Bonding welding system and bonding welding method

A technology of welding system and welding method, which is applied in the field of hot-press welding, can solve the problems of long operation time for the staff to place the PCB board, affect the welding accuracy, and affect the processing efficiency, etc., so as to reduce the probability of glue flow, high work efficiency, and reduce the number of times The effect of product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

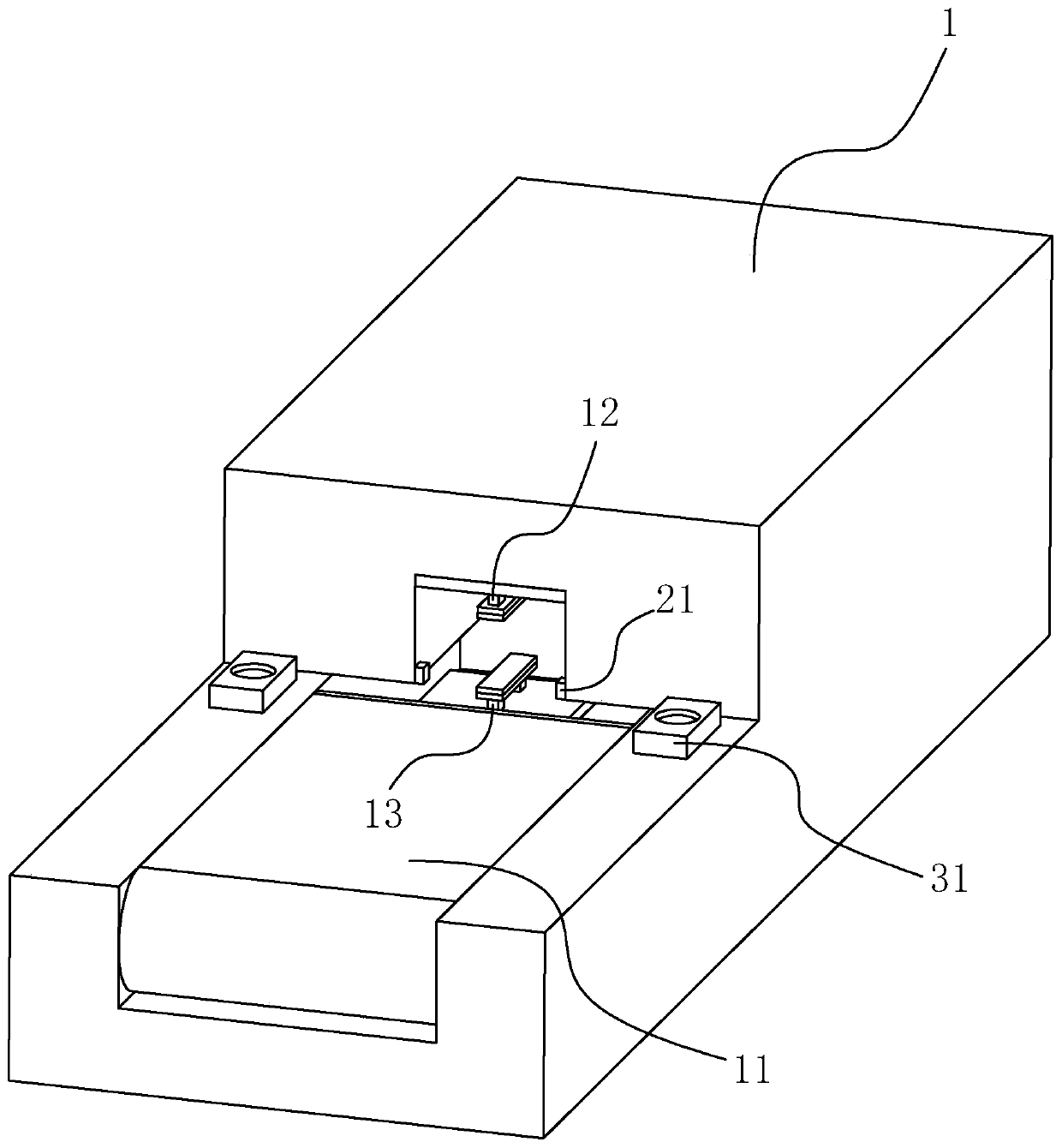

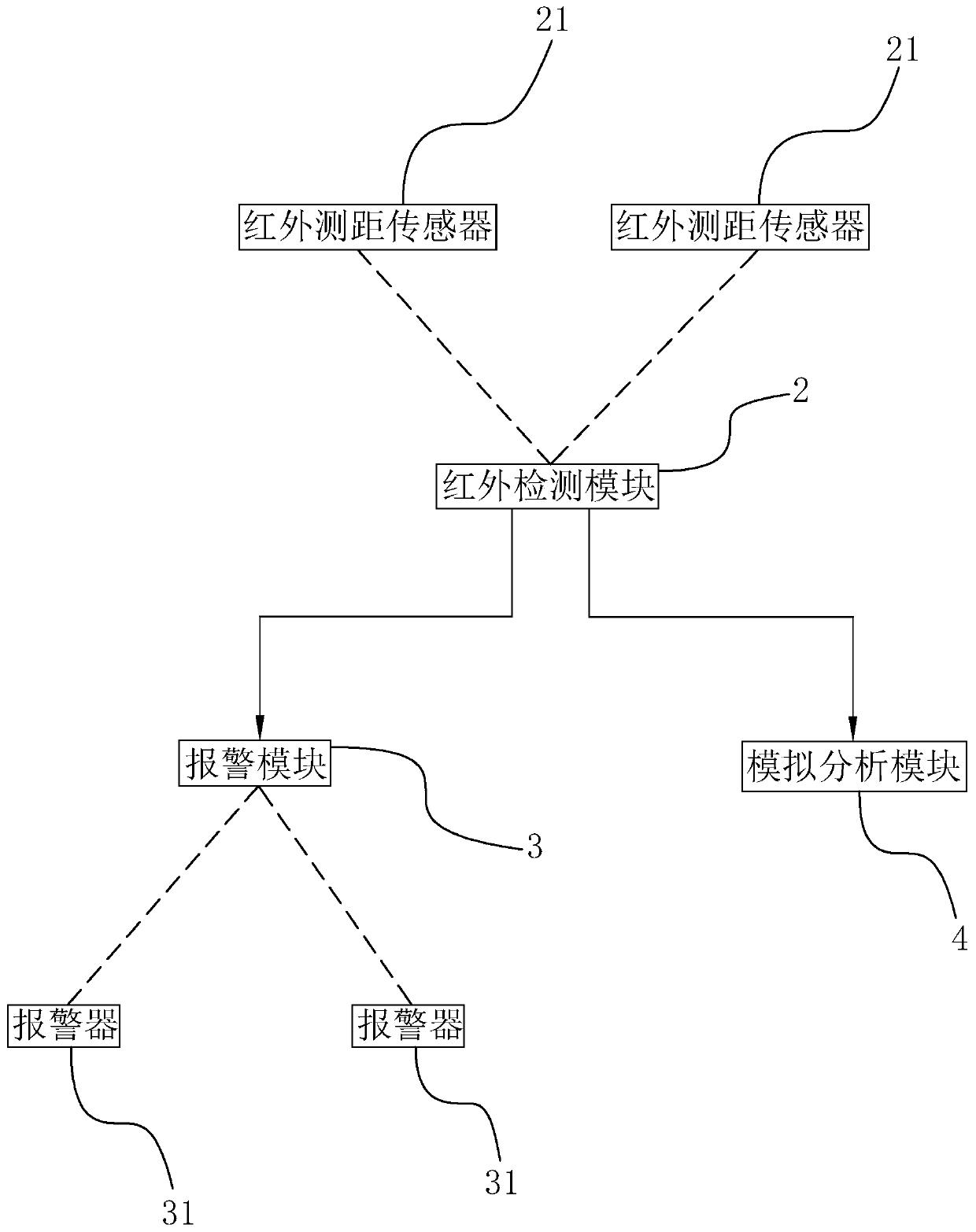

[0048] Embodiment one: a kind of bonding welding system, such as figure 1 As shown, a thermocompression welding device 1 is included, and a feeding conveyor belt 11 is connected to the feed port of the thermocompression welding device 1 . Two infrared range-finding sensors 21 are fixedly connected to the position of the thermocompression welding equipment 1 close to the feeding conveyor belt 11. It is arranged along the conveying direction of the feeding conveyor belt 11. The distance between the two infrared ranging sensors 21 is equal to the width of the workpiece.

