An automatic assembly machine for tire inner tube parts

A technology for assembly machines and inner tubes, which is applied in tire installation, tire parts, vehicle parts, etc., can solve the problems not involved in the automatic assembly of tire inner tube parts, etc., to improve assembly production efficiency, high practical value and promotion value , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

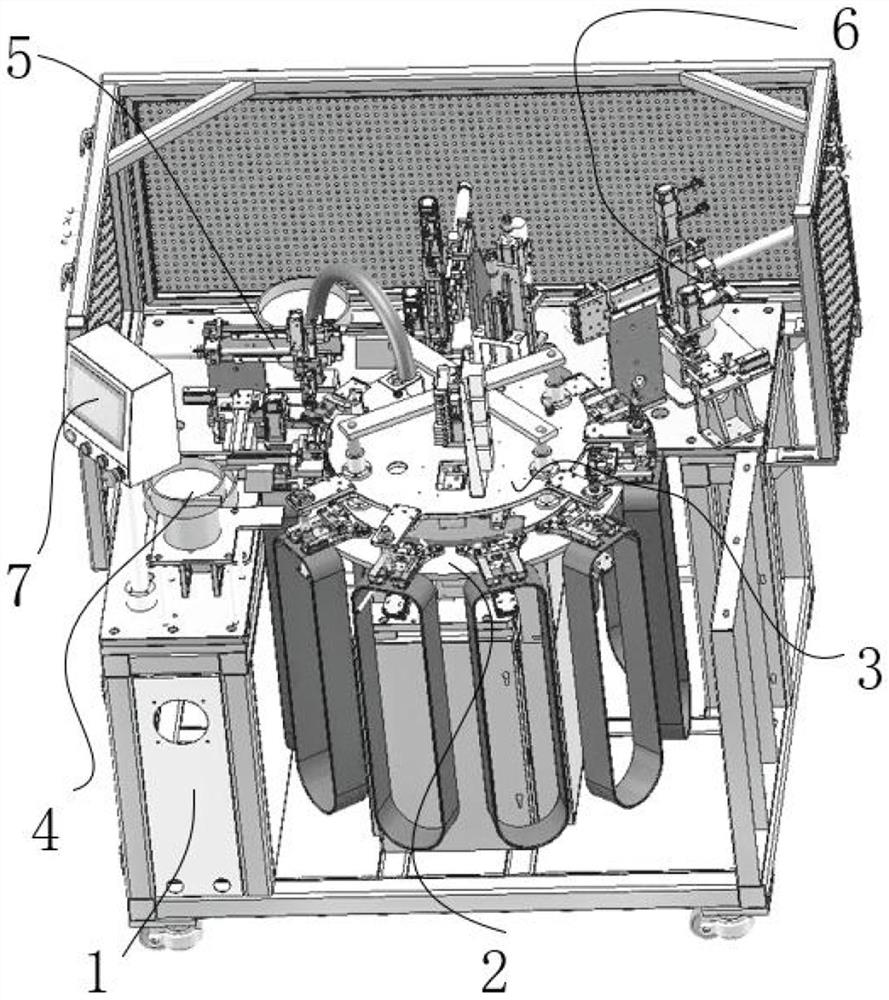

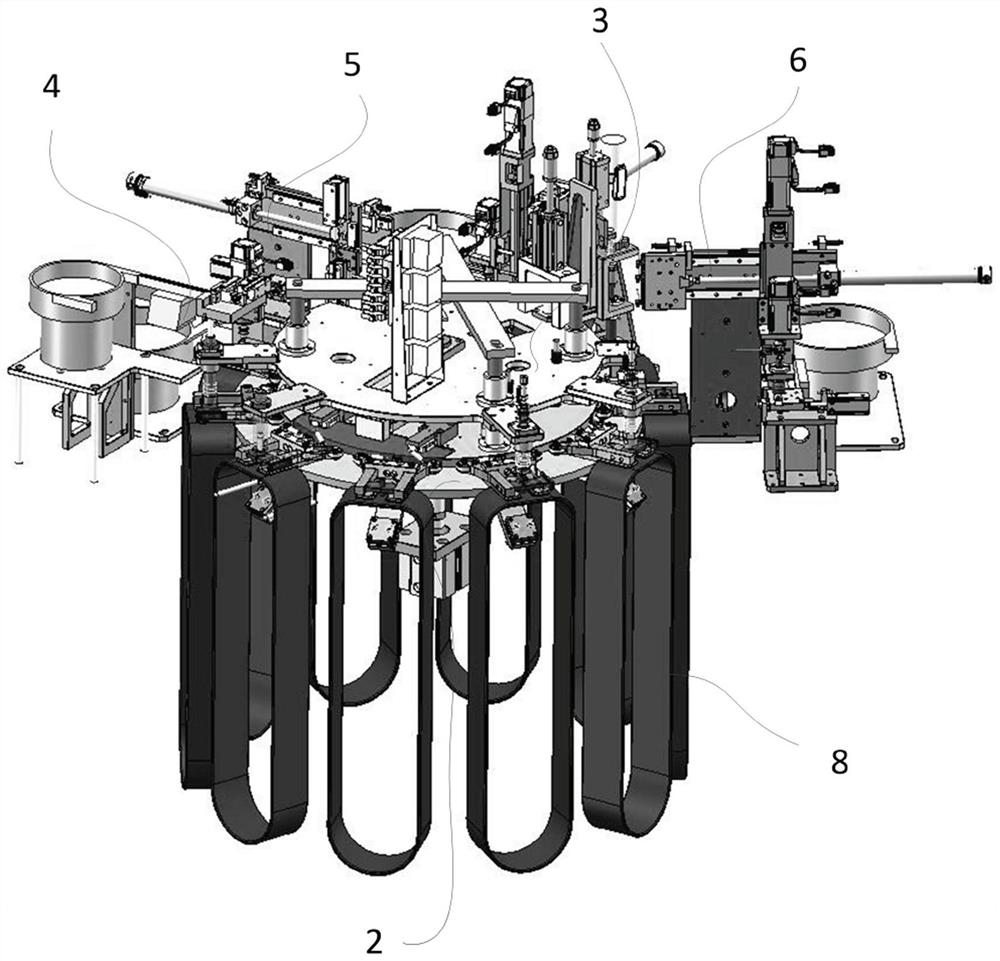

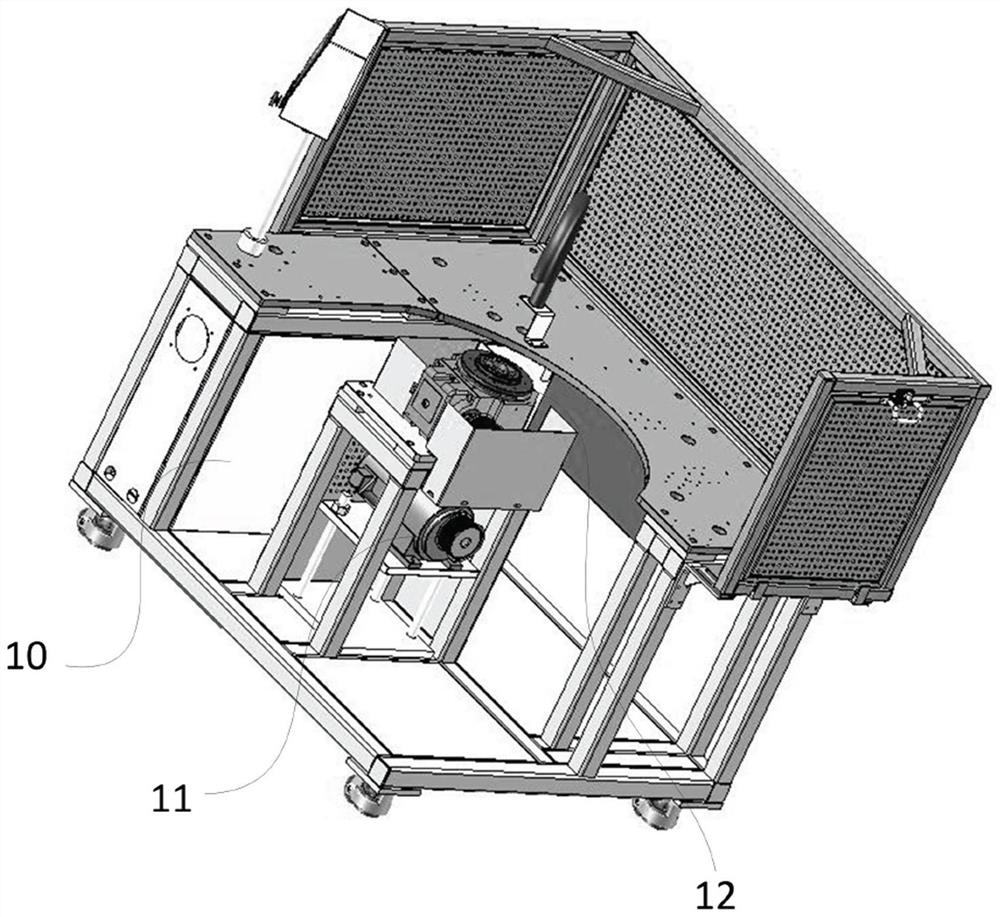

[0058] Such as Figure 1 to Figure 20 As shown, this embodiment provides an automatic assembly machine for tire inner tube parts, which includes a frame module 1, a ten-station rotary module 2 fixed on the frame module 1 for hanging and adjusting the position of the tire inner tube , the ten-station jacking module 3 that is arranged on the top of the ten-station rotary module 2 and is used to fasten the nut of the tire inner tube is fixed on the frame module 1 for providing the valve to the tire inner tube 8 and The valve is installed on the valve feeding module 4 on the tire inner tube, and is fixed on the frame module 1, and is used to provide the gasket to the tire inner tube and set the gasket on the valve. Group 5, fixed on the frame module 1, used to provide nuts to the inner tube of the tire and rotate the nut pre-tightening module 6 set on the valve, and respectively with the ten-station rotation module 2, ten-station rotation module 6 Station jacking module 3, valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com