High-temperature-resistant packaging bag

A packaging bag, high temperature resistant technology, applied in the field of packaging bags, can solve the problems of uneven stress distribution, food splashing, affecting product performance, etc., achieve good tensile strength and elongation, improve aluminum foil breakage, good protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

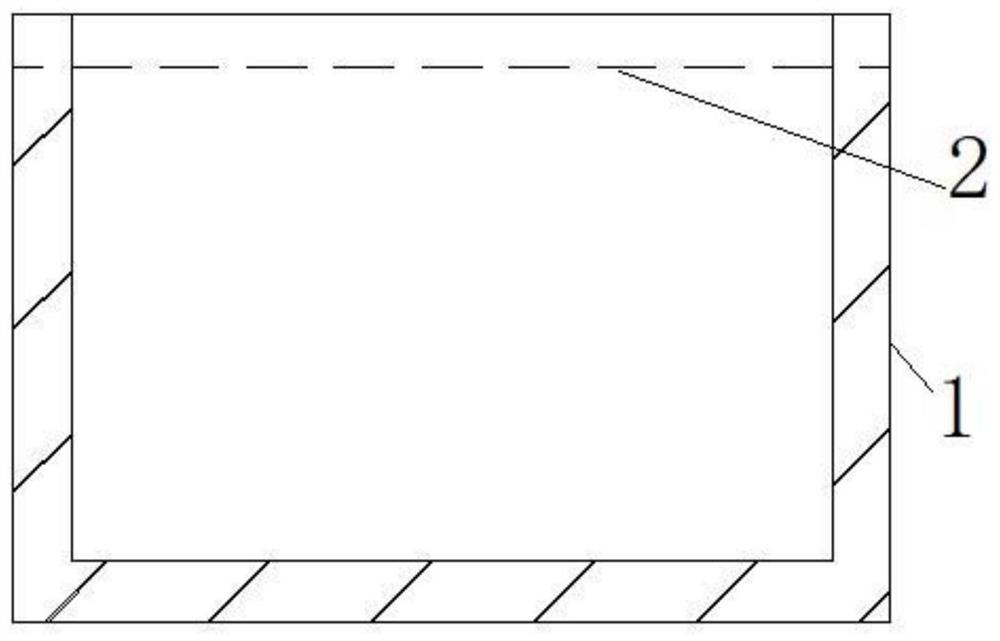

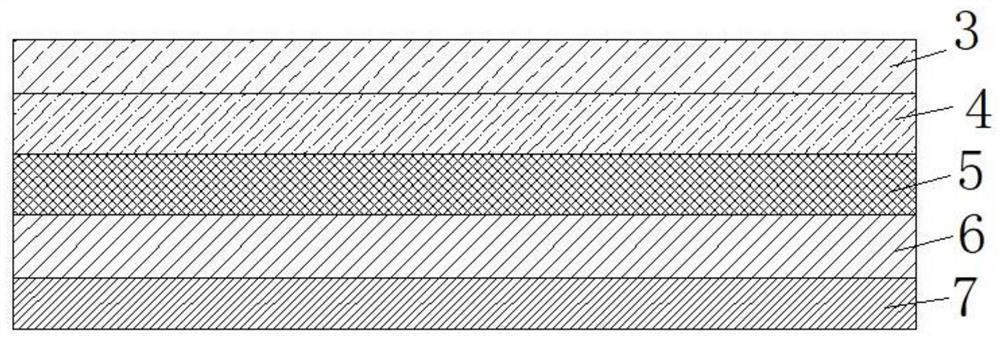

[0027] like Figure 1 to Figure 3 As shown, a high-temperature-resistant packaging bag includes a bag body 1 and a tear opening located on the edge of the bag body 1. The bag body 1 is sequentially bonded with an adhesive to set the first aluminum foil layer 3, the first A nylon layer 4, a polyethylene film layer 5, a polyester film layer 6 and a polypropylene film layer 7, and the bag body 1 is provided with a linear laser line 2 along the direction of the tear opening. Specifically, when making the bag body, the inner surface of the first aluminum foil layer 3 is bonded to the outer surface of the first nylon layer 4 through polyurethane, and the inner surface of the first nylon layer is bonded to the outer surface of the polyethylene film layer 5 through polyurethane. The inner surface of the polyethylene film layer 5 is bonded to the outer surface of the polyester film layer 6, and the inner surface of the polyester film layer 6 is bonded to the outer surface of the polypr...

Embodiment 2

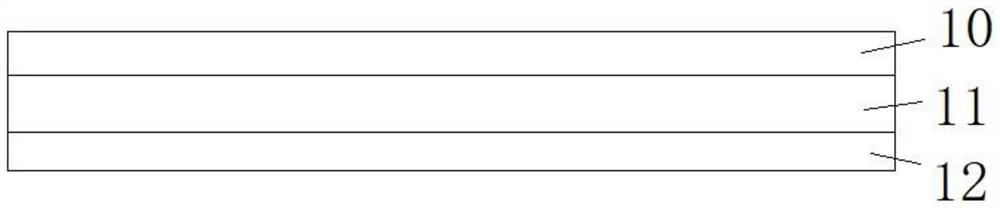

[0031] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the high-temperature-resistant packaging bag also includes a polyethylene terephthalate film 8 and a second nylon layer 9 bonded on the outside of the first aluminum foil layer 3 from outside to inside by an adhesive. Specifically, after bonding the film layers in the first aluminum foil layer, the outer surface of the first aluminum foil layer is bonded to the inner surface of the second nylon layer by polyurethane, and the outer surface of the second nylon layer is bonded by polyurethane Bonded to the inner surface of the polyethylene terephthalate film 8 . This kind of structural setting makes the packaging bag change from the original layer of nylon film and aluminum foil film to two layers of nylon film wrapped with aluminum foil film, so as to better protect the aluminum foil film and effectively improve the breakage of the aluminum foil when it is folded in half. Polyethylene...

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that bamboo charcoal particles are evenly distributed in the first aluminum foil layer 3 , calculated by mass percentage, the content of aluminum foil accounts for 94%, and the content of bamboo charcoal particles accounts for 6%. The thickness of the first aluminum foil layer is 4mm. Adopting this kind of structural arrangement makes the first aluminum foil layer as the outer layer have better antibacterial performance, and increases the external antibacterial effect when the packaging bag is stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com