High-temperature-resistant hot-melt pressure-sensitive adhesive and preparation method thereof

A warm, melt-pressing technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as insufficient pressure-sensitive adhesive retention and initial tack, and reduce Pollution, easy to tear off, average mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

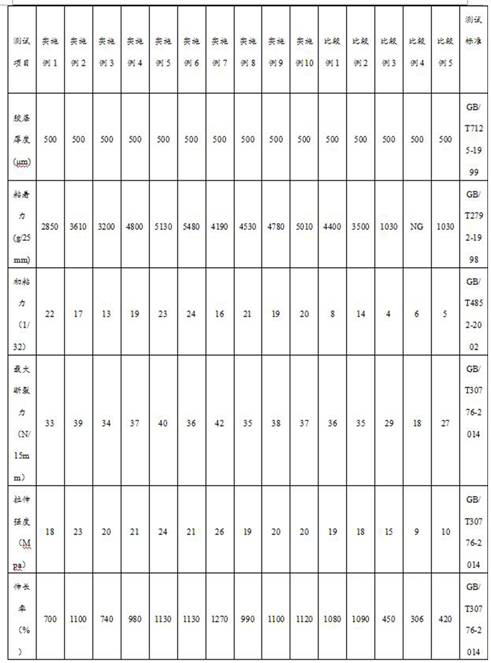

Embodiment 1

[0031] Embodiment 1 of the present invention: a high-temperature-resistant hot-melt pressure-sensitive adhesive, comprising the following components in parts by mass: 30 parts of SBS, 60 parts of rosin resin, 10 parts of industrial gelatin, 6 parts of dibutyl phthalate, 33 parts methyl methacrylate, 5 parts benzoyl peroxide, 2 parts antioxidant 264.

Embodiment 2

[0032] Embodiment 2: A kind of heat-resistant hot-melt pressure-sensitive adhesive, including the following components in parts by mass: 86 parts of SBS, 76 parts of terpene resin, 20 parts of industrial gelatin, 5 parts of dibutyl phthalate, 30 parts of Methyl Methacrylate, 5 parts Benzoyl Peroxide, 2 parts Antioxidant 264.

Embodiment 3

[0033] Embodiment 3: A kind of high-temperature-resistant hot-melt pressure-sensitive adhesive comprises the following components in parts by mass: 63 parts of SIS, 70 parts of terpene phenol resin, 20 parts of industrial gelatin, 6.5 parts of dibutyl phthalate, 40 parts Parts of isooctyl acrylate, 5 parts of benzoyl peroxide, 2 parts of antioxidant 264.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com