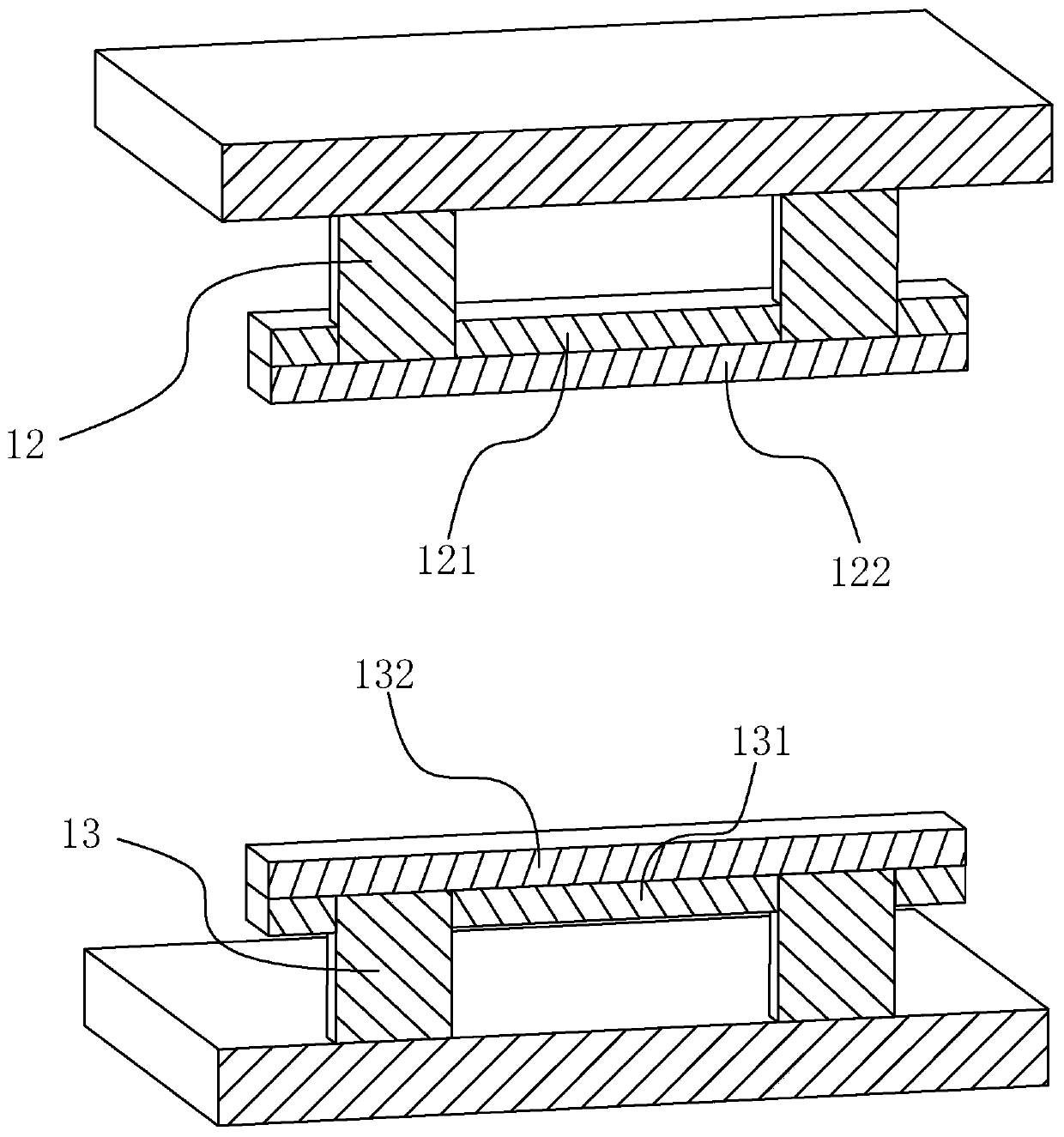

[0049] Such as figure 1 and figure 2As shown, the thermocompression welding equipment 1 includes an upper welding head 12 and a lower welding head 13 . An upper pressing plate 121 is fixedly connected to the upper welding head 12 , and a lower pressing plate 131 is fixedly connected to the lower welding head 13 . The upper platen 121 is fixedly connected with an upper high temperature resistant Teflon 122 ...

Embodiment 2

[0052] Embodiment two: a kind of bonding welding method, concrete steps are as follows:

[0053] Step 1. Install two infrared distance measuring sensors 21 near the feeding conveyor belt 11 in the thermocompression welding equipment 1, so that the infrared light emitted by the two infrared distance measuring sensors 21 is parallel and the distance is equal to the width of the workpiece.

[0054] Step 2, the staff places the workpiece on the feeding conveyor belt 11, and makes two infrared rays pass along both sides of the workpiece as much as possible.

[0055] Step 3: If the position of the workpiece is incorrect, the two alarms 31 on the thermocompression welding equipment 1 will send out an alarm according to which side the workpiece is deflected to. Workers adjust the position of the workpiece. If the position of the workpiece is correct, the staff starts the feeding conveyor belt 11 and the thermocompression welding equipment 1 to weld the workpiece. It can make it easi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com