A kind of easy tear film and its preparation method and application

A technology of easy tearing film and pressing roller, applied in application, other household appliances, chemical instruments and methods, etc., can solve the problems of complex process, influence on shelf life, difficult process control, etc., and achieve the effect of simple preparation method and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

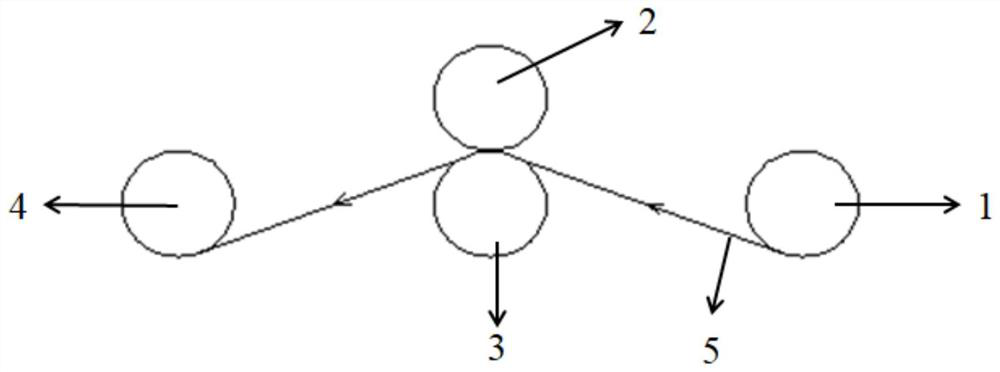

[0061] An easy-to-tear film, such as figure 1 As shown, the preparation method is as follows:

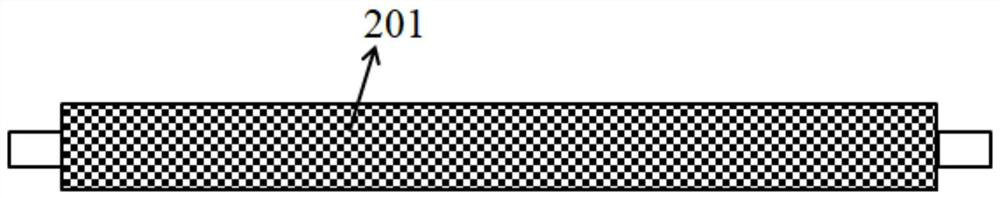

[0062] A set of easy-tear treatment devices are provided, wherein the easy-tear treatment devices include a first guide roller 1 and a second guide roller 4, and a metal 3 located between the first guide roller 1 and the second guide roller 4. A pressing roller 2 is arranged above, and a processing section 201 is arranged on the pressing roller 2, such as figure 2 As shown, the processing section is covered with the surface of the pressure roller 2; the easy-tear treatment device also includes and a color mark sensor.

[0063] The processing process of easy tear film is as follows:

[0064] After unwinding the film to be processed, it is guided to the second guide roller 4 through the first guide roller 1. During this period, the film to be processed is pressed against the side of the metal roller 3, and passes through the gap between the pressing roller 2 and the metal roller 3....

Embodiment 2

[0067] An easy-tear film is composed of a polyethylene terephthalate layer, a low-density polyethylene layer, an aluminum foil layer and a polyethylene layer which are arranged in sequence.

[0068] The preparation method is as follows:

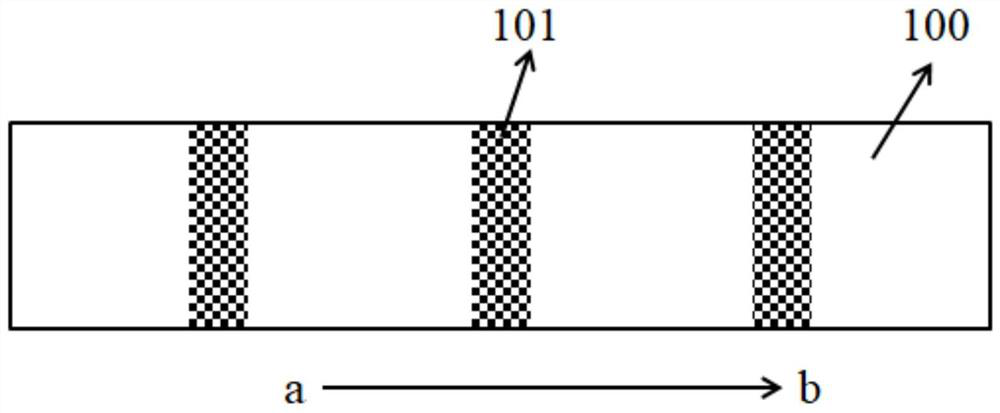

[0069] A set of easy-tear treatment devices are provided, wherein the easy-tear treatment devices include a first guide roller and a second guide roller, and a metal roller located between the first guide roller and the second guide roller, and a pressing roller is arranged above the metal roller, There are multiple processing sections on the pressure roller, such as Figure 4 As shown, the processing sections 201 are arranged at intervals along the circumferential direction of the pressing roller 2, and each processing section includes a plurality of groups of metal needles; the easy-tear processing device also includes and a color mark sensor.

[0070] The processing process of easy tear film is as follows:

[0071] After the polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com