Spray pump rim thruster

A propeller and rim technology, which is applied in the field of energy conversion construction machinery, can solve the problems of speed increase and achieve the effects of increased power, low friction coefficient and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

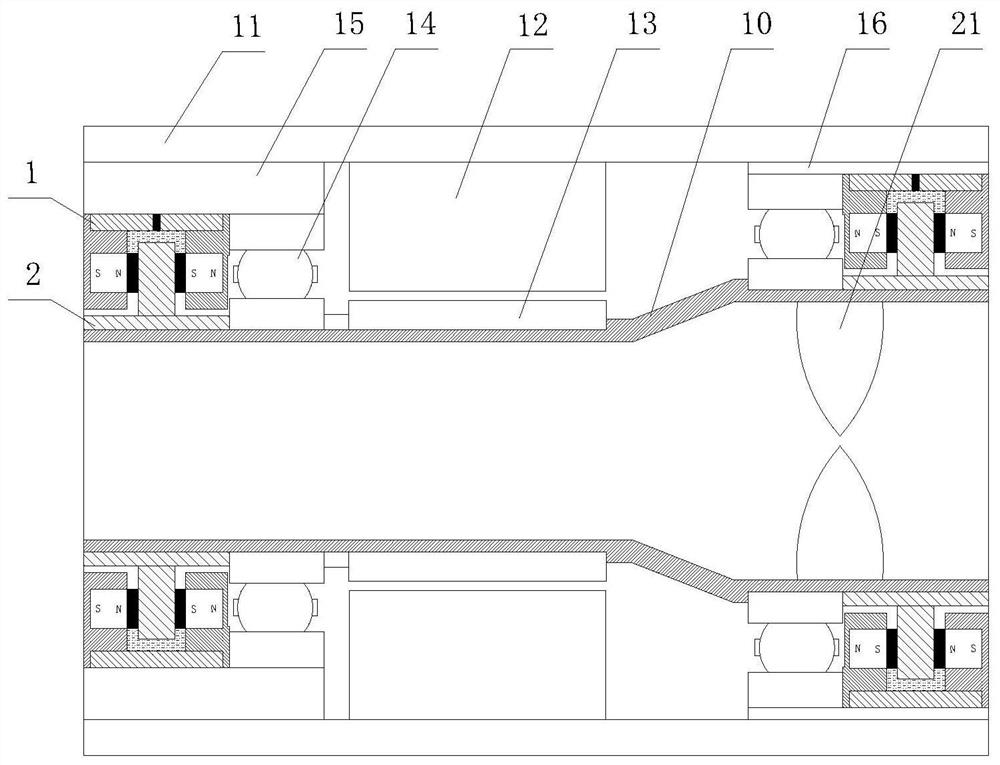

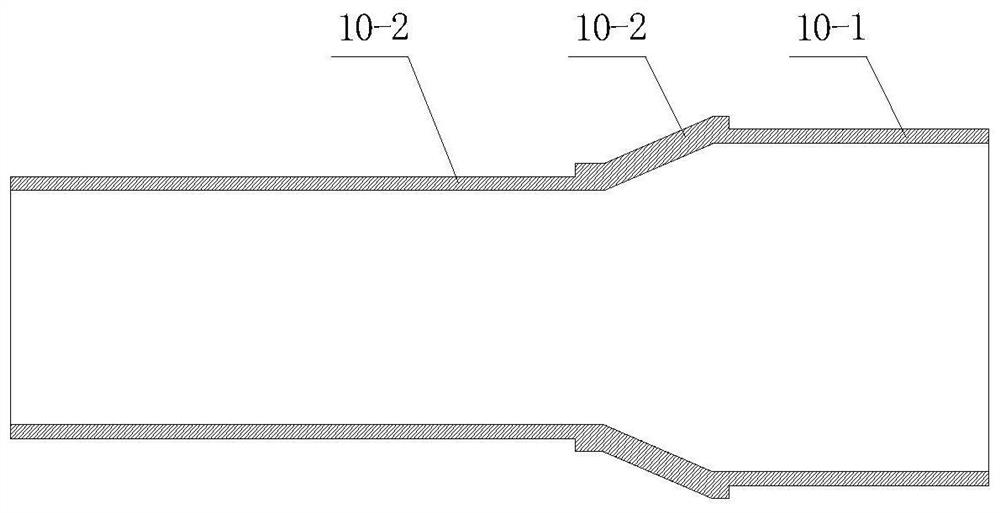

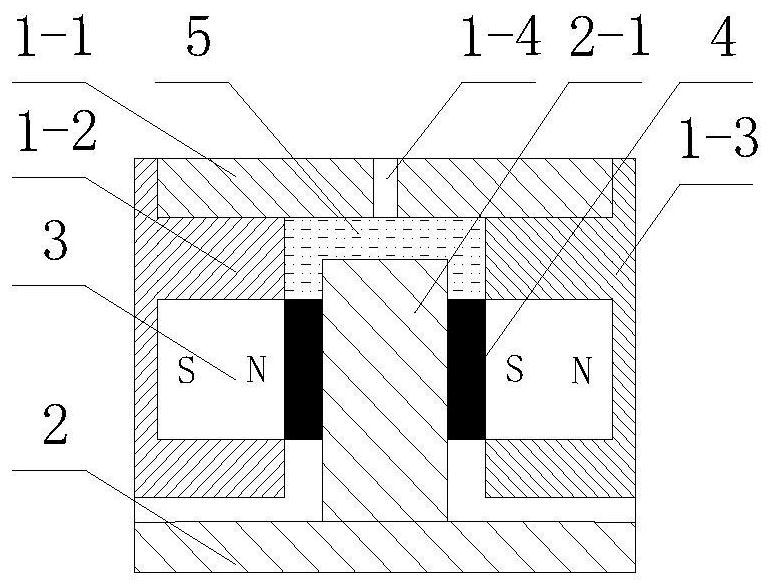

[0037] like Figure 1~4 As shown, a jet pump rim propeller includes a rotating shaft 10, a casing 11, a stator 12, and a rotor 13. The rotating shaft 10 is hollow and has a trumpet-like structure, and is movably connected to a shaft fixed to the casing 11 through a bearing 14. In the front end cover 15 and the rear end cover 16 on both sides, the rotating shaft 10 includes a large end portion 10-1, a small end portion 10-3 and a gradual change portion 10-2 connecting the large end portion and the small end portion; The inner side of the big end 10-1 is used for fixing the blade 21, and the small end 10-3 is used for fixing the rotor 13; the stator 12 is fixedly installed in the casing 11, corresponding to the rotor 13; The outer side of the bearing 14 is provided with a sealing assembly; the sealing assembly includes an outer ring 1 and an inner ring 2, which are respectively fixed on the end cover and the rotating shaft. ” type groove, which is composed of jacket 1-1, left c...

Embodiment 2

[0040] like Figure 5-6 As shown, a jet pump rim propeller includes a rotating shaft 10, a casing 11, a stator 12, and a rotor 13. The rotating shaft 10 is hollow and has a trumpet-like structure, and is movably connected to a shaft fixed to the casing 11 through a bearing 14. In the front end cover 15 and the