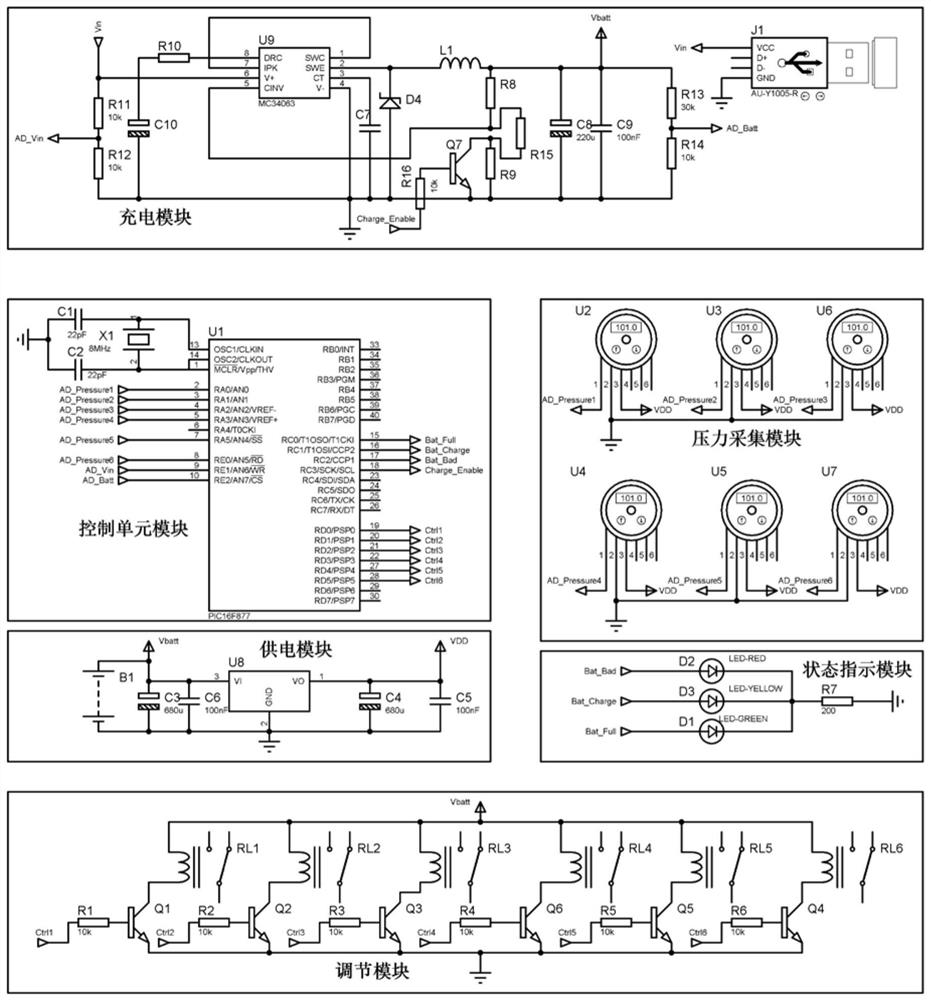

[0089] Such as image 3 Shown, a circuit that adjusts the padding inside the helmet

[0090] Including the first capacitor, the second capacitor, the third capacitor, the fourth capacitor, the fifth capacitor, the sixth capacitor, the seventh capacitor, the first resistor, the second resistor, and the third resistor , No. 4 resistor, No. 5 resistor, No. 6 resistor, No. 7 resistor, No. 8 resistor, No. 9 resistor, No. 10 resistor, No. 11 resistor, No. 12 resistor , No. 13 resistor, No. 14 resistor, No. 15 resistor, No. 16 resistor, single chip microcomputer, No. 1 pressure sensor, No. 2 pressure sensor, No. 3 pressure sensor, No. 1 pressure sensor No. 4 pressure sensor, No. 5 pressure sensor, No. 6 pressure sensor, voltage regulator chip, charging chip, No. 1 triode, No. 2 triode, No. 3 triode, No. 4 triode, No. 5 triode, No. Transistor No. 6, Triode No. 7, Green Indicator, Red Indicator, Yellow Indicator,...

Embodiment 3

[0092] Embodiment 3: do further design on the basis of embodiment 1

[0093] Such as Figure 4-5 As shown, a helmet with an adjustable internal filling includes a helmet shell 1, a filling 2, a circuit board 4, several sets of adjustment modules 3 and several sets of pressure acquisition modules 5; the filling 2 is fixedly connected to the helmet shell 1 on the inner side wall of the inner side wall; the adjustment module 3 includes a coil 31 and an iron sheet 32, the coil 31 is embedded between the helmet shell 1 and the filler 2, the iron sheet 32 is fixedly connected on the inner side wall of the filler 2, and the iron sheet 32 is covered with The inner side wall of the filler 2, the position of the coil 31 corresponds to the position of the iron sheet 32; the circuit board 4 is placed inside the helmet shell 1, and the pressure acquisition module 5 is fixedly connected on the lower surface of the iron sheet 32; the adjustment module 3 The quantity is consistent with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com