rear end cover 16 on both sides, the rotating shaft 10 includes a large end portion 10-1, a small end portion 10-3 and a gradual change portion 10-2 connecting the large end portion and the small end portion; The inner side of the big end 10-1 is used for fixing the blade 21, and the small end 10-3 is used for fixing the rotor 13; the stator 12 is fixedly installed in the casing 11, corresponding to the rotor 13; The outer side of the bearing 14 is provided with a sealing assembly; the sealing assembly includes an outer ring 1 and an inner ring 2, which are respectively fixed on the end cover and the rotating shaft. ” type groove, which is composed of jacket 1-1, left c...

Embodiment 3

[0043] like Figure 7-8 As shown, a jet pump rim propeller includes a rotating shaft 10, a casing 11, a stator 12, and a rotor 13. The rotating shaft 10 is hollow and has a trumpet-like structure, and is movably connected to a shaft fixed to the casing 11 through a bearing 14. In the front end cover 15 and the rear end cover 16 on both sides, the rotating shaft 10 includes a large end portion 10-1, a small end portion 10-3 and a gradual change portion 10-2 connecting the large end portion and the small end portion; The inner side of the big end 10-1 is used for fixing the blade 21, and the small end 10-3 is used for fixing the rotor 13; the stator 12 is fixedly installed in the casing 11, corresponding to the rotor 13; The rotating shaft 10 has a hollow structure, with paddles 21 fixed on the inside; sealing assemblies are provided on both sides of the bearing 14; the sealing assembly includes an outer ring 1 and an inner ring 2, which are respectively fixed on the end cover a